Method of preparing N-acetylneuraminic acid with immobilized double enzymes

A technology for acetylneuraminic acid and neuraminic acid aldolase, which is applied in the field of preparing N-acetylneuraminic acid, can solve the problems of low conversion rate, stable enzyme without immobilized enzyme, low efficiency, etc. The effect of increasing conversion rate and stable conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

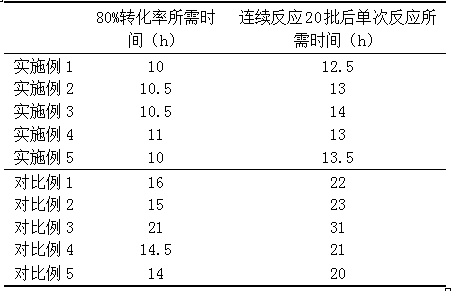

Examples

Embodiment 1

[0019] A method for preparing N-acetylneuraminic acid by immobilizing double enzymes, the immobilization process of immobilized N-acetylglucosamine-2-epimerase and immobilized N-acetylneuraminic acid aldolase is as follows: The total enzyme activity ratio of N-acetylglucosamine-2-epimerase enzyme solution numbered E.C.5.1.3.8 and N-acetylneuraminic acid aldolase enzyme solution numbered E.C.4.1.3.3 is 1:2 Mix, after cooling in an ice-water bath, add ammonium sulfate with a mass fraction of 75% while stirring to form a precipitate, collect the precipitate after centrifugation, then add a glutaraldehyde solution with a mass fraction of 25% while stirring, and react at 15°C for 3 hours Cross-linking and immobilization to form immobilized N-acetylglucosamine-2-epimerase and immobilized N-acetylneuraminic acid aldolase.

[0020] The process of preparing N-acetylneuraminic acid includes the following steps: at a pH of 7 and a temperature of 30°C, N-acetylglucosamine and sodium pyruv...

Embodiment 2

[0022] A method for preparing N-acetylneuraminic acid by immobilizing double enzymes, the immobilization process of immobilized N-acetylglucosamine-2-epimerase and immobilized N-acetylneuraminic acid aldolase is as follows: N-acetylglucosamine-2-epimerase enzyme solution and N-acetylneuraminic acid aldolase enzyme solution are mixed according to the total enzyme activity ratio of 1:3. After cooling in an ice-water bath, add mass fraction while stirring. 50% ammonium sulfate forms a precipitate, centrifuges to collect the precipitate, then adds a glutaraldehyde solution with a mass fraction of 25%, and reacts at 18°C for 3 hours for cross-linking and fixation. When cross-linking and fixing, the glutaraldehyde solution in the enzyme solution The mass fraction was maintained at 0.2%, and immobilized N-acetylglucosamine-2-epimerase and immobilized N-acetylneuraminic acid aldolase were formed.

[0023] The process of preparing N-acetylneuraminic acid includes the following steps:...

Embodiment 3

[0025] A method for preparing N-acetylneuraminic acid by immobilizing double enzymes, the immobilization process of immobilized N-acetylglucosamine-2-epimerase and immobilized N-acetylneuraminic acid aldolase is as follows: N-acetylglucosamine-2-epimerase enzyme solution and N-acetylneuraminic acid aldolase enzyme solution are mixed according to the total enzyme activity ratio of 1:4, after cooling in an ice-water bath, add mass fraction while stirring 60% ammonium sulfate forms a precipitate, centrifuges to collect the precipitate, then adds its own glutaraldehyde solution with a mass fraction of 25%, and reacts at 18°C for 3 hours for cross-linking and fixation. When cross-linking and fixing, the glutaraldehyde solution in the enzyme solution The mass fraction was maintained at 0.5%, forming immobilized N-acetylglucosamine-2-epimerase and immobilized N-acetylneuraminic acid aldolase.

[0026] The process of preparing N-acetylneuraminic acid includes the following steps: at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com