Collection method for vacuumizing data of refrigerator on production line

A technology of data collection and collection method, which is applied in the field of collection of refrigerator vacuuming data, and can solve the problems of chaotic process, unstorable vacuum degree value, and high error probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

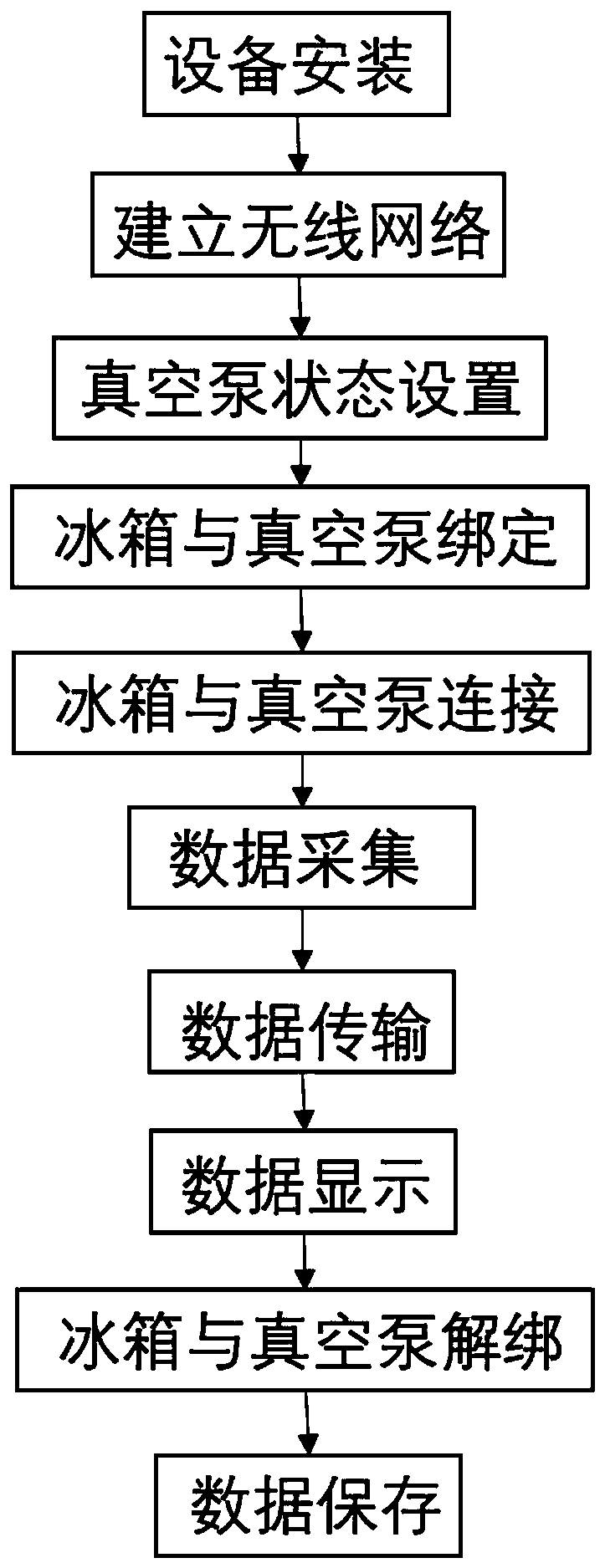

[0030] The collection method of the refrigerator vacuuming data on the production line involved in this embodiment is implemented in the refrigerator vacuuming data collection device on the production line, and the specific data collection process includes the following steps:

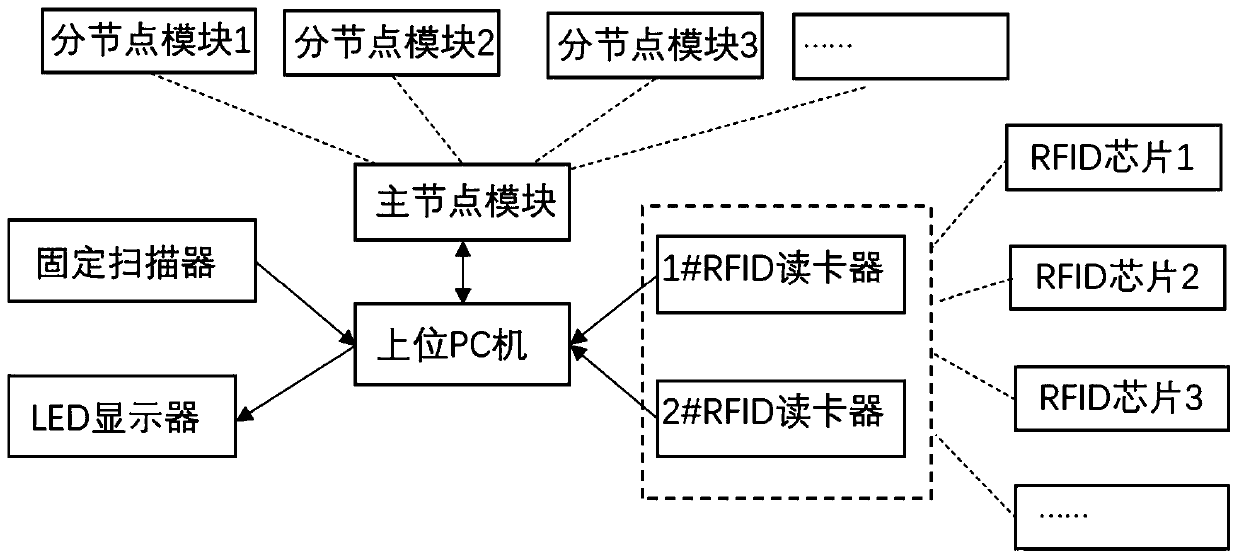

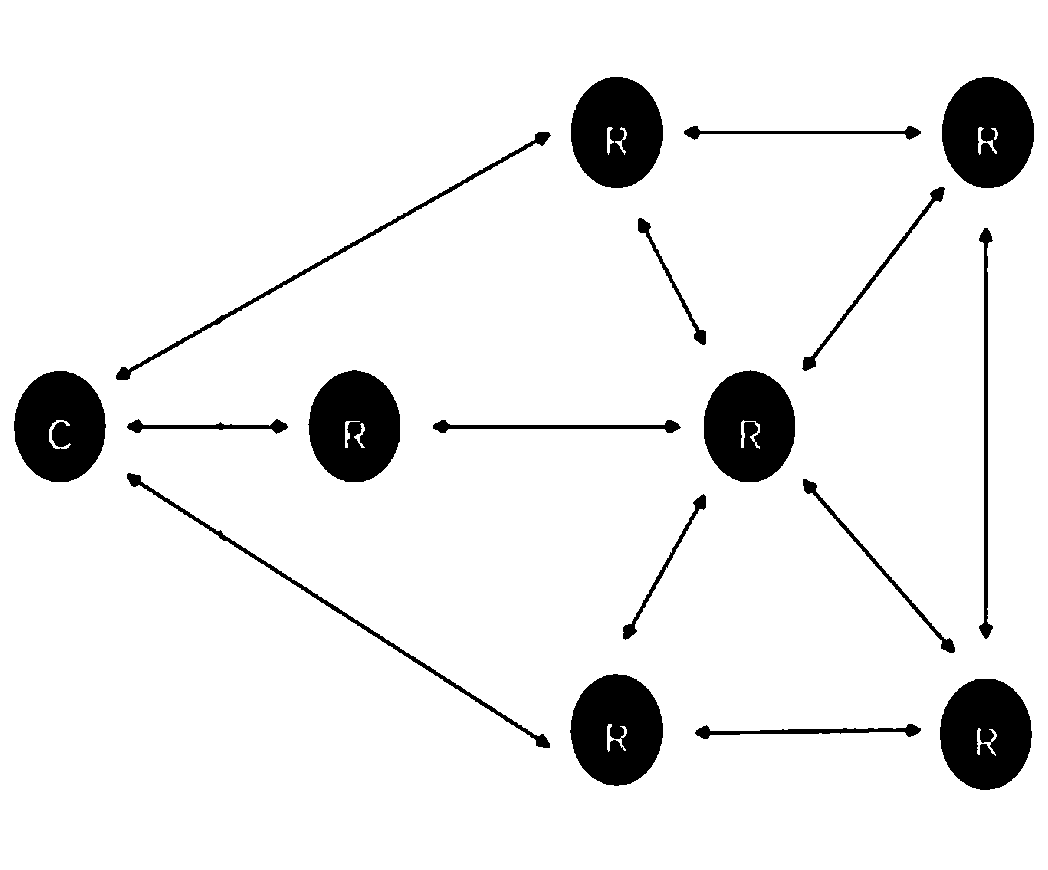

[0031] (1) Equipment installation: Install the corresponding refrigerator vacuum data acquisition related software on the upper PC and start it; set up a manual intubation area on the refrigerator production line in the vacuum section, and fix it in front of the operators in the manual intubation area Install an LED display, and then install a fixed scanner in front of the intubation area. The distance between the fixed scanner and the intubation area is less than or equal to the width of two refrigerators, and then install a radio frequency identification chip on each vacuum pump ( RFID chip for short), and install 1# RFID card reader and 2# RFID card reader in the vacuum pump area. The position of 1# ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com