Lithium ion battery charged pretreatment equipment and method

A lithium-ion battery, pretreatment technology, applied in secondary batteries, battery recycling, grain processing, etc., can solve problems such as endangering the personal safety of operators, harmful substances entering the environment, and electrolyte volatilization and leakage. The effect of preventing personal safety and fast drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

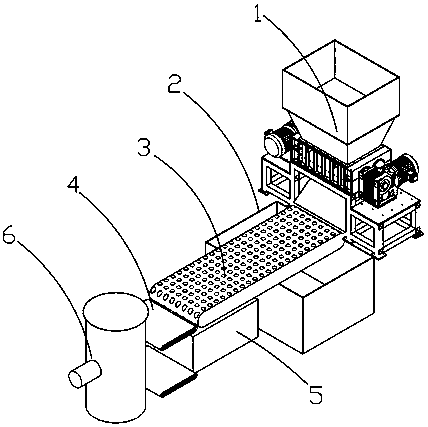

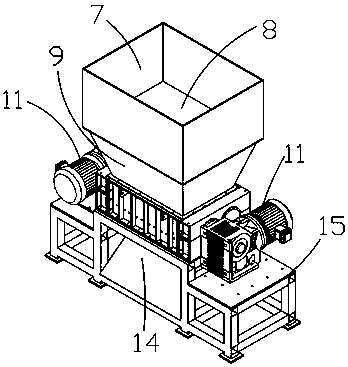

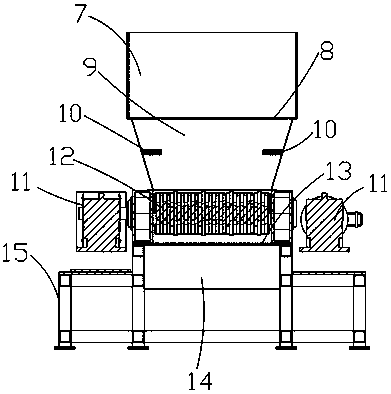

[0031] Such as Figure 1-Figure 3 As shown, a lithium-ion battery charged pretreatment device described in this embodiment includes a wet crusher 1, a powder recovery tank 2, a screen conveyor belt 3, a material collection conveyor belt 4, a belt vacuum filter press 5 and a boiling Dryer 6; the wet crusher is set on a horizontal fixed table, the discharge port 14 of the wet crusher is connected to the feed end of the screen conveyor belt, and the powder recovery tank is arranged on the screen conveyor belt and the discharge port of the wet crusher Below, the opening of the powder recovery tank is upward, which is used to collect the cleaning solution and positive and negative electrode powder falling from the screen conveyor belt and the outlet of the wet crusher; the belt vacuum filter is set on the screen conveyor belt Below, the belt-type vacuum filter is a sealed structure, which is connected with the powder recovery tank, and the feed port of the belt-type vacuum filter i...

Embodiment 2

[0039] A method for processing a lithium-ion battery by the lithium-ion battery charging pretreatment device of embodiment 1, comprising the following steps:

[0040] 1. The wet crusher is in the initial state, that is, the material baffle, solution switch valve, and solution baffle are all in the closed state; the transmission mechanism intermittently transports the charged lithium-ion battery material to the material storage box, and opens the solution switch valve to make lithium The ion battery cleaning solution enters the wet crushing chamber, and when it reaches a certain capacity, the solution switch valve is closed;

[0041] 2. Start the motor, the two shredding shafts start to rotate in opposite directions, and the material baffle is gradually opened under the drive of the cylinder, so that the lithium-ion battery enters the wet crushing chamber, and the material baffle is reset; Under the action of shearing, it is broken into flakes, and part of the black powder of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com