Preparation method of carbon nanotube composite material

A carbon nanotube and composite material technology, which is applied in the field of carbon nanotube composite material preparation, can solve the problems of poor cycle life, unstable composite material structure, low specific capacitance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of carbon nanotube composite material, comprising the following steps:

[0023] (1) Preparation of nickel-based Prussian blue analogs as precursors by normal temperature precipitation method, including the following steps: Step 1, preparation of solution I: mix 1.8mmol nickel nitrate, 2.7mmol sodium citrate and 60mL deionized water as solution I; Step 2, preparation of solution II: dissolving 1.2 mmol potassium cobaltcyanide in 60 mL of deionized water to obtain solution II; step 3, preparation of nickel-based Prussian blue analogues: quickly pour solution I into solution II, and magnetically stir for 1 min, Stand at room temperature for 24 hours, wash with deionized water and absolute ethanol three times, and dry at 70°C for 12 hours to obtain nickel-based Prussian blue analogue powder;

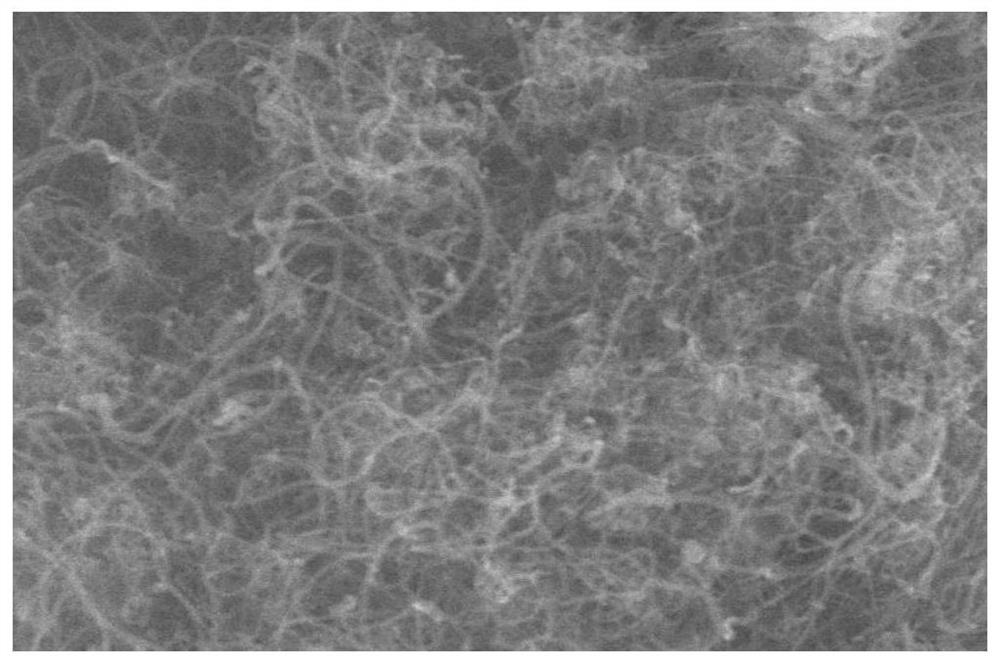

[0024] (2) The preparation method of carbon nanotube-encapsulated metal particles comprises the following steps: step 1, spreading the nickel-based Prussian blue ...

Embodiment 2

[0027] A preparation method of carbon nanotube composite material, comprising the following steps:

[0028] (1) Preparation of nickel-based Prussian blue analogs as precursors by normal temperature precipitation method, including the following steps: Step 1, preparation of solution I: mix 1.8mmol nickel nitrate, 2.7mmol sodium citrate and 60mL deionized water as solution I; Step 2, preparation of solution II: dissolving 1.2 mmol potassium ferricyanide in 60 mL of deionized water to obtain solution II; step 3, preparation of nickel-based Prussian blue analogues: quickly pour solution I into solution II, and magnetically stir for 1 min. Stand at room temperature for 20 hours, wash with deionized water and absolute ethanol three times, and dry at 60°C for 12 hours to obtain nickel-based Prussian blue analogue powder;

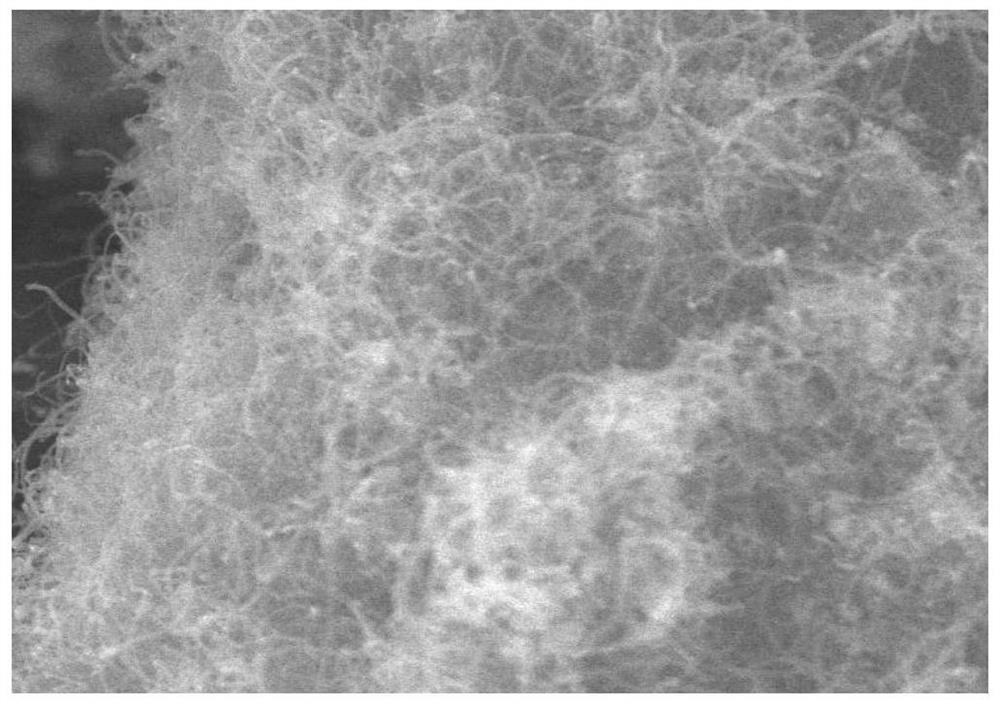

[0029] (2) The preparation method of carbon nanotube-encapsulated metal particles comprises the following steps: step 1, spreading the nickel-based Prussian blue a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com