Temperature-resistance salt-resistance foam profile controlling and displacement system suitable for complex oil reservoirs and preparation method and application of system

An oil-displacing method and system technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of inapplicability to high temperature, high-salt reservoirs, poor temperature and salt resistance, complicated preparation methods, etc. Improved profile control efficiency, reduced solubility, and excellent temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

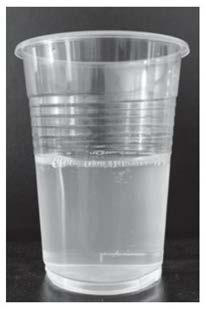

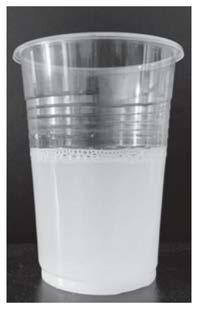

Image

Examples

preparation example Construction

[0050] In a second aspect, the present invention provides a method for preparing the above-mentioned control and flooding system, which specifically includes the following steps:

[0051] (1) cetyltrimethylammonium bromide is added to dissolve in water to obtain cetyltrimethylammonium bromide solution;

[0052] (2) adding nano-titanium dioxide to cetyltrimethylammonium bromide solution to obtain a uniformly dispersed mixed solution of nano-titanium dioxide;

[0053] (3) Add partially hydrolyzed polyacrylamide into the mixed solution and stir evenly to obtain a control and flooding system.

[0054] In a specific embodiment, the preparation method of the control and flooding system comprises the following steps:

[0055] (1) At 25°C, first add the surfactant CTAB into the water, stir with a magnetic stirrer to fully dissolve the surfactant CTAB, and obtain a CTAB aqueous solution;

[0056] (2) Add nano-TiO dropwise in CTAB aqueous solution 2 , sonicated after stirring to make...

Embodiment 1

[0083] The composition (percentage by weight) of the control and drive system of the present embodiment is: the particle diameter is the hydrophilic type TiO of 30nm 2 2% of particles, 0.9% of CTAB, 0.1% of HPAM with a molecular weight of 7 million and a degree of hydrolysis of 10%, and the balance is simulated mineralized water with a total salinity of 220,000 mg / L (where Ca 2+ with Mg 2+ The ion concentration is 2000mg / L).

[0084] The preparation method of the regulating and flooding system of the present embodiment is:

[0085] (1) At 25°C, add the surfactant CTAB into the simulated mineralized water with a total salinity of 220,000 mg / L, stir with a magnetic stirrer for 3 to 5 minutes to fully dissolve the surfactant CTAB, and obtain a CTAB aqueous solution;

[0086] (2) Add hydrophilic TiO with a particle size of 30nm dropwise in the CTAB aqueous solution 2 Particles, stirred for 3 to 5 minutes and then ultrasonicated for 30 minutes to make nano-TiO 2 Uniformly dispe...

Embodiment 2

[0095] The composition (percentage by weight) of the control and drive system of the present embodiment is: the particle diameter is the hydrophilic type TiO of 30nm 2 1% of particles, 0.5% of CTAB, 0.2% of HPAM with a molecular weight of 7 million and a degree of hydrolysis of 10%, and the balance is simulated mineralized water with a total salinity of 220,000mg / L (where Ca 2+ with Mg 2+ The ion concentration is 2000mg / L).

[0096] The preparation method of the regulating and flooding system of the present embodiment is:

[0097] (1) At 25°C, add the surfactant CTAB into the simulated mineralized water with a total salinity of 220,000 mg / L, stir with a magnetic stirrer for 3 to 5 minutes to fully dissolve the surfactant CTAB, and obtain a CTAB aqueous solution;

[0098] (2) Add hydrophilic TiO with a particle size of 30nm dropwise in the CTAB aqueous solution 2 Particles, stirred for 3 to 5 minutes and then ultrasonicated for 30 minutes to make nano-TiO 2 Uniformly disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com