Preparation method of cerium-doped NH2-UiO-66/indium zinc sulfide composite visible-light-induced photocatalysts

An nh2-uio-66, indium zinc sulfide technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low hydrothermal stability, Limit the application and other problems, to achieve the effect of improving the photocatalytic degradation activity, high reproducibility, mild and controllable preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

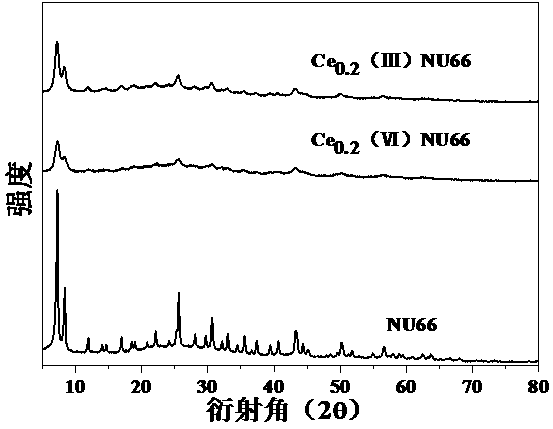

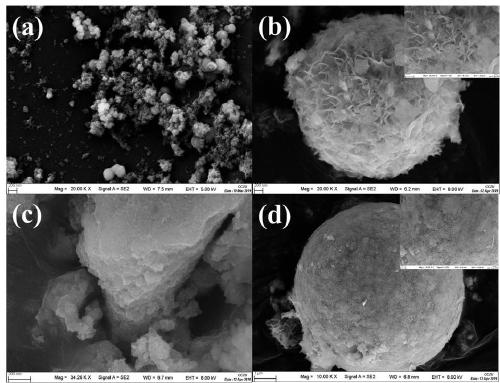

[0021] (1) Ce (Ⅳ) 0.1 Preparation of -NU66: Dissolve 0.2332 g of zirconium chloride, 0.4932 g of cerium ammonium nitrate and 0.1812 g of 2-aminoterephthalic acid in 50 mL of N,N-dimethylformamide. Transfer to a polytetrafluoroethylene liner, 120 °C hydrothermal reaction for 24 h, after the hydrothermal kettle is cooled to room temperature, the product is centrifugally washed with N,N-dimethylformamide and anhydrous methanol , to get Ce(Ⅳ) 0.1 -NU66.

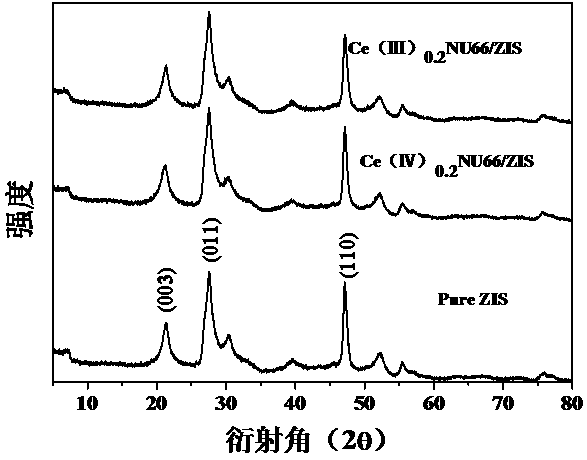

[0022] (2) Ce (Ⅳ) 0.1 - Preparation of NU66 / ZIS composite visible light catalyst: Dissolve 0.137 g zinc chloride and 0.588 g indium trichloride in water, add 0.301 g thioacetamide, stir magnetically to obtain indium zinc sulfide precursor solution, add 0.0301 g Ce (Ⅳ ) 0.1 -NU66 powder, after ultrasonication for a period of time, transfer the suspension to 100 mL polytetrafluoroethylene lining, 120 °C hydrothermal reaction for 24 h, after the hydrothermal kettle is cooled to room temperature, use water and ethanol as detergen...

Embodiment 2

[0024] (1) Ce (Ⅲ) 0.1 Preparation of -NU66: Dissolve 0.2332 g of zirconium chloride, 0.0434 g of cerium (Ⅲ) nitrate and 0.1812 g of 2-aminoterephthalic acid in 50 mL of N,N-dimethylformamide. The solution was transferred to a 100mL polytetrafluoroethylene liner, and subjected to hydrothermal reaction at 120 °C for 24 h. After the hydrothermal kettle was cooled to room temperature, N,N-dimethylformamide, anhydrous methanol and acetone were used as detergents in sequence. , the product was centrifuged and washed to give Ce(Ⅲ) 0.1 -NU66

[0025] (2) Ce(Ⅲ) 0.1 - Preparation of NU66 / ZIS composite visible light catalyst: Dissolve 0.137 g of zinc chloride and 0.588 g of indium trichloride in water, add 0.301 g of thioacetamide, stir magnetically to obtain an indium zinc sulfide precursor, add 0.0301 g of Ce (Ⅲ ) 0.1 -NU66 powder, after ultrasonication for a period of time, transfer the suspension to 100 mL polytetrafluoroethylene lining, 120 °C hydrothermal reaction for 24 h, aft...

Embodiment 3

[0027] (1) Ce (Ⅳ) 0.2 Preparation of -NU66: Dissolve 0.2332 g of zirconium chloride, 0.0110 g of cerium ammonium nitrate and 0.1812 g of 2-aminoterephthalic acid in 50 mL of N,N-dimethylformamide. Transfer to a polytetrafluoroethylene liner, 120 °C hydrothermal reaction for 24 h, after the hydrothermal kettle is cooled to room temperature, the product is centrifugally washed with N,N-dimethylformamide and anhydrous methanol , to get Ce(Ⅳ) 0.2 -NU66.

[0028] (2) Ce (Ⅳ) 0.2 - Preparation of NU66 / ZIS composite visible light catalyst: Dissolve 0.137 g zinc chloride and 0.588 g indium trichloride in water, add 0.301 g thioacetamide, stir magnetically to obtain indium zinc sulfide precursor solution, add 0.0301 g Ce (Ⅳ ) 0.2 -NU66 powder, after ultrasonication for a period of time, transfer the suspension to 100 mL polytetrafluoroethylene lining, 120 °C hydrothermal reaction for 24 h, after the hydrothermal kettle is cooled to room temperature, use water and ethanol as detergen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com