A kind of al-co-mo nanocrystalline composite material and its preparation method and application

An al-co-mo, composite material technology, applied in the nano field, to achieve the effects of excellent performance, strong process control and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

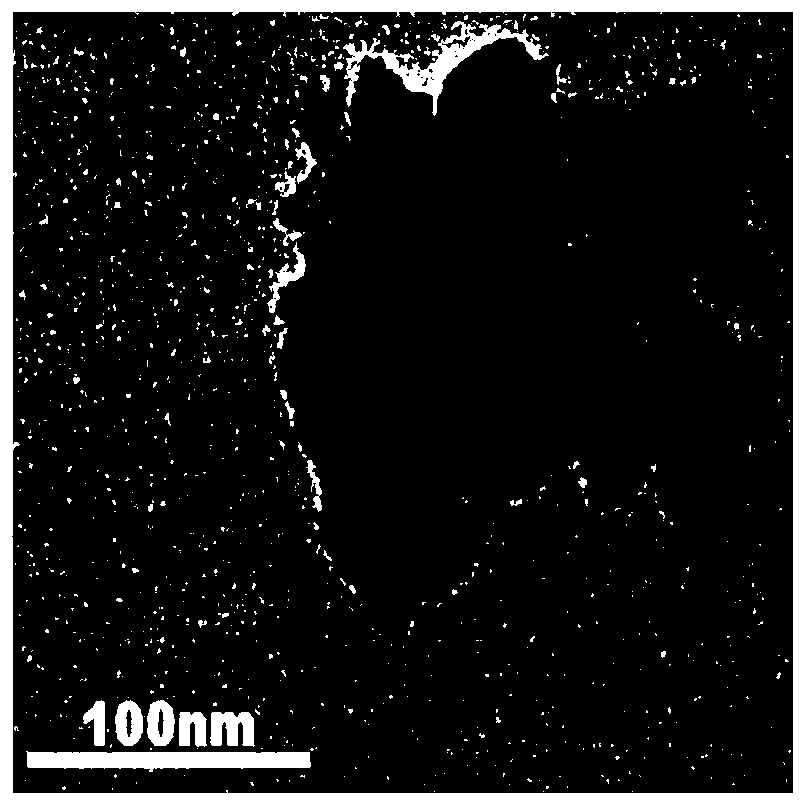

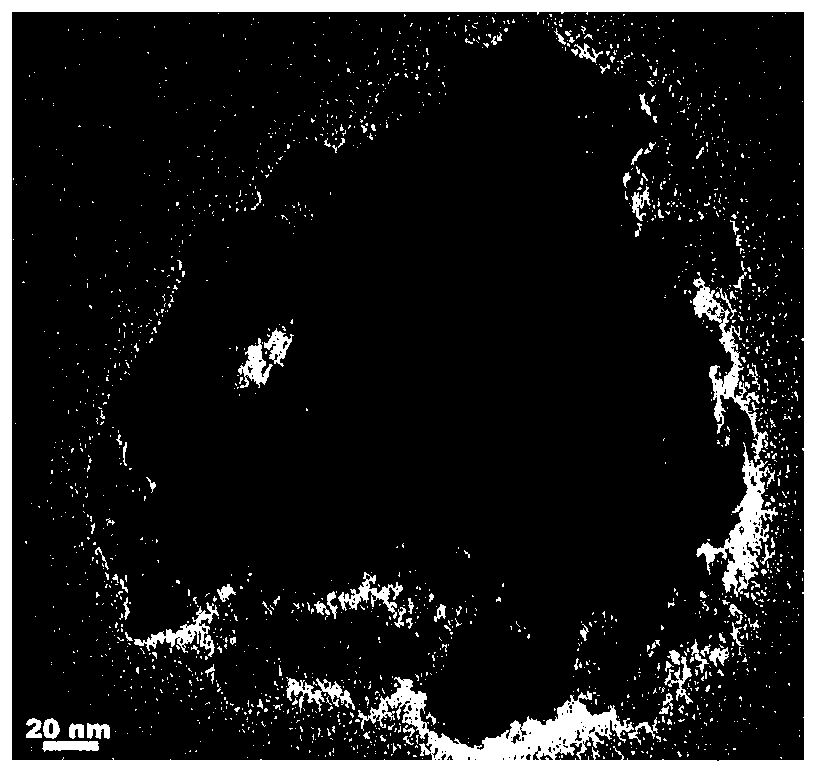

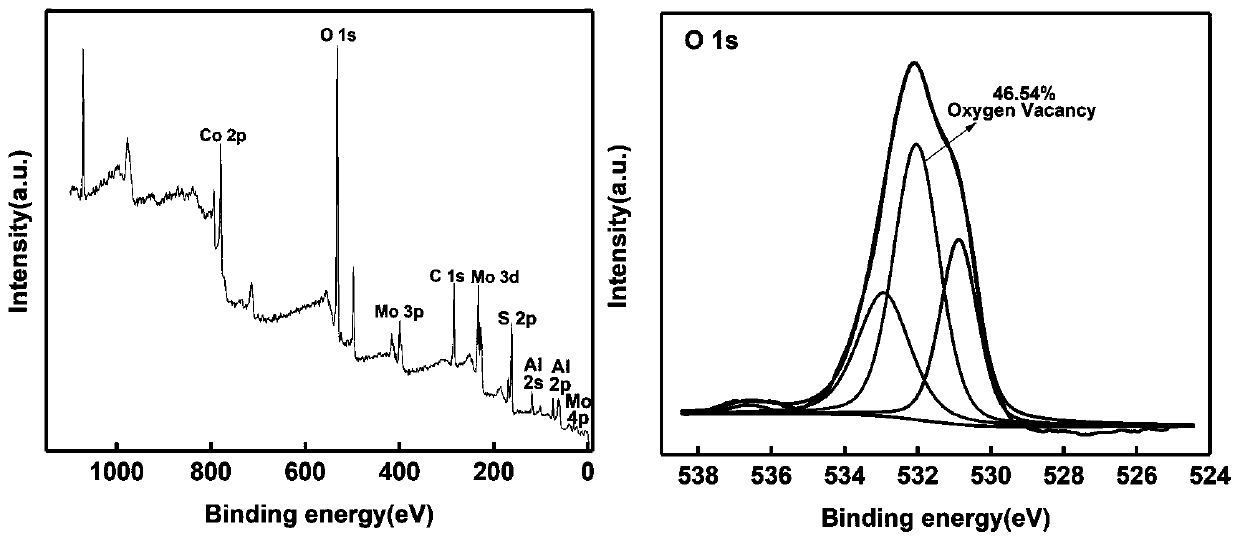

Image

Examples

Embodiment 1

[0031] At room temperature, weigh aluminum isopropoxide (AIP) 1mmol (0.2042g), Co(NO 3 ) 2 . 6H 2 O 3mmol (0.8731g), Na 2 MoO 4 2H 2 O 1mmol (0.2420g), CS (NH 2 ) 2 10mmol (0.7612g) powder, and transfer all the powder to a dry reaction kettle with a capacity of 50 mL, and then use a pipette gun to measure 10mL octadecene, 5mL dodecylamine, and 3mL oleic acid to the reaction kettle , magnetically stirred for 2 h to obtain a solution.

[0032] The reaction kettle was tightened and transferred to an oven, the temperature was gradually raised to 180 °C, and kept at 180 °C for 24 h until the reaction was completed. After the reaction kettle was naturally cooled to room temperature, an appropriate amount of n-heptane and absolute ethanol were added to disperse, and the solid was separated by centrifugation. The solid was washed to obtain a black product, which was used for analysis and characterization after vacuum drying overnight in a vacuum oven.

[0033] Characterized...

Embodiment 2

[0035] In the three-electrode system, the electrochemical properties of the samples were tested by cyclic voltammetry and polarization curve method. The specific process is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com