Ecological restoration method for quarry in mining area

A technology of ecological restoration and quarry, applied in the direction of soil preparation methods, applications, agricultural machinery and tools, etc., can solve the problems of organic matter decomposition and nitrogen mineralization process inhibition in mining areas, biodiversity attenuation, guest soil is easy to be polluted, etc. To achieve the effect of avoiding the erosion of guest soil, increasing the diversity of mining areas, and weakening the toxicity of mining areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

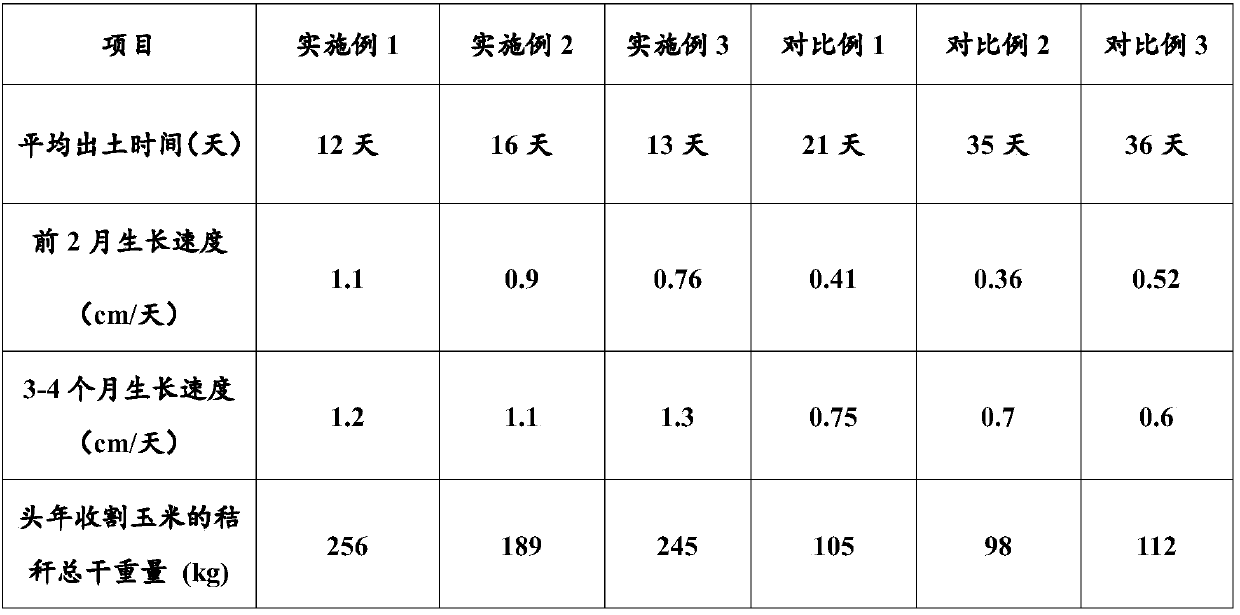

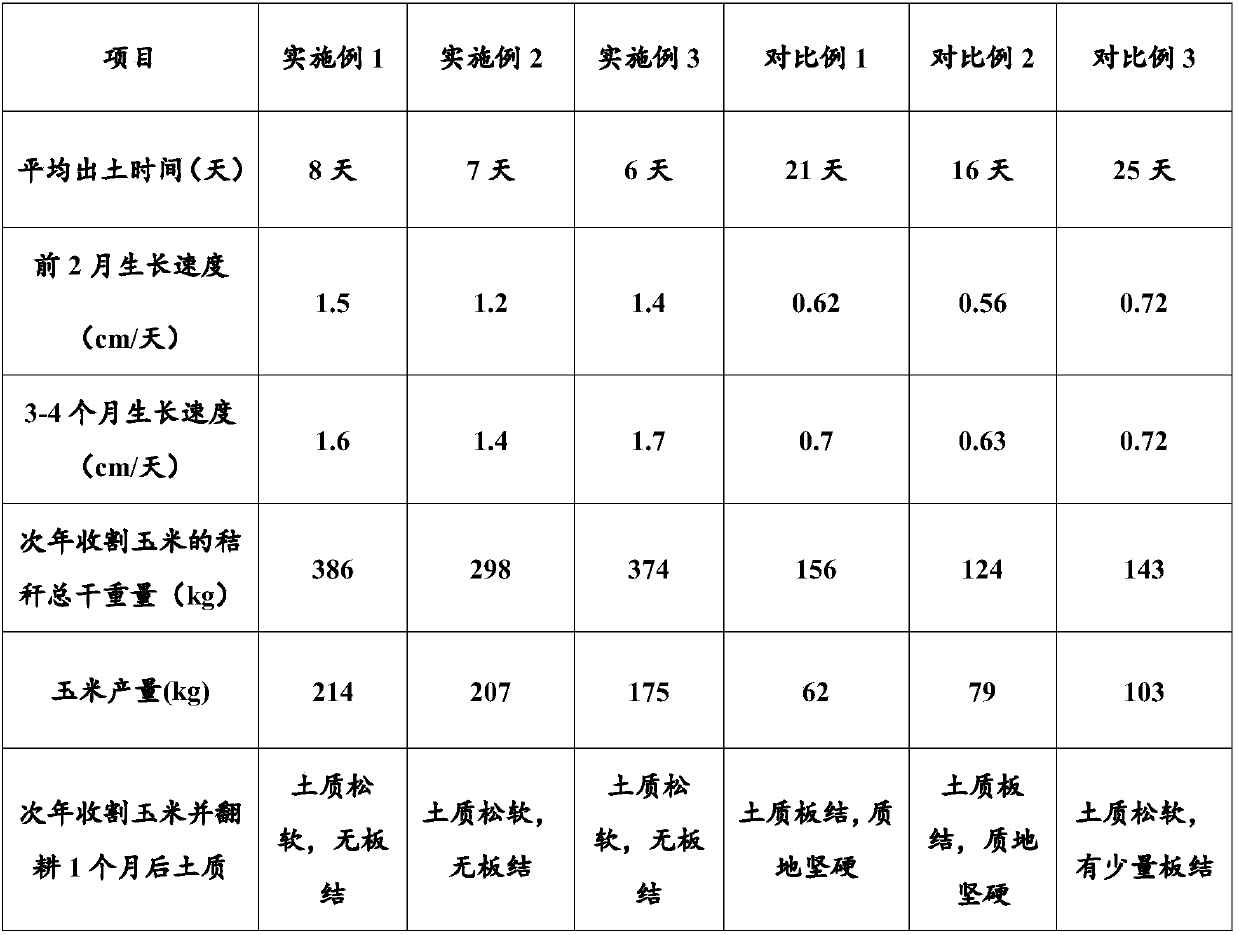

Embodiment 1

[0056] Level the quarry, and crush the abandoned ore to obtain mineral powder, and soak the obtained mineral powder in an aqueous solution of sulfuric acid with a concentration of 12% (the mass ratio of mineral powder is 1:2) for 30 hours, Obtain pretreated mineral powder;

[0057] Mix the pretreated mineral powder, water, and agglomerating agent in a mass ratio of 10:8:5, and then shear at a speed of 12,000 rpm for 1 hour to obtain a slurry; the agglomerating agent is alkali A mixed solution of formula aluminum chloride and polyferric sulfate;

[0058] After laying activated carbon layer, slurry and isolation layer composed of coal gangue and fly ash in the quarry after leveling, compaction is carried out while spraying water. The thickness ratio of activated carbon layer, slurry and isolation layer is is 1:2:1; wherein, in the isolation layer, the mass ratio of coal gangue and fly ash is 5:1;

[0059] Arbor tree trunk (length is 0.5-1 meter) is laid in the quarry after com...

Embodiment 2

[0063] The quarry is leveled, and the waste ore is crushed, and the obtained ore powder is soaked in an aqueous solution of sulfuric acid with a concentration of 20% (the mass ratio of the ore powder is 1:1.5) for 50 hours to obtain a pretreated ore pink;

