Application and method of fucoidan and its hydrolyzed oligosaccharides in the preparation of probiotic protective agent

A technology of fucoidan and probiotics, applied in the direction of being fixed on/in an organic carrier, etc., to achieve the effects of improving biological efficacy, good stress resistance, and improving survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

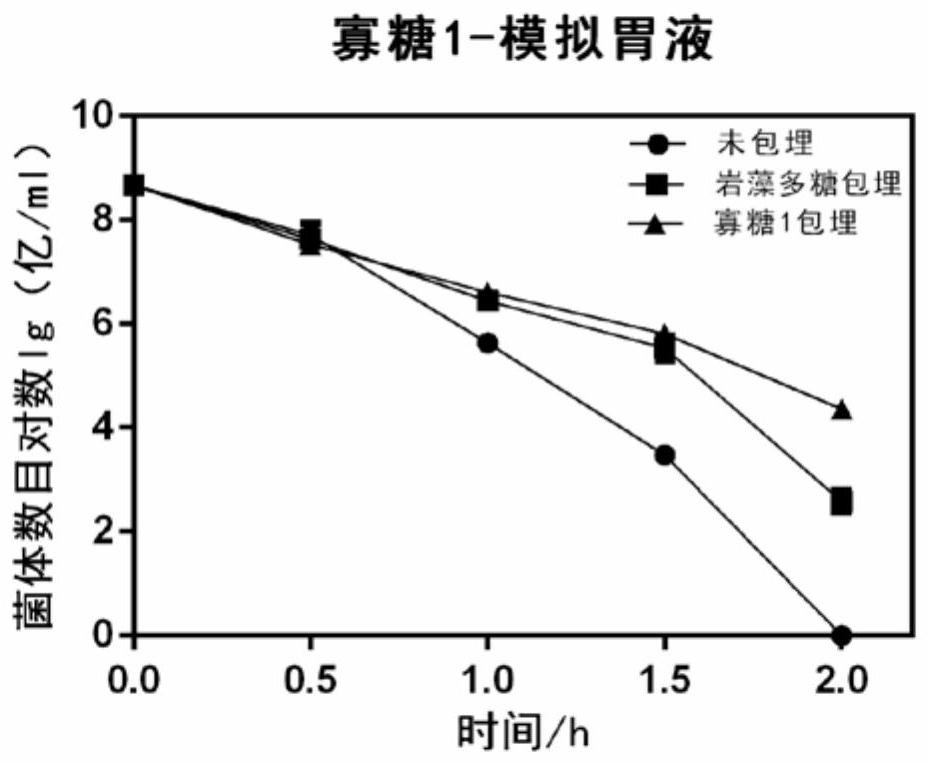

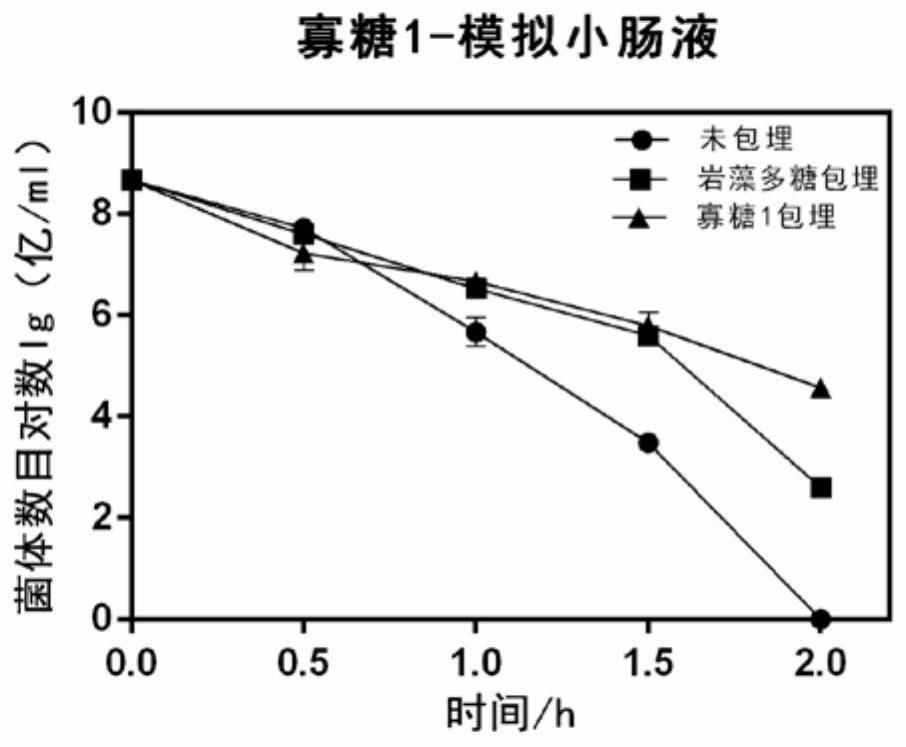

[0043] Embodiment 1, the impact of embedding oligosaccharide 1 on the growth of Bacillus subtilis

[0044] Probiotic treatment: Centrifuge the Bacillus subtilis fermentation broth at 4°C and 4000×g for 10 minutes, wash it twice with PBS, suspend the precipitated cells evenly in the same PBS (pH7.0), and store them at 4°C spare.

