High-performance and low-expansion ceramic product and preparation method thereof

A low-expansion, high-performance technology, applied in the field of ceramic materials, can solve the problems of few ceramic products, poor glaze adhesion, easy cracking of the glaze layer, etc. The effect of shock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

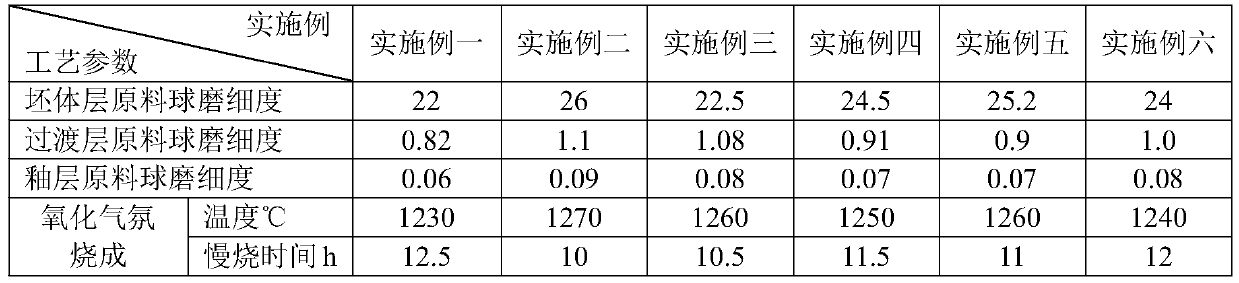

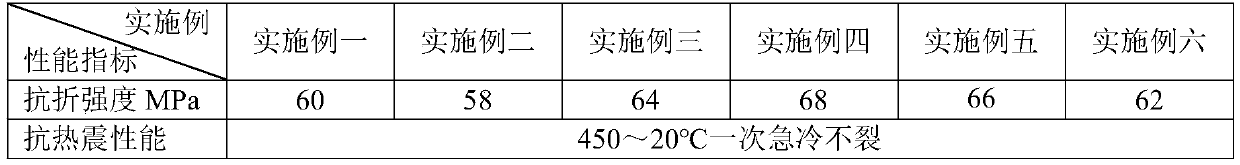

[0026] An embodiment of a high-performance low-expansion ceramic product of the present invention includes a body layer and a glaze layer, and there is a transition layer between the body layer and the glaze layer; its raw material composition is shown in Table 1.

[0027] The raw material composition of table 1 embodiment of the present invention high-performance low-expansion ceramic product

[0028]

[0029] Wherein, the particle size of the fused silica powder is 0.1-0.2 mm.

[0030] The preparation method of the above-described high-performance low-expansion ceramic product of the present invention is as follows:

[0031] (1) Preparation of green body layer mud

[0032] The components of the raw materials of the green body layer are mixed by ball milling until the fineness is 22-26% after the sieve of 250 mesh, and then dewatered by pressure filtration, vacuum mud refining, molding and drying to obtain the mud of the green body layer;

[0033] (2) Preparation of tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com