Dispersed solid-phase extraction material, preparation method and application thereof

A technology of dispersing solid phase and extraction, applied in the direction of analysis of materials, material separation, material inspection products, etc., can solve the problems of cumbersome operation process, high detection cost, consumption, etc., and achieve broad application prospects, low matrix interference, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

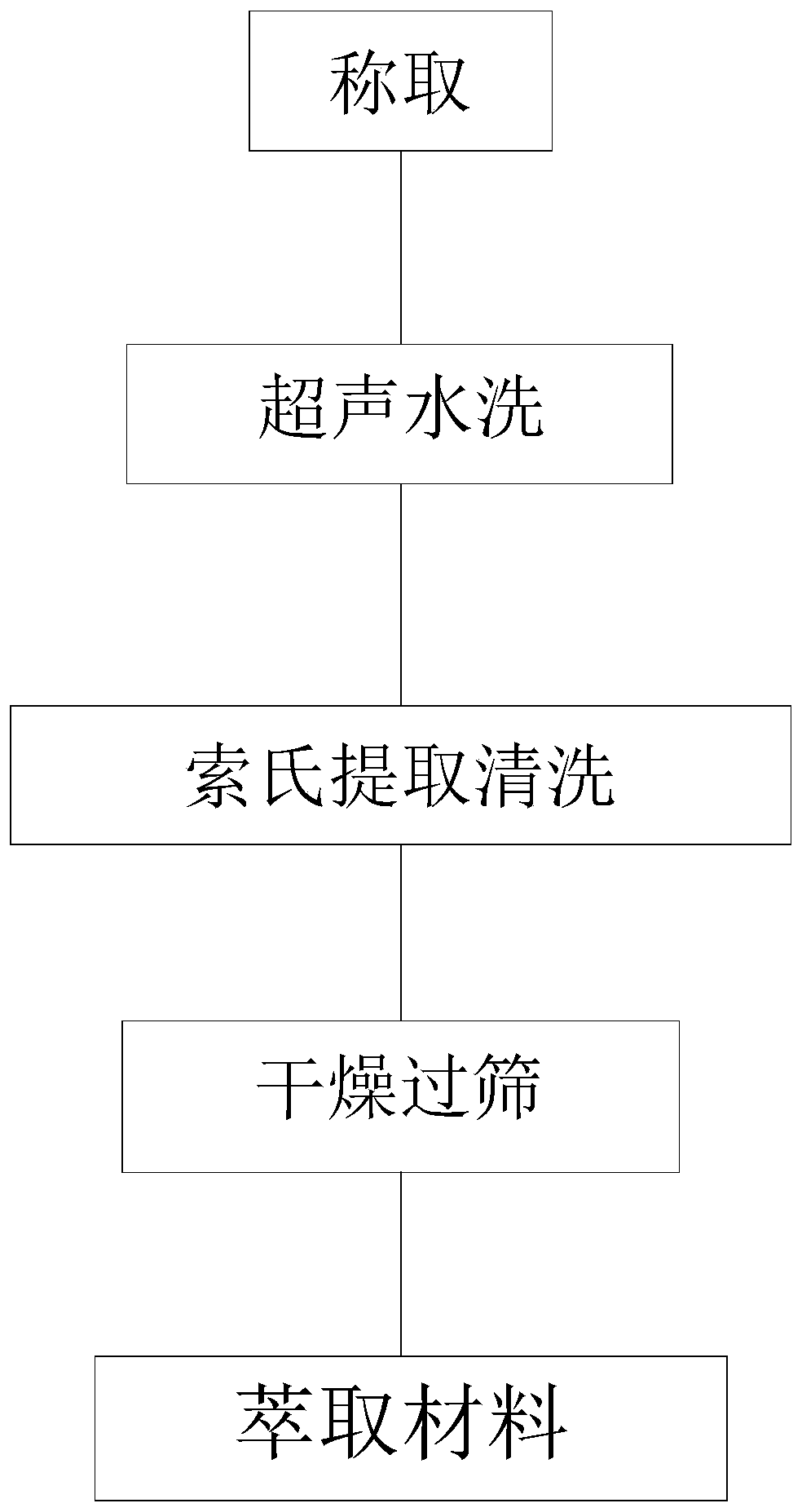

[0037] The application provides a method for preparing a dispersed solid phase extraction material, comprising the following steps:

[0038]S1. Weigh 5g of the humic acid sample sold in China and put it into a 1L beaker, add 500mL of water, fully stir and disperse, put the beaker into an ultrasonic instrument, and perform ultrasonic cleaning. The time of ultrasonic cleaning is 15min. Set aside for 8 hours, remove the supernatant, add 500mL of water again, perform ultrasonic cleaning for 15 minutes, let stand for 8 hours, remove the supernatant, repeat the above steps 10 times, until the supernatant has no obvious light yellow phenomenon under natural light; If the particles in the beaker are not completely settled after standing for 8 hours during the standing process of the sample, repeat the above steps for 10 times of cleaning; Min speed, centrifuge for 6min, centrifuge to obtain solid precipitate, transfer the precipitate to a 75mL evaporating dish with acetone, heat the e...

Embodiment 2

[0043] The application provides a method for preparing a dispersed solid phase extraction material, comprising the following steps:

[0044] S1. Weigh 5g of the humic acid sample sold in China and put it into a 1L beaker, add 500mL of water, fully stir and disperse, put the beaker into an ultrasonic instrument, and perform ultrasonic cleaning. The time of ultrasonic cleaning is 12min. Set aside for 8 hours, remove the supernatant, add 500mL of water again, perform ultrasonic cleaning for 12 minutes, let stand for 8 hours, remove the supernatant, repeat the above steps 10 times, until the supernatant has no obvious light yellow phenomenon under natural light; If the particles in the beaker are not completely settled after standing for 8 hours during the standing process of the sample, repeat the above steps for 10 times of cleaning; Min speed, centrifuge for 6min, centrifuge to obtain solid precipitate, transfer the precipitate to a 75mL evaporating dish with acetone, heat the ...

Embodiment 3

[0049] The application provides a method for preparing a dispersed solid phase extraction material, comprising the following steps:

[0050] S1. Weigh 5g of the humic acid sample sold in China and put it into a 1L beaker, add 500mL of water, fully stir and disperse, put the beaker into an ultrasonic instrument, and perform ultrasonic cleaning. The time of ultrasonic cleaning is 16min. Leave for 7 hours, remove the supernatant, add 500mL of water again, perform ultrasonic cleaning for 16 minutes, let stand for 7 hours, remove the supernatant, repeat the above steps 10 times, until the supernatant has no obvious light yellow phenomenon under natural light; If the particles in the beaker are not completely settled after standing for 8 hours during the standing process of the sample, repeat the above steps for 10 times of cleaning; Min speed, centrifuge for 6min, centrifuge to obtain solid precipitate, transfer the precipitate to a 75mL evaporating dish with acetone, heat the evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com