Zinc-calcium mineralized composite filtering core for adolescent growth, and preparation method thereof

A composite filter element and teenagers' technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems that teenagers pay less attention to, and achieve the effects of no heavy metal exceeding the standard, simple process, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

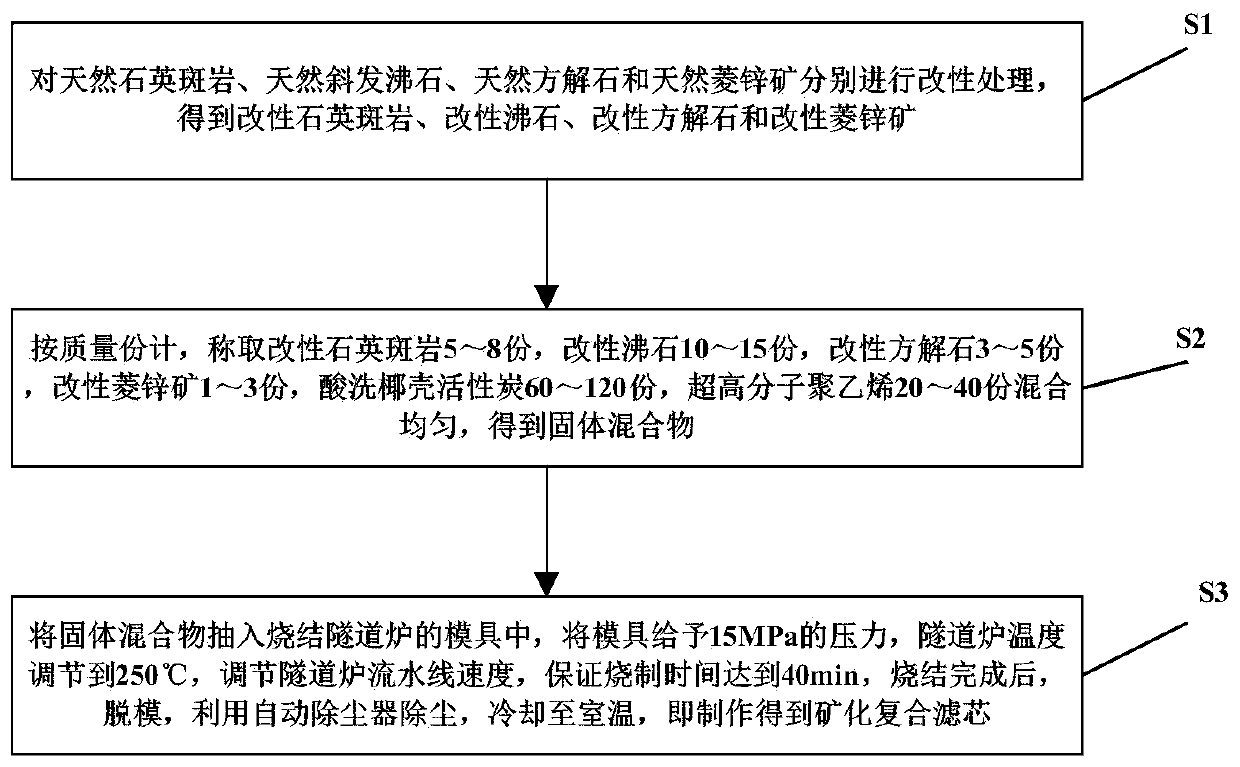

Method used

Image

Examples

preparation example Construction

[0024] The preparation process of the modified zeolite is as follows: crush the natural clinoptilolite, pass through 6 mesh and 18 mesh sieves, then immerse the clinoptilolite particles in 0.2mol / L phosphoric acid solution for 3 hours, and then clean them with deionized water in ultrasonic wave. Washing in the instrument for 2 hours, then impregnating the acid-modified zeolite in the alkaline solution prepared by magnesite rock with a pH of 11 for 2.5 hours, and then washing in the ultrasonic cleaner with deionized water for 2 hours, and then in Roasting at 400°C-500°C for 2 hours, cooling, grinding, and passing through 100 mesh and 325 mesh sieves, the modified zeolite is obtained; the preparation process of the alkaline solution prepared by magnesite rocks is: magnesite rocks are dissolved In the water, bicarbonate ions will dissolve, and when the pH value is detected to be 11, the magnesite rock is taken out, and the solution left is the alkaline solution prepared by the mag...

Embodiment 1

[0035] Weigh 5g of modified quartz porphyry, 10g of modified zeolite, 3g of modified calcite, 1g of modified smithsonite, 60g of acid-washed coconut shell activated carbon with a particle size of 80-325 mesh, and ultra-high molecular weight with a particle size of 80-325 mesh Mix 20g of polyethylene evenly, pump it into the mold of the sintering tunnel furnace, give the mold a pressure of 15MPa, adjust the temperature of the tunnel furnace to 250°C, adjust the speed of the tunnel furnace assembly line to ensure that the firing time reaches 40min, and finally remove the sintered carbon rod from the mold , and use an automatic dust collector to remove dust, cool to room temperature, and obtain a 7-inch, zinc-calcium mineralized composite filter element at a flow rate of 1.0L / min.

[0036] In Example 1, every 1 g is one serving.

Embodiment 2

[0038]Take by weighing 8g of the above-mentioned modified quartz porphyry, 15g of modified zeolite, 5g of modified calcite, 3g of modified smithsonite, 120g of acid-washed coconut shell activated carbon, and 40g of ultra-high molecular polyethylene, mix evenly, and pump them into the mold of the sintering tunnel furnace In the process, the mold is given a pressure of 15MPa, the temperature of the tunnel furnace is adjusted to 250°C, and the speed of the tunnel furnace line is adjusted to ensure that the firing time reaches 40 minutes. Finally, the sintered carbon rod is demoulded, and the dust is removed by an automatic dust collector, and cooled to room temperature to obtain 8-inch zinc and calcium mineralization composite filter element under the condition of flow rate 1.5L / min.

[0039] In Example 2, every 1 g is one serving.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com