High-speed centrifuging spray dryer

A spray dryer and high-speed centrifugation technology, applied in spray evaporation, filtration separation, separation methods, etc., can solve the problems of inconvenient material filtration and inconvenient removal of impurities, and achieve the effect of speeding up the filtration speed, simple structure, and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

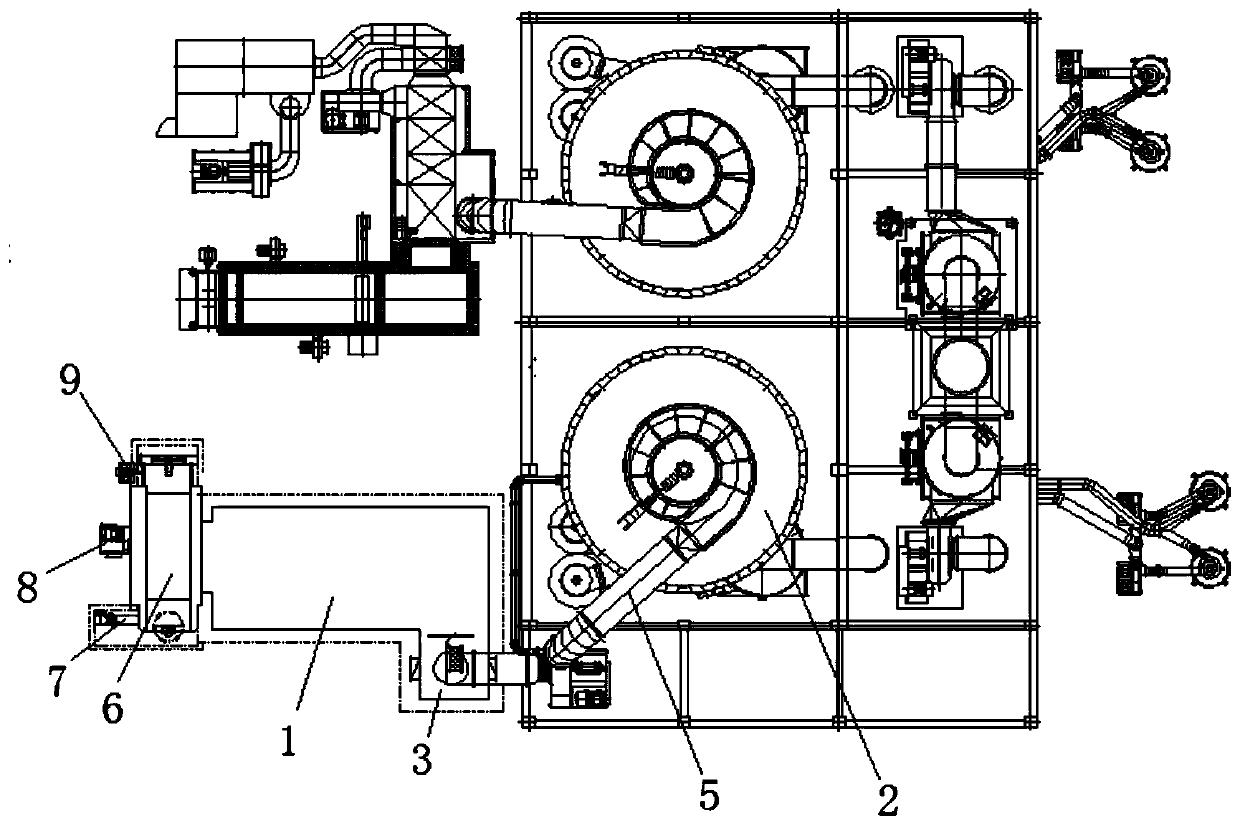

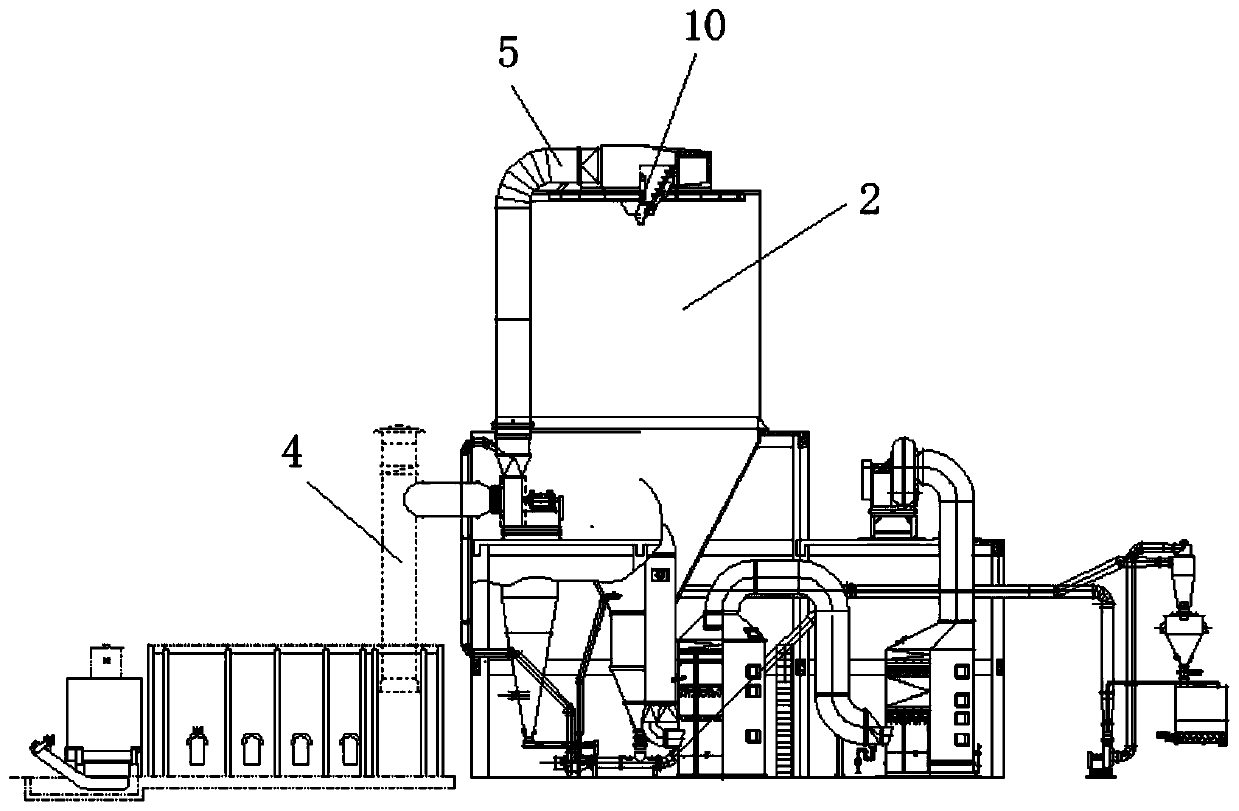

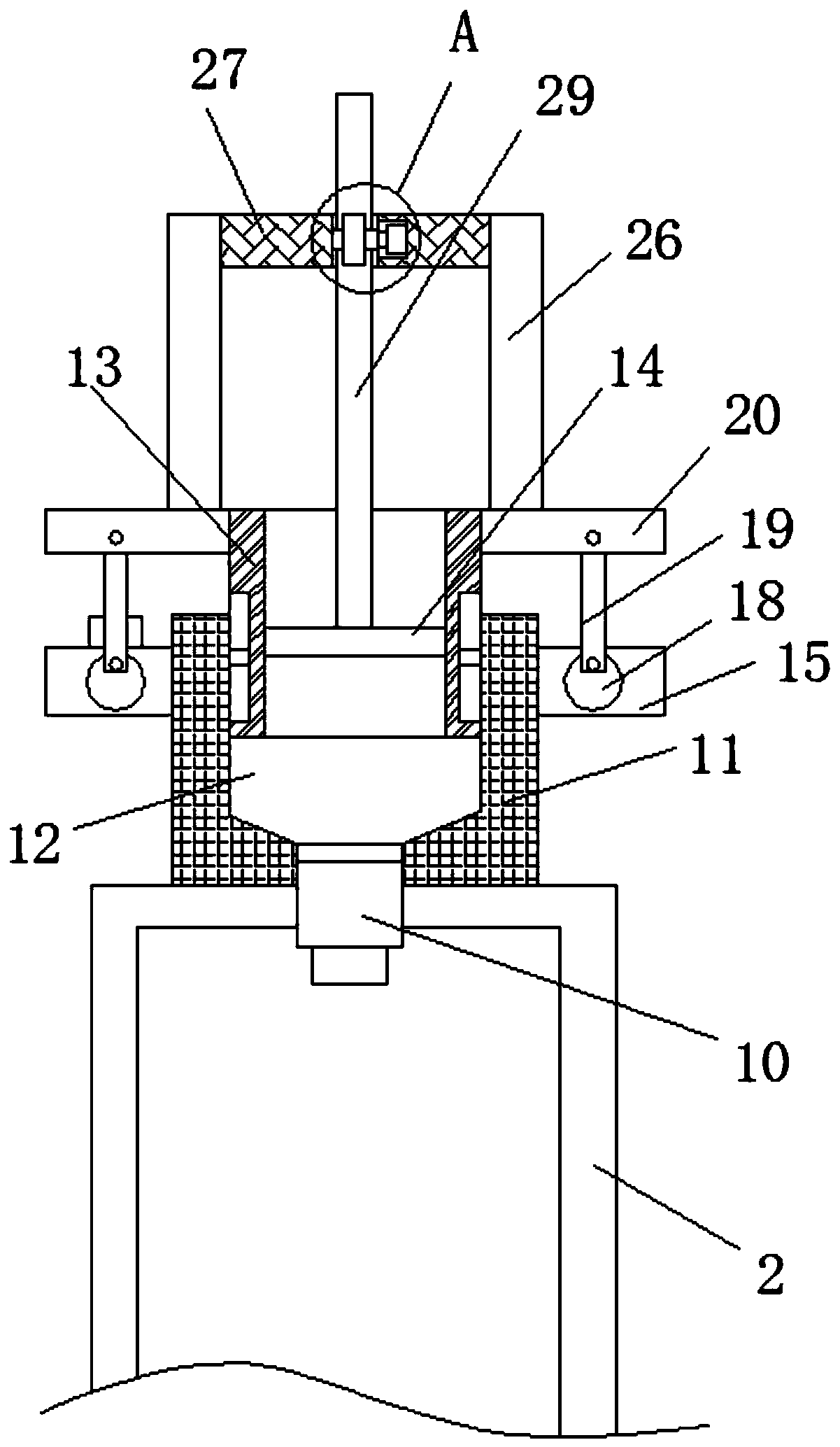

[0024] reference Figure 1-5 In this embodiment, a high-speed centrifugal spray dryer is proposed, which includes a high-temperature purification chamber 1 and a drying tower 2 located on one side of the high-temperature purification chamber 1, and a mixing chamber 3 is provided on one side of the high-temperature purification chamber 1. 3 is fixedly installed at the top of the air supply tube 4, the top of the air supply tube 4 is fixedly connected to one end of the spiral tube 5, the other end of the spiral tube 5 is located in the drying tower 2, and the high temperature purification chamber 1 is located on the side away from the drying tower 2. There is a coal-fired machine 6, and the side of the coal-fired machine 6 away from the high-temperature purification chamber 1 is provided with a slag tapper 7, a combustion fan 8 and a grate reducer 9. The combustion fan 8 is located between the slag tapper 7 and the grate reducer 9 Between, the top inner wall of the drying tower 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com