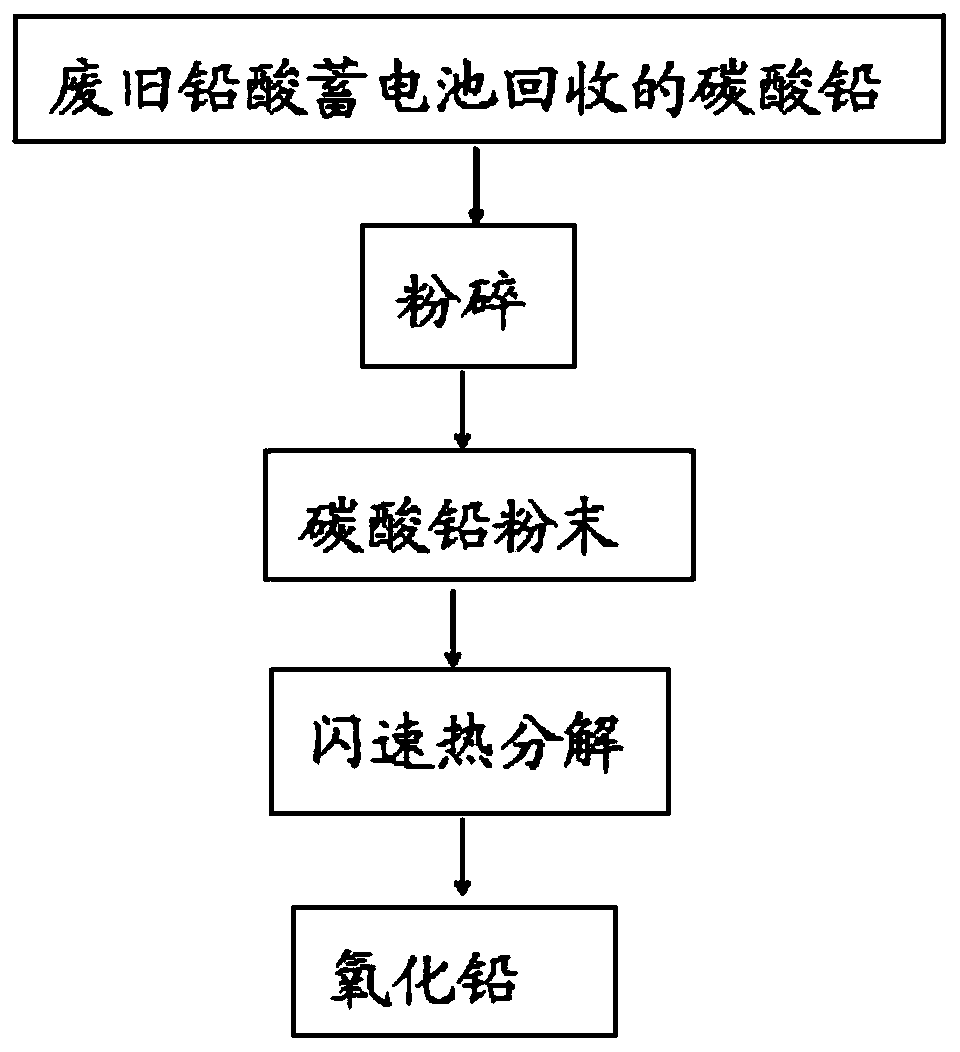

Method for recovering lead oxide from waste lead-acid storage battery

A technology of lead-acid battery and recovery method, which is applied in the direction of lead monoxide and lead oxide, which can solve the problems of long reaction time, complicated process, and low product purity, and achieve short reaction time, low energy consumption, and short process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

