Silicon dioxide/titanium dioxide double-layer antireflection film and preparation method thereof

An anti-reflection film and double-layer technology, applied in the field of solar cells, can solve the problems of low light transmittance of the anti-reflection film and obvious dependence on the light transmittance of the film layer, and achieve a large change range, small light transmittance fluctuation, and a change range. no effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

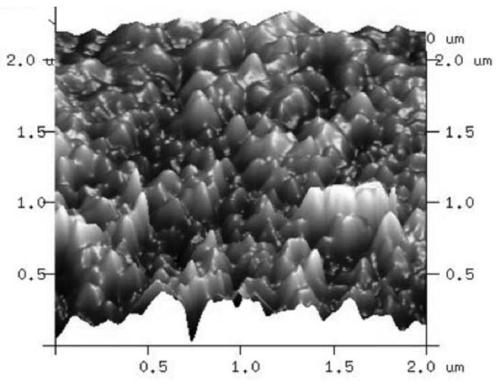

[0027] Embodiment 1 sol and SiO 2 Granule preparation

[0028] (1) SiO 2 Sol preparation

[0029] SiO 2 Preparation of acid sol: First take a 250ml beaker, then weigh 23.365g TEOS, 98.000g EtOH, 8.075g deionized water, 0.327g HCl, stir on a magnetic stirrer for 3h, then seal with plastic wrap, and age in a cool and dry place for 3d . The prepared samples are marked as SiO 2 -a.

[0030] SiO 2 Preparation of alkali sol: First take a 250ml beaker, weigh 18.692g TEOS, 152.204g absolute ethanol, 3.230g deionized water, 2.512g ammonia water, stir on a magnetic stirrer for 3 hours, then seal with plastic wrap, and age in a cool and dry place 3d. The prepared samples are marked as SiO 2-b.

[0031] SiO 2 Preparation of acid-base sol: The sol obtained by catalyzing the above acid and base is mixed according to the mass ratio of acid to base at 1:2, and the prepared sample is marked as SiO 2 -a1b2. According to the above acid-base catalysis, the sol is obtained by mixing t...

Embodiment 2

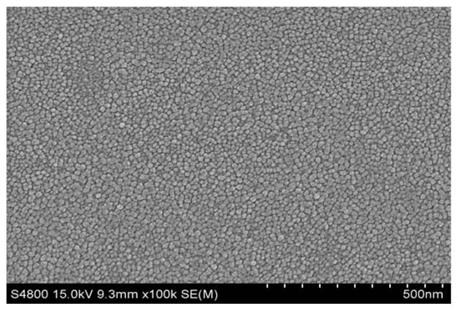

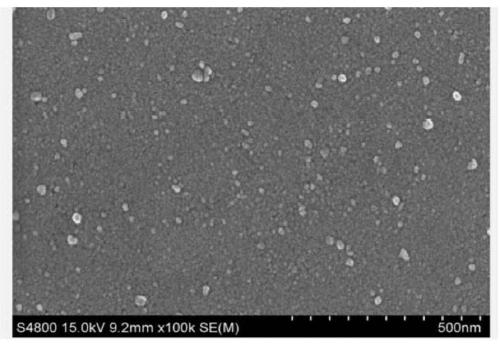

[0036] The preparation of embodiment 2 anti-reflection film

[0037] (1) Cleaning of glass substrate

[0038] Rinse the glass substrate with tap water first, then rinse it with deionized water, then soak it in NaOH with a mass fraction of 20% for 20min, then rinse it with deionized water, and then put it into 15% HNO 3 Soak in water for 20 minutes, rinse with deionized water, then ultrasonically clean in deionized water for 5 minutes, then ultrasonically clean in absolute ethanol for 5 minutes, dry in a constant temperature drying oven at 80°C for 2 hours, take it out and store it for later use.

[0039] (2) Preparation of double-layer anti-reflection film

[0040] Turn on the power supply of the KW-4A glue homogenizer, adjust the low speed to 500r / min for 18s, adjust the high speed to 2000r / min for 30s, and then put the aged SiO 2 Take out the sol, use a plastic dropper to take 2 to 3 drops, and drop it into the glass substrate that has been placed on the glue homogenizer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com