[0064] After mixing the pretreated mineral powder, water, and agglomerating agent in a mass ratio of 5:5:4, shear at a speed of 15,000 rpm for 1 hour to obtain a slurry; in weight percentage, The agglomerating agent includes: 15% of basic aluminum chloride, 8% of polyferric sulfate, 20% of zinc chloride, 15% of active silicon dioxide, 10% of sodium carbonate and the balance of water.

[0065] After laying activated carbon layer, slurry and isolation layer composed of coal gangue and fly ash in the quarry after leveling, compaction is carried out while spraying water. The thickness ratio of activated carbon layer, slurry and isolation layer is is 1:3:0.5; wherein, in the isolation layer, the mass ratio of coal gangue and fl...

Embodiment 3

[0071] The quarry is leveled, and the waste ore is crushed, and the obtained ore powder is soaked in an aqueous solution of sulfuric acid with a concentration of 40% (the mass ratio of the ore powder is 1:1.5) for 50 hours to obtain a pretreated ore pink;

[0072] After mixing the pretreated mineral powder, water, and agglomerating agent in a mass ratio of 10:9:7, shear at a speed of 15,000 rpm for 1 hour to obtain a slurry; in weight percentage, The agglomerating agent includes: 10% of basic aluminum chloride, 10% of polyferric sulfate, 15% of zinc chloride, 15% of active silicon dioxide, 10% of sodium carbonate and the rest of water.

[0073] After laying activated carbon layer, slurry and isolation layer composed of coal gangue and fly ash in the quarry after leveling, compaction is carried out while spraying water. The thickness ratio of activated carbon layer, slurry and isolation layer is is 1:2:0.5; wherein, in the isolation layer, the mass ratio of coal gangue and fly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com