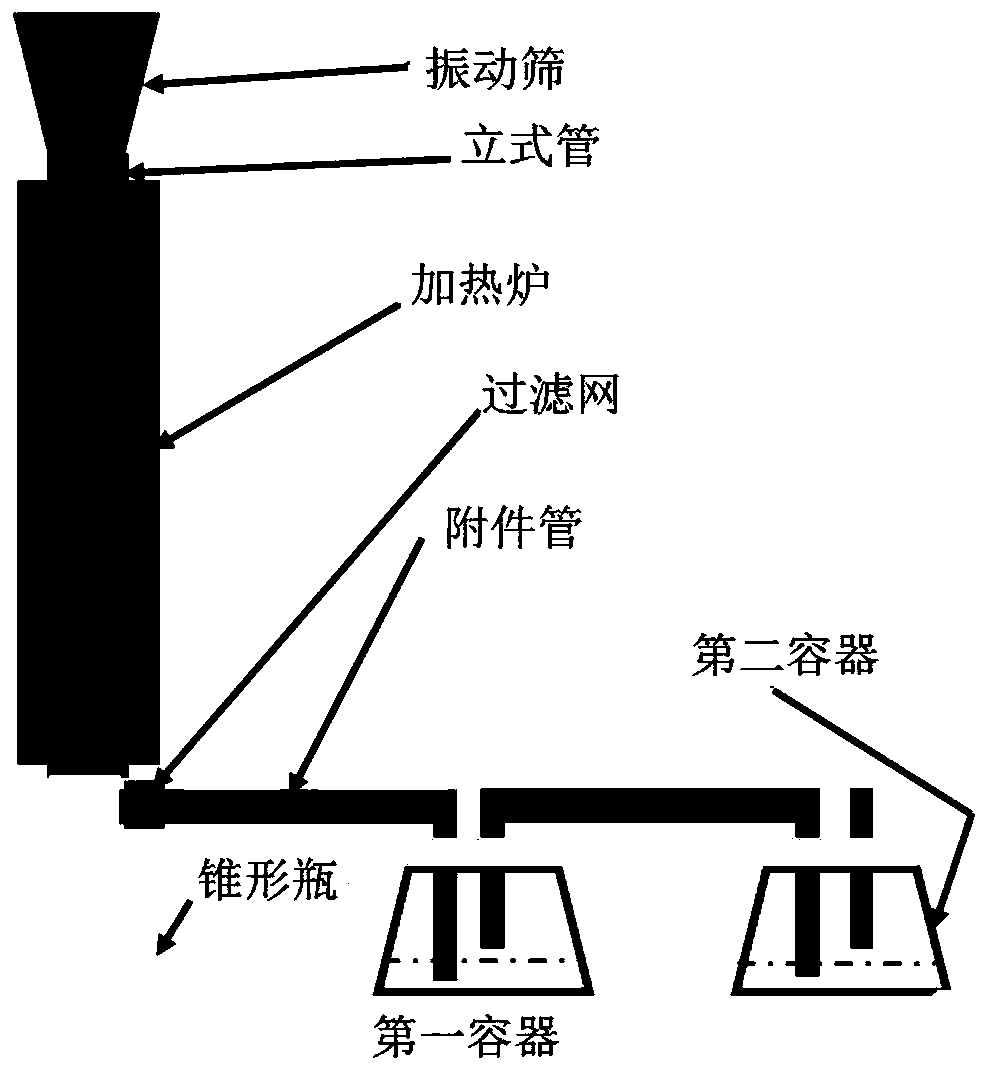

Embodiment 1

[0038] 20g of PbCO that has been sieved through a 400-mesh sieve will be reclaimed from waste lead-acid batteries 3 Put the powder into the vibrating sieve; then heat the furnace to 400°C and keep the furnace temperature stable; then start feeding, the material will fall from the top of the vertical tube and react in the vertical tube. After the flash thermal decomposition reaction is complete, remove the product. Finally, XRD analysis is carried out to determine the product phase. The first container is filled with water to absorb the tiny dust particles produced by flash thermal decomposition, and the second container is filled with sodium hydroxide solution to absorb carbon dioxide produced by flash thermal decomposition. . The results show that the product is all red α-PbO, such as image 3 and Figure 4 shown, where image 3 It is the physical photo of α-PbO, Figure 4It is the XRD pattern of α-PbO. After detection, the quality of the obtained lead oxide is 19.8g, an...

Embodiment 2

[0040] 20g of PbCO that has been sieved through a 400-mesh sieve will be reclaimed from waste lead-acid batteries 3 Put the powder into the vibrating sieve; then heat the furnace to 550°C and keep the furnace temperature stable; then start feeding, the material will fall from the top of the vertical tube and react in the vertical tube. After the flash thermal decomposition reaction is complete, remove the product. Finally, XRD analysis is carried out to determine the product phase. The first container is filled with water to absorb the tiny dust particles produced by flash thermal decomposition, and the second container is filled with sodium hydroxide solution to absorb carbon dioxide produced by flash thermal decomposition. . The results show that the product is all yellow β-PbO, such as Figure 5 and Figure 6 shown, where Figure 5 It is the physical photo of β-PbO, Figure 6 It is the XRD spectrum pattern of β-PbO, after detection, the quality of the obtained lead oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com