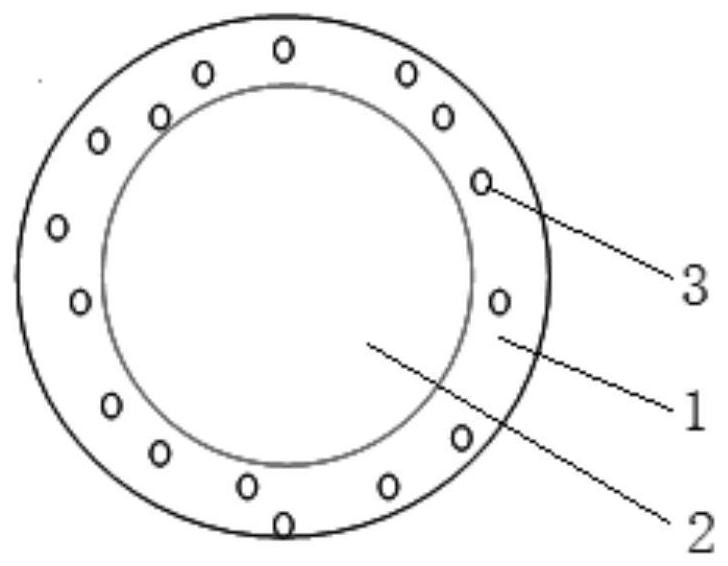

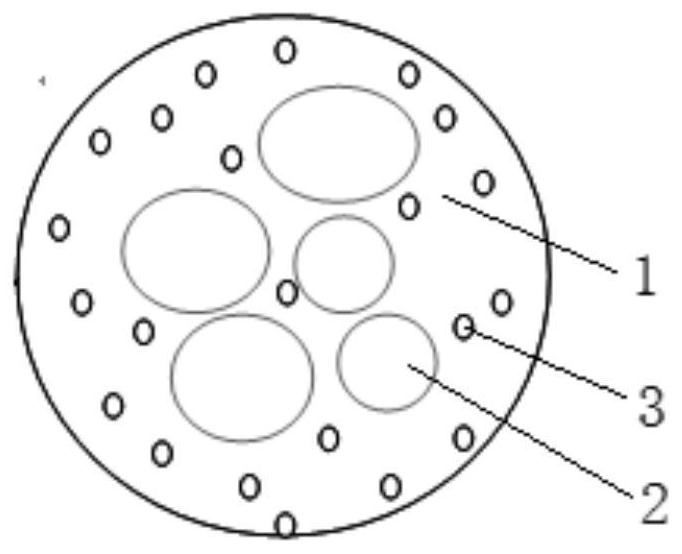

A kind of artificial storage stone and preparation method thereof

A man-made, water storage cavity technology, applied in the direction of side ditches/curbs, roads, pavement details, etc., it can solve the problems of natural stones easily destroying the natural environment, difficult construction, and high bulk density, etc., to reduce the amount of deep pit excavation. , The effect of low construction difficulty and low bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] An artificial water storage stone, prepared from the following raw materials in parts by weight: 50g of recycled concrete fine aggregate, 41.5g of cement binder, 6.2g of water, 7g of polyphenylene particles, 0.3g of polycarboxylate superplasticizer, and Base cellulose 1.2g.

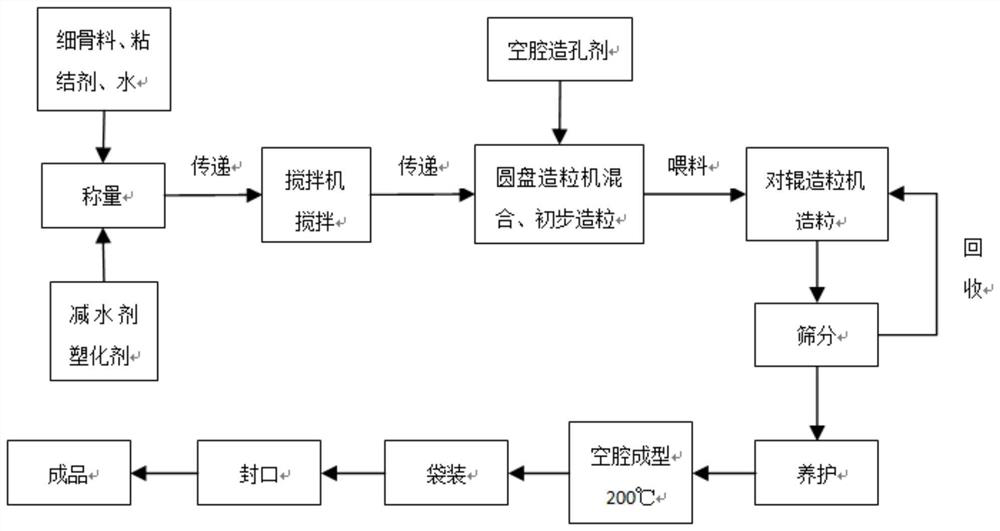

[0041] In this embodiment, the water storage stone is prepared by the following method:

[0042] (1) Add the recycled concrete fine aggregate, cement binder, water, polycarboxylate superplasticizer and methyl cellulose into the mixer according to the weight part, stir evenly, pour it into the disc granulator, and then put it into the disc granulator according to the weight part Add polystyrene particles for mixing and primary granulation;

[0043] (2) Feed the preliminarily made granules in step (1) into the double-roll granulator to granulate again, and then use the sieving machine to sieve, and recycle the products that do not meet the pore size requirements and return them to the double-roll gr...

Embodiment 2

[0046] An artificial water storage stone, prepared from the following raw materials in parts by weight: 60g of recycled brick fine aggregate, 35g of active powder concrete, 7.3g of water, 3g of polyphenylene particles, 0.5g of polycarboxylate superplasticizer, lignin sulfonate 0.3g of sodium nitrate, 0.4g of methyl cellulose, and 0.8g of polyvinyl alcohol.

[0047] In this embodiment, the water storage stone is prepared by the following method:

[0048] (1) Add regenerated brick fine aggregate, active powder concrete, water, polycarboxylate superplasticizer, sodium lignosulfonate, methyl cellulose, and polyvinyl alcohol into the mixer by weight and stir evenly, then pour into the disc In the granulator, polystyrene particles are added in parts by weight for mixing and preliminary granulation;

[0049] (2) Feed the preliminarily made granules in step (1) into the double-roll granulator to granulate again, and then use the sieving machine to sieve, and recycle the products that...

Embodiment 3

[0052] An artificial water storage stone, prepared from the following raw materials in parts by weight: 70g of recycled concrete fine aggregate, 26g of active powder concrete, 7.8g of water, 1g of polyphenylene particles, 0.8g of polycarboxylate superplasticizer, lignin sulfonate 0.7g of sodium phosphate, 0.2g of methylcellulose, and 1.3g of polyvinyl alcohol.

[0053] In this embodiment, the water storage stone is prepared by the following method:

[0054] (1) Add recycled concrete fine aggregate, active powder concrete, water, polycarboxylate superplasticizer, sodium lignosulfonate, methyl cellulose, and polyvinyl alcohol into the mixer by weight and stir evenly, then pour into the disc In the granulator, polystyrene particles are added in parts by weight for mixing and preliminary granulation;

[0055] (2) Feed the preliminarily made granules in step (1) into the double-roll granulator to granulate again, and then use the sieving machine to sieve, and recycle the products ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com