Laser cladding process molten bath temperature online monitoring device and method

A technology of laser cladding and monitoring device, applied in measurement device, radiation pyrometry, optical radiation measurement, etc., can solve the problem of no fast heating and fast cooling process fixed-point monitoring, inability to measure the highest temperature value of the molten pool, inability to be flexible Design monitoring angle and other issues to achieve the effect of high work stability and reliability, compact structure, and guaranteed cladding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

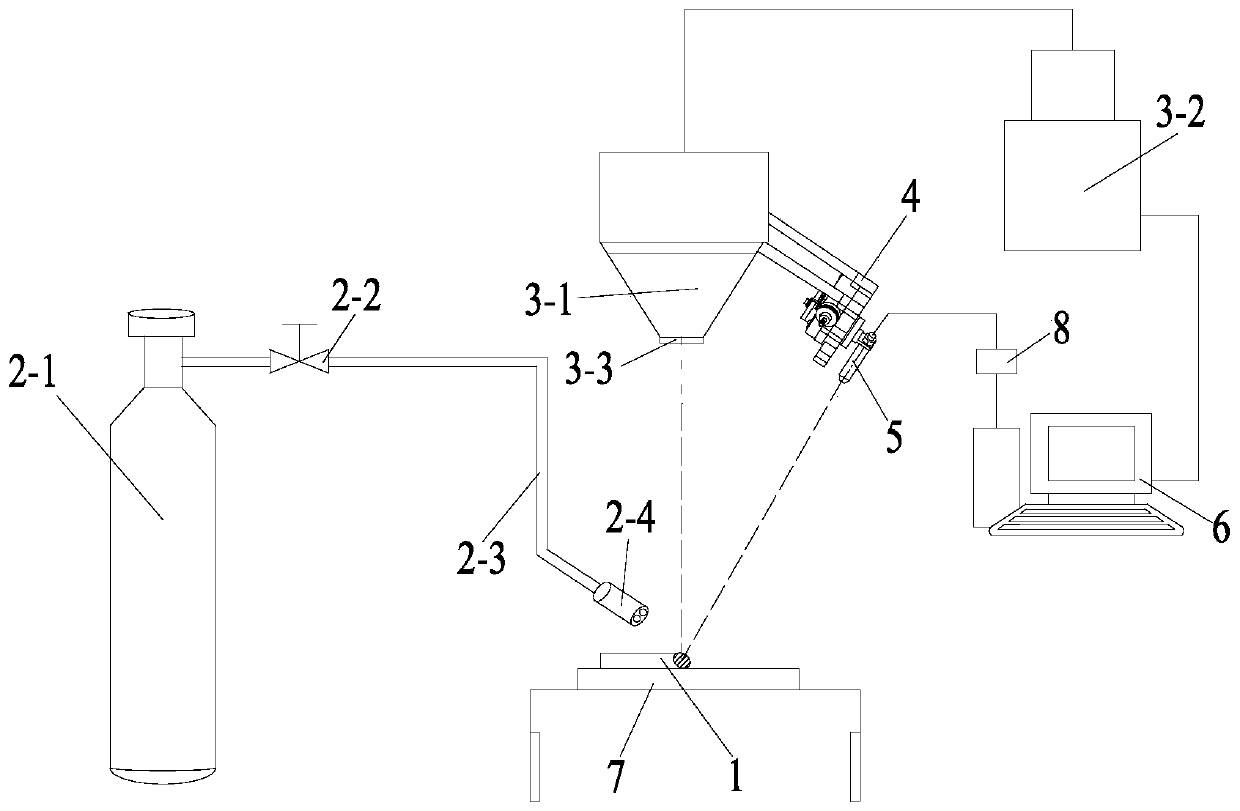