[0045] Unembedded group: Spin 2ml of concentrated Bacillus subtilis solution with 10ml of pH=7 NaCl solution for 30min to form a monolayer embedded group (simple mixing).

[0046] Fucoidan embedding preparation: 2mL concentrated Bacillus subtilis liquid (20~70*10 7 CFU) was mixed with 10 mL of fucoidan with a concentration of 20 g / L, and rotated for 30 min to make a monolayer embedding group (simple mixing).

[0047] Oligosaccharide 1 embedding preparation: Mix 2 mL of concentrated Bacillus subtilis solution with 10 mL of 20 g / L oligosaccharide 1, and rotate for 30 minutes to make a monolayer embedding group (simple mixing).

[0048]The non-embedde...

Embodiment 2

[0053] Embodiment 2, the impact of embedding oligosaccharide 2 on the growth of Bacillus subtilis

[0054] Probiotic treatment: Bacillus subtilis fermentation broth was centrifuged at 4000×g for 10 min at 4°C, washed twice with PBS, and the pelleted cells were suspended evenly in the same PBS (pH7.0), and stored at 4°C for later use.

[0055] Unembedded group: Spin 2ml of concentrated Bacillus subtilis solution with 10ml of pH7NaCl solution for 30min to form a monolayer embedded group (simple mixing).

[0056] Preparation of fucoidan embedding: Mix 2ml of concentrated Bacillus subtilis solution with 10mL of 40g / L fucoidan, and rotate for 30min to make a monolayer embedding group (simple mixing).

[0057] Oligosaccharide 2 embedding preparation: Mix 2ml of concentrated Bacillus subtilis solution with 10mL of 40g / L oligosaccharide 1, and rotate for 30min to make a monolayer embedding group (simple mixing).

[0058] Treat the non-embedded group, fucoidan-embedded group and oligo...

Embodiment 3

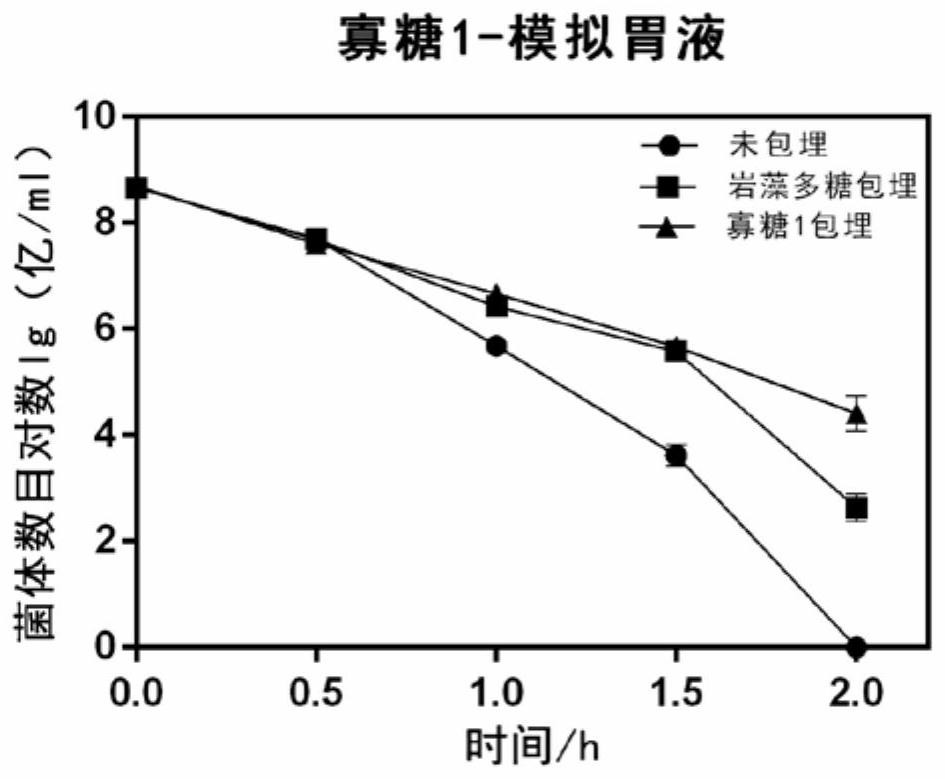

[0063] Example 3, the influence of monolayer embedded oligosaccharide 1 on the growth of Ruvermyces maximus

[0064] Probiotics treatment: centrifuge the fermentation broth of Ruvermyces maximus at 4000×g for 10 min at 4°C, wash it twice with PBS repeatedly, suspend the pelleted cells evenly in the same PBS (pH 7.0), and store them at 4°C for later use.

[0065] Unembedded group: Rotate 2ml concentrated Ruvermyces marx solution with 10ml pH7NaCl solution for 30min to form a monolayer embedded group (simple mixing).

[0066] Preparation of fucoidan embedding: Mix 2ml of concentrated Ruvermyces maximus with 10mL of 40g / L fucoidan, and rotate for 30min to make a monolayer embedding group (simple mixing).

[0067] Preparation of oligosaccharide 1 embedding: Mix 2ml of concentrated R. marxensis solution with 10mL of 40g / L oligosaccharide 1, and rotate for 30min to make a monolayer embedding group (simple mixing).

[0068] Treat the non-embedded group, fucoidan-embedded group and o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com