Semiconductor device and method of forming the same

A semiconductor and device technology, applied in the field of semiconductor devices and their formation, can solve problems such as poor performance of semiconductor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] As mentioned in the background, semiconductor devices formed in the prior art have poor performance.

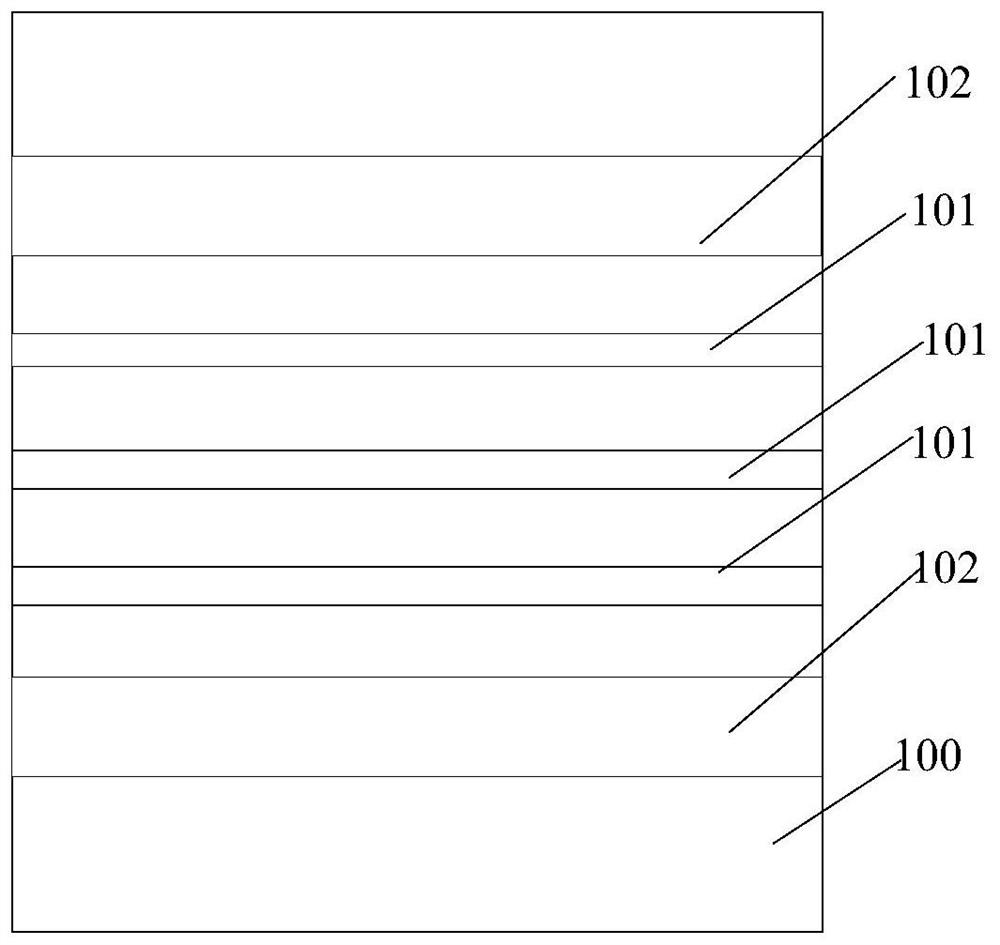

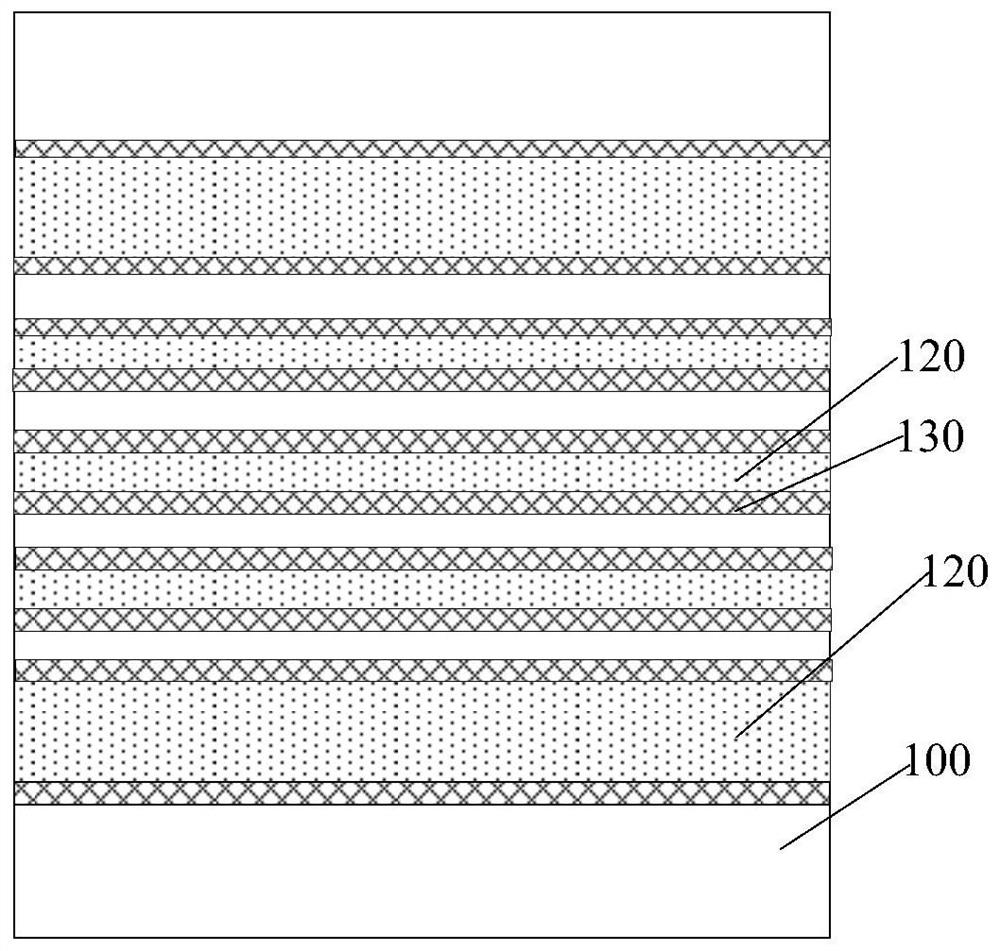

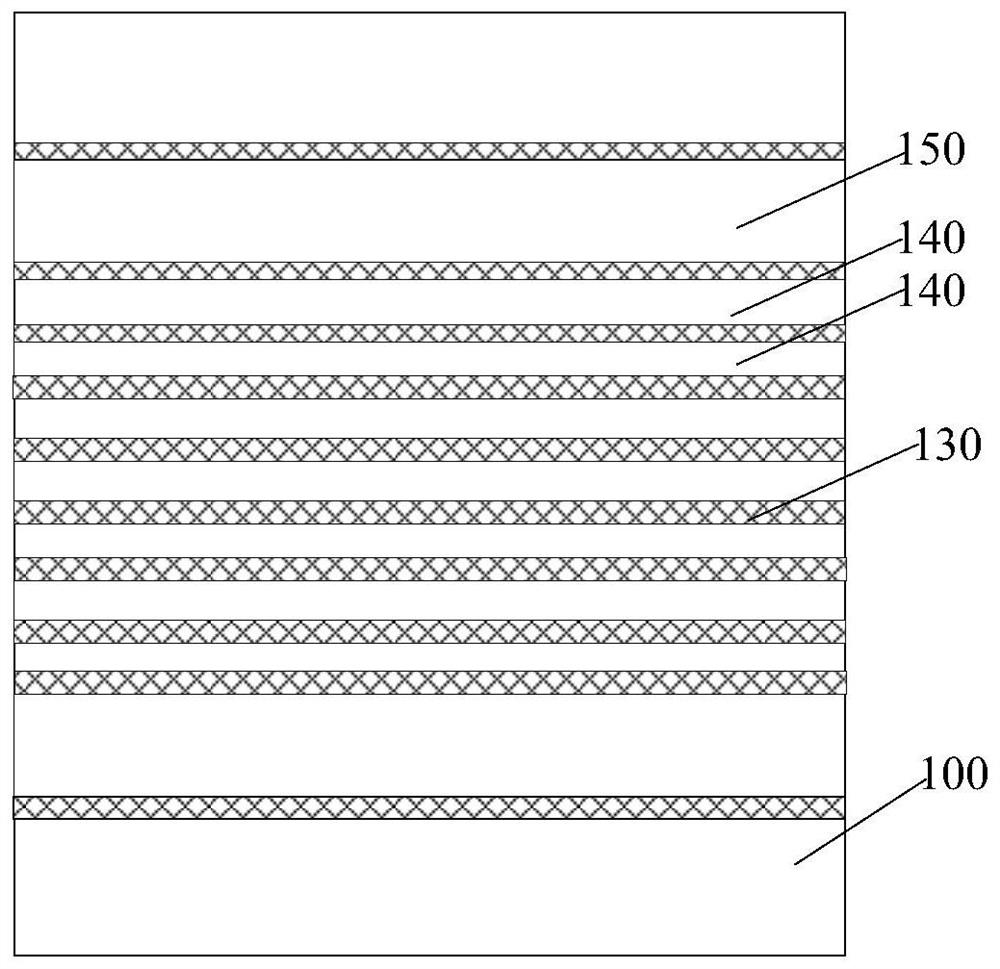

[0032] Figure 1 to Figure 3 It is a structural schematic diagram of the formation process of a semiconductor device.

[0033] refer to figure 1 , providing a dielectric layer 100 , the dielectric layer 100 includes a plurality of discrete first groove areas 101 and a plurality of second groove areas 102 , and the plurality of first groove areas 101 are located between adjacent second groove areas 102 .

[0034] refer to figure 2A sacrificial layer 120 is respectively formed on the first groove region 101 and the second groove region 102 of the dielectric layer 100 ; sidewalls 130 are formed on the sidewalls on both sides of the sacrificial layer 120 .

[0035] refer to image 3 , after forming the spacer 130, remove the sacrificial layer 120 (refer to figure 2 ); after removing the sacrificial layer 120, the dielectric layer 100 is etched with the sidewall 130 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com