Preparation method and equipment of novel bio-magnetic suspension filler for water treatment

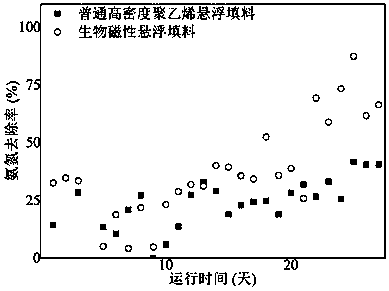

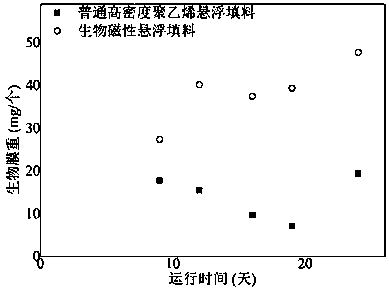

A technology of suspended filler and water treatment, which is applied in special compound water treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Production cost, effect of enhancing microbial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

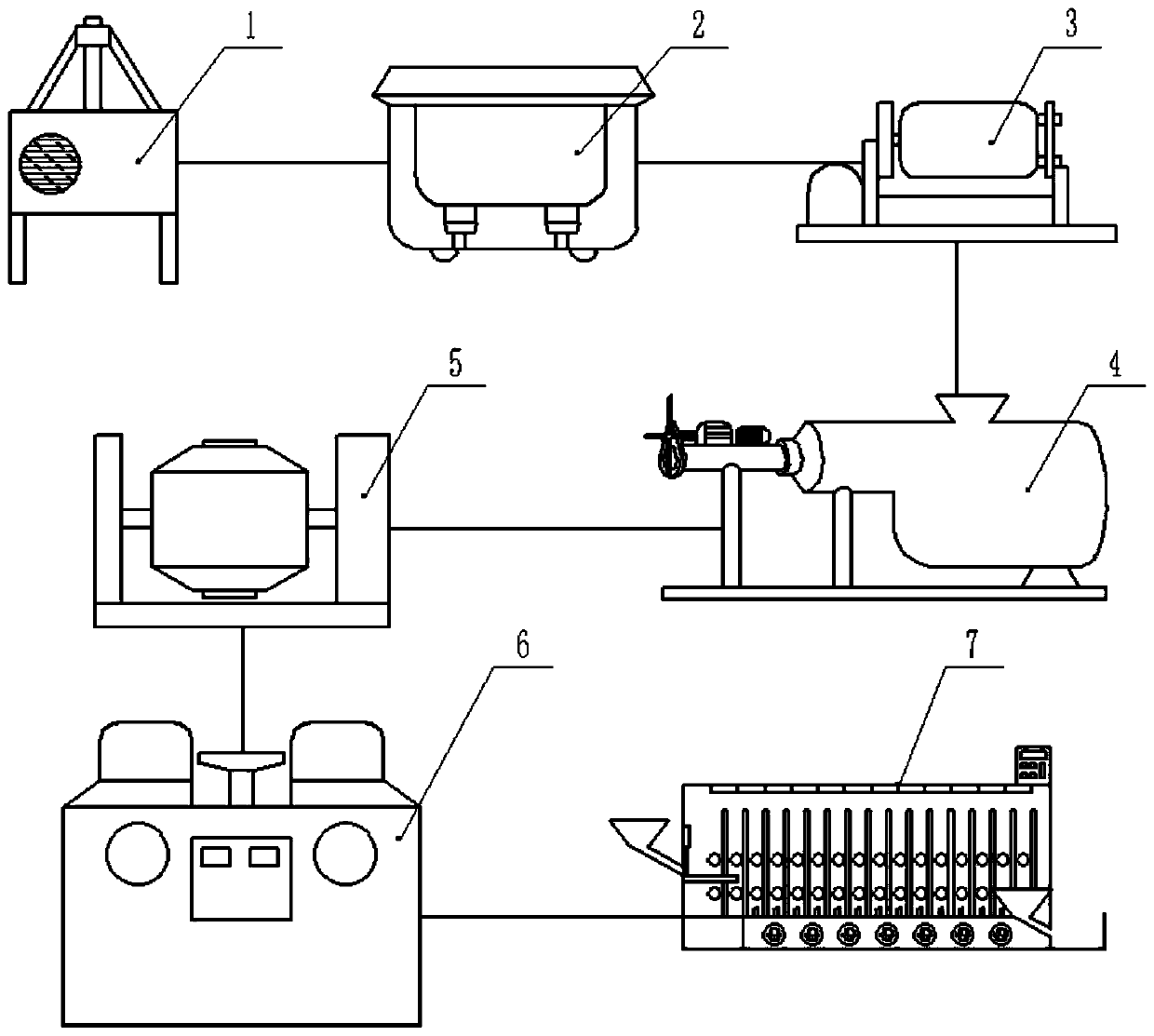

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: preparation novel water treatment biomagnetic suspension filler, comprises the following steps:

[0048] S1: Magnetic powder surface treatment: Soak the magnetic powder with 1mol / L alkaline potassium persulfate solution. The magnetic powder is RuFeB powder. Stir continuously during the soaking process. After soaking for 3 hours, take it out and dry to obtain modified magnetic powder. Put the modified magnetic powder in Stir in an agitator, dilute the titanate coupling agent with white mineral oil at a mass ratio of 1:1, atomize and spray the diluted titanate coupling agent into the agitator, and continue stirring for 20 minutes to obtain Activated magnetic powder;

[0049] S2: Modification of the carrier material: add the composite emulsifier and phenyltrichlorosilane in the mass ratio of 2:1 into the ultrasonic emulsification device for ultrasonic emulsification for 1 hour to obtain a silicone emulsion, and then mix the silicone emulsion and polyurethane by...

Embodiment 2

[0055] Embodiment 2: the preparation of novel biomagnetic suspension filler for water treatment comprises the following steps:

[0056] S1: Magnetic powder surface treatment: Soak the magnetic powder with 2mol / L alkaline potassium persulfate solution. The magnetic powder is RuFeB powder. Stir continuously during the soaking process. After soaking for 4 hours, take it out and dry to obtain the modified magnetic powder. Put the modified magnetic powder in Stir in an agitator, dilute the titanate coupling agent with white mineral oil at a mass ratio of 1:1, atomize and spray the diluted titanate coupling agent into the agitator, and continue stirring for 25 minutes to obtain Activated magnetic powder;

[0057] S2: Modification of the carrier material: add the composite emulsifier and phenyltrichlorosilane into the ultrasonic emulsification device at a mass ratio of 2.3:1 for ultrasonic emulsification for 1.5 hours to obtain a silicone emulsion, and then combine the silicone emuls...

Embodiment 3

[0063] Embodiment 3: the preparation of novel biomagnetic suspension filler for water treatment comprises the following steps:

[0064] S1: Surface treatment of magnetic powder: Soak the magnetic powder with 3mol / L alkaline potassium persulfate solution. The magnetic powder is RuFeB powder. Stir continuously during the soaking process. After soaking for 5 hours, take it out and dry to obtain the modified magnetic powder. Put the modified magnetic powder in Stir in an agitator, dilute the titanate coupling agent with white mineral oil at a mass ratio of 1:1, atomize and spray the diluted titanate coupling agent into the agitator, and continue stirring for 30 minutes to obtain Activated magnetic powder;

[0065] S2: Modification of the carrier material: add the composite emulsifier and phenyltrichlorosilane into the ultrasonic emulsification device at a mass ratio of 2.5:1 for ultrasonic emulsification for 2 hours to obtain a silicone emulsion, and then combine the silicone emul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com