Asphalt concrete road surface construction method

A technology of asphalt concrete and construction method, which is applied to cohesive pavement paved on site, roads, roads, etc., which can solve the problems of limiting the speed of urban vehicles, bumpy urban vehicles, uneven road surface, etc., and achieve improved stability , uniform distribution, and the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

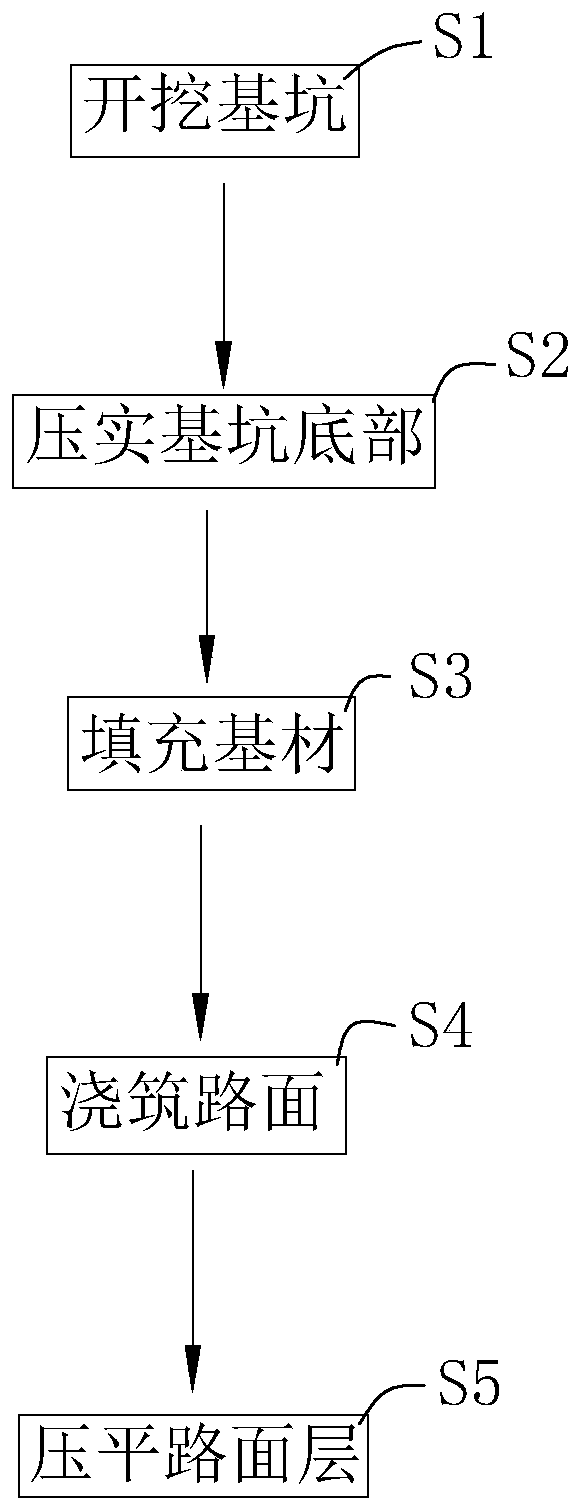

[0061] A kind of bituminous concrete pavement construction method, with reference to figure 1 , including the following steps:

[0062] S1. Excavation of foundation pit, details are as follows:

[0063] Excavate the foundation pit according to the direction of the road in the design drawing.

[0064] S2. Compact the bottom of the foundation pit, as follows:

[0065] The bottom of the foundation pit is compacted by a road roller, and then a waterproof asphalt membrane is laid on the bottom of the foundation pit.

[0066] S3. Fill the base material, as follows:

[0067] Put natural rock block into foundation pit, natural rock block adopts granite, and the maximum size of natural rock block is length 50cm, width 50cm, height 50cm, and adjacent natural rock block is close to.

[0068] S4. Pouring the road surface, specifically as follows:

[0069]Pour asphalt concrete to form the pavement layer, and the top height of the pavement layer is 5cm higher than the top height of the...

Embodiment 2

[0074] A preparation method of asphalt concrete, specifically as follows:

[0075] a. Add 15kg of Portland cement and 20kg of water into the stirring tank at a speed of 30r / min, and stir for 5min to form cement slurry;

[0076] b. Add 100kg of asphalt into the cement slurry, rotate at a speed of 45r / min, and stir for 5min to form an asphalt slurry;

[0077] c. Add 30kg of sand, 40kg of stone, 5kg of acrylic acid emulsion, 2kg of casein and 0.5kg of fatty alcohol polyoxyethylene ether into the asphalt slurry, and stir for 8 minutes at a speed of 35r / min to form asphalt concrete.

Embodiment 3

[0079] A preparation method of asphalt concrete, specifically as follows:

[0080] a. Add 17kg of Portland cement and 23kg of water into the stirring tank at a speed of 30r / min and stir for 5min to form cement slurry;

[0081] b. Add 100kg of asphalt into the cement slurry, rotate at a speed of 45r / min, and stir for 5min to form an asphalt slurry;

[0082] c. Add 35kg of sand, 45kg of stone, 5.5kg of acrylic acid emulsion, 2.5kg of casein, and 0.7kg of fatty alcohol polyoxyethylene ether into the asphalt slurry, and stir for 8 minutes at a speed of 35r / min to form asphalt concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com