Core-shell graphene-silicon composite material, preparation method thereof, electrode material and battery

A technology of silicon composite materials and graphene materials, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems of reduced cycle performance, structural damage of silicon-based materials, collapse of electrode structures, etc., to avoid cycle performance degradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

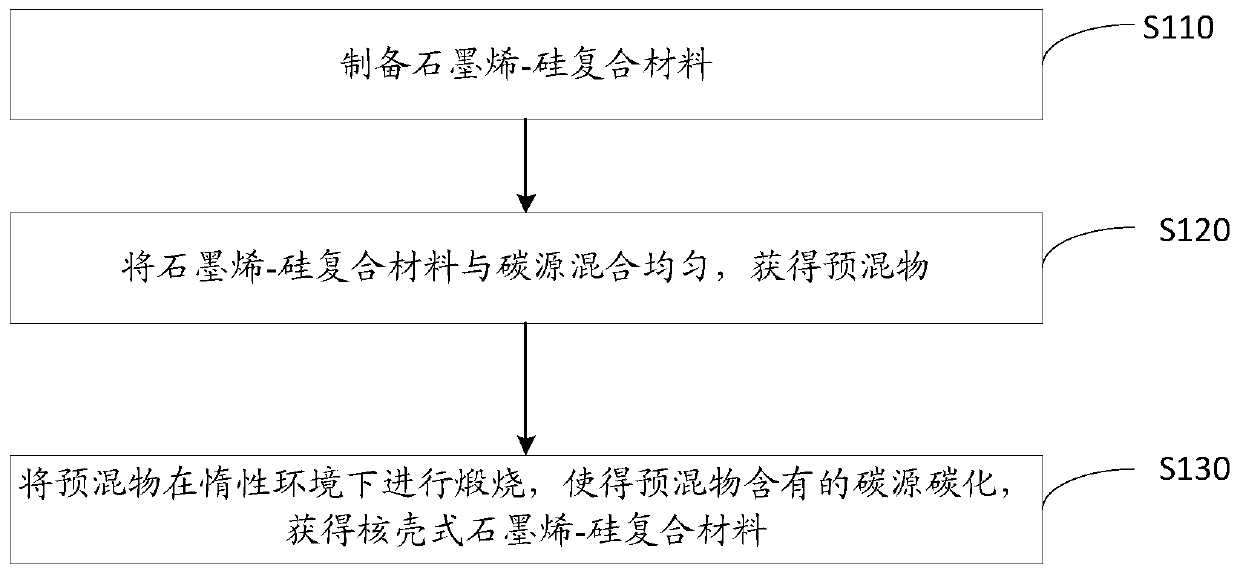

[0032] The embodiments of the present invention provide a core-shell graphene-silicon composite material and a preparation method thereof, so that the formed core-shell graphene-silicon composite material includes a graphene-silicon composite material coated with a carbon layer on the surface; When the core-shell graphene-silicon composite material is applied to the electrode of the battery, the contact between the active ions contained in the electrolyte and the graphene-silicon composite material can be avoided, thereby reducing the concentration of the core-shell graphene-silicon composite material. Degree of silicon expansion. like figure 1 As shown, the preparation method of the core-shell graphene-silicon composite material includes:

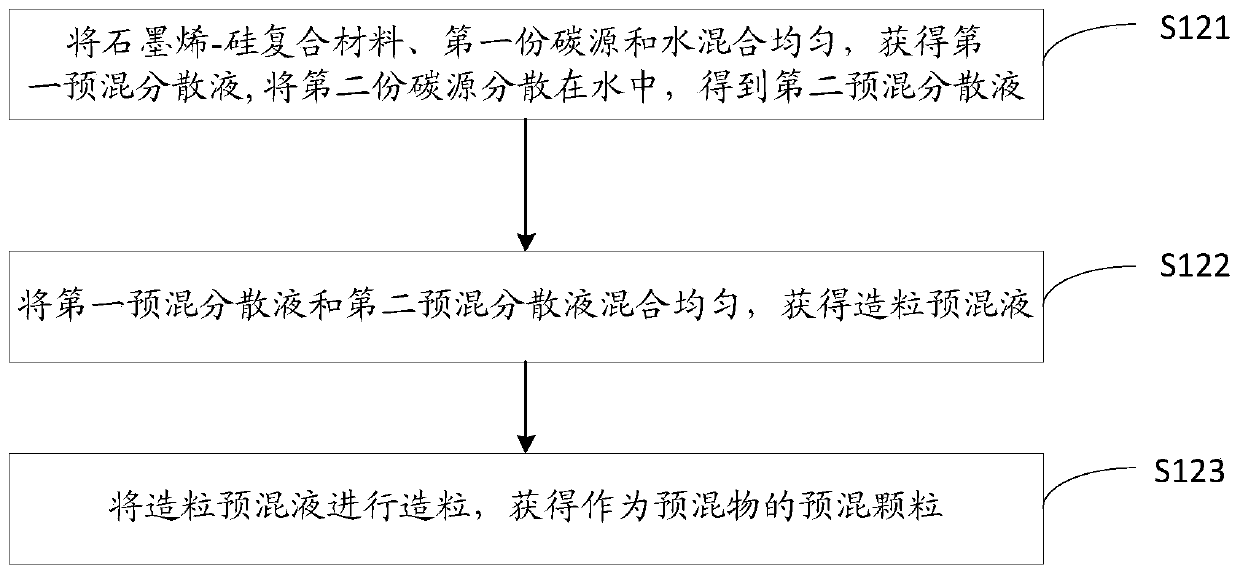

[0033] Step S120: Mixing the graphene-silicon composite material and the carbon source uniformly to obtain a premix; the core-shell graphene-silicon composite material is a self-made graphene-silicon composite material, or a purchased gra...

Embodiment 2

[0079] The embodiment of the present invention also provides a core-shell graphene-silicon composite material, the core-shell graphene-silicon composite material includes a graphene-silicon composite material, and the graphene-silicon composite material can be purchased, or It can be self-made. If it is self-made, it can be prepared by referring to the preparation method of the graphene-silicon composite material described in Embodiment 1. The surface of the graphene-silicon composite material is covered with a carbon layer.

[0080] The invention also provides a core-shell graphene-silicon composite material, the core-shell graphene-silicon composite material is the core-shell graphene- Silicon composite.

[0081] Compared with the prior art, the core-shell graphene-silicon composite material provided in the embodiment of the present invention has the same beneficial effects as the above-mentioned preparation method of the core-shell graphene-silicon composite material, which...

Embodiment 3

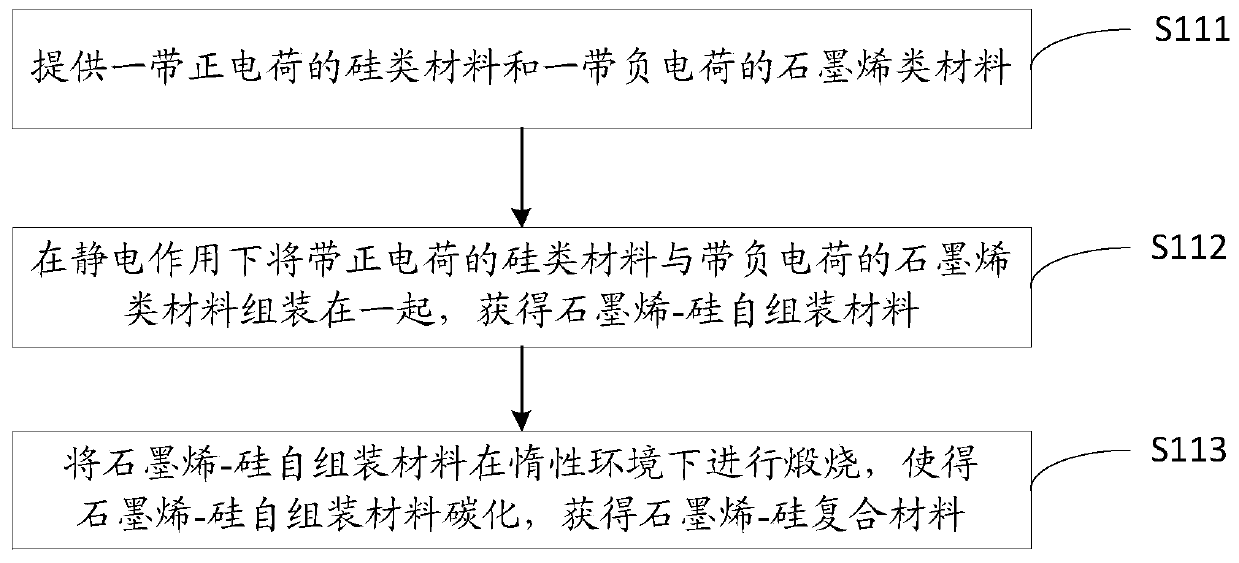

[0083] An embodiment of the present invention provides a method for preparing a graphene-silicon composite material, comprising the following steps:

[0084] In the first step, 2g of nano-silicon with a particle size of 80nm-200nm is dispersed in 500mL of ethanol, and ultrasonically dispersed for 1.5h to obtain a nano-silicon ethanol dispersion; 8mL of 5% ammonia water is added dropwise to the nano-silicon ethanol dispersion. , to obtain an alkaline nano-silicon dispersion with pH=9; add 4 g of 3-aminopropyltriethoxysilane dropwise to the alkaline nano-silicon dispersion, and stir mechanically for 5 h at room temperature to obtain a positively charged Dispersion of silicon-based materials; centrifuge the dispersion containing positively charged silicon-based materials with a centrifuge, collect the precipitate obtained by centrifugation, and then wash the precipitate three times with high-purity water centrifugation. After drying for 10 hours, the aminated nano-silicon was obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com