Preparation method and application of polyaniline nanowire array/three-dimensional graphene

A nanowire array and graphene technology, applied in the field of materials, can solve the problem of low specific capacitance, achieve excellent mechanical properties, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

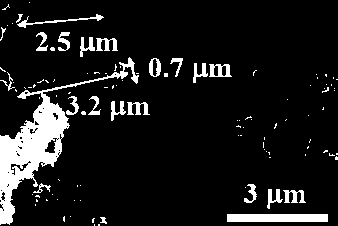

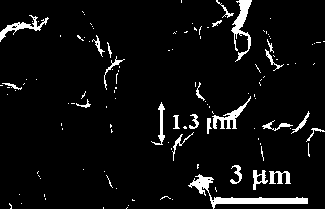

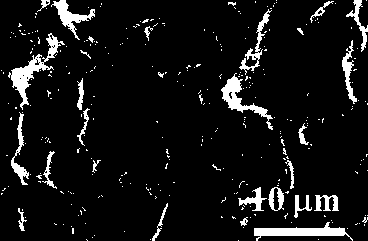

Image

Examples

Embodiment 1

[0028] The preparation method of polyaniline nanowire array / three-dimensional graphene comprises the following steps:

[0029] Step 1: Fill a circular ceramic mold (2cm in diameter and 1cm in height) with 1.0g of nickel nanowires and place it in the center of a high-temperature tube furnace, and then place it in the H 2 Heating to 900~1100℃ under the airflow of / Ar, and annealing for 10~20min to obtain a three-dimensional nickel template, and then pass CH 4 After 10 to 20 minutes of air, the sample was placed in H 2 Cool to room temperature at a rate of 80-100°C / min under Ar airflow to obtain a three-dimensional nickel sample with graphene deposited on the surface;

[0030] The second step: put the above sample into 3-5mol / L hydrochloric acid to etch the nickel template to obtain three-dimensional graphene;

[0031] Step 3: Soak the three-dimensional graphene prepared above in concentrated nitric acid for 12-24 hours;

[0032] Step 4: Soak the three-dimensional graphene in ...

Embodiment 2

[0034] The preparation method of polyaniline nanowire array / three-dimensional graphene comprises the following steps:

[0035] Step 1: Fill a circular ceramic mold (2cm in diameter and 1cm in height) with 1.0g of nickel nanowires and place it in the center of a high-temperature tube furnace, and then place it in the H 2 Heating to 1000~1100℃ under the airflow of / Ar, and annealing for 15~20min to obtain a three-dimensional nickel template, and then pass CH 4 After 15 to 20 minutes of air, the sample was placed in H 2 Cool to room temperature at a rate of 90-100°C / min under Ar flow to obtain a three-dimensional nickel sample with graphene deposited on the surface;

[0036] The second step: put the above sample into 4-5mol / L hydrochloric acid to etch the nickel template to obtain three-dimensional graphene;

[0037] Step 3: Soak the three-dimensional graphene prepared above in concentrated nitric acid for 16-24 hours;

[0038] Step 4: soak the three-dimensional graphene in 1m...

Embodiment 3

[0040] The preparation method of polyaniline nanowire array / three-dimensional graphene comprises the following steps:

[0041] Step 1: Fill a circular ceramic mold (2cm in diameter and 1cm in height) with 1.0g of nickel nanowires and place it in the center of a high-temperature tube furnace, and then place it in the H 2 Heating to 1050-1100°C under the airflow of / Ar, and annealing for 18-20min to obtain a three-dimensional nickel template, and then pass CH 4 After 18-20min in the air, put the sample in H 2 Cool to room temperature at a rate of 95-100°C / min under Ar flow to obtain a three-dimensional nickel sample with graphene deposited on the surface;

[0042] The second step: put the above sample into 4.5-5mol / L hydrochloric acid to etch the nickel template to obtain three-dimensional graphene;

[0043] Step 3: Soak the three-dimensional graphene prepared above in concentrated nitric acid for 20-24 hours;

[0044] Step 4: soak the three-dimensional graphene in 1mol / L sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com