Auxiliary composition, linear low density polyethylene composition and preparation method, and polyethylene cast packaging film

A linear low-density, polyethylene technology, applied in the direction of transportation and packaging, packaging, wrapping paper, etc., can solve the problems of insufficient flatness of products, poor fluidity of materials, poor quality, etc., and achieve melt pressure drop and fluidity The effect of raising and lowering the processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

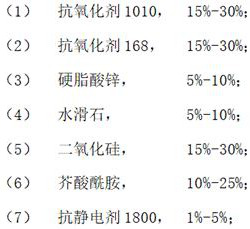

[0025] The second aspect of the present invention provides the preparation method of the above-mentioned additive composition, comprising: 15-30 parts by weight of antioxidant 1010, 15-30 parts by weight of antioxidant 168, 5-10 parts by weight of zinc stearate , 5-10 parts by weight of hydrotalcite, 15-30 parts by weight of silicon dioxide, 10-25 parts by weight of erucamide and 1-5 parts by weight of antistatic agent 1800 are mixed to obtain an auxiliary agent composition.

[0026] A third aspect of the present invention provides a linear low-density polyethylene composition, wherein the linear low-density polyethylene composition comprises: based on the total weight of the linear low-density polyethylene composition, containing 94-97% by weight of A linear low-density polyethylene and 3-6% by weight of the aforementioned additive composition, wherein the linear low-density polyethylene has a melt index of 4-5g / 10min and a density of 0.93- 0.935g / cm 3 .

[0027] In the pre...

Embodiment 1

[0048] (1) preparation auxiliary composition:

[0049] Based on the total weight of the additive composition, antioxidant 1010 with a content of 25% by weight, antioxidant 168 with a content of 20% by weight, zinc stearate with a content of 8% by weight, and Zinc stearate with a content of 8% by weight Hydrotalcite, silicon dioxide with a content of 21% by weight, erucamide with a content of 15% by weight and antistatic agent 1800 with a content of 3% by weight were mixed to obtain an auxiliary agent composition.

[0050] (2) Preparation of linear low density polyethylene composition

[0051] (2.1) Prepared by the Unipol gas phase process, the melt index at 190°C under a load of 2.16kg is 4.5g / 10min, and the density is 0.933g / cm 3 Linear low density polyethylene (powder).

[0052] (2.2) The linear low density polyethylene obtained by the step (2.1) of 94 parts by weight and the auxiliary agent composition obtained by the step (1) of 6 parts by weight are blended, and passed ...

Embodiment 2

[0061] (1) preparation auxiliary composition:

[0062] Based on the total weight of the additive composition, the antioxidant 1010 with a content of 15% by weight, the antioxidant 168 with a content of 15% by weight, the zinc stearate with a content of 11% by weight, and the zinc stearate with a content of 9% by weight Hydrotalcite, silicon dioxide with a content of 24% by weight, erucamide with a content of 25% by weight and antistatic agent 1800 with a content of 1% by weight were mixed to obtain an auxiliary agent composition.

[0063] (2) Preparation of linear low density polyethylene composition

[0064] (2.1) Prepared by the Unipol gas phase process, the melt index at 190°C under a load of 2.16kg is 4g / 10min, and the density is 0.930g / cm 3 Linear low density polyethylene (powder).

[0065] (2.2) The linear low-density polyethylene obtained by the step (2.1) of 97 parts by weight and the auxiliary agent composition obtained by the step (1) of 3 parts by weight are blend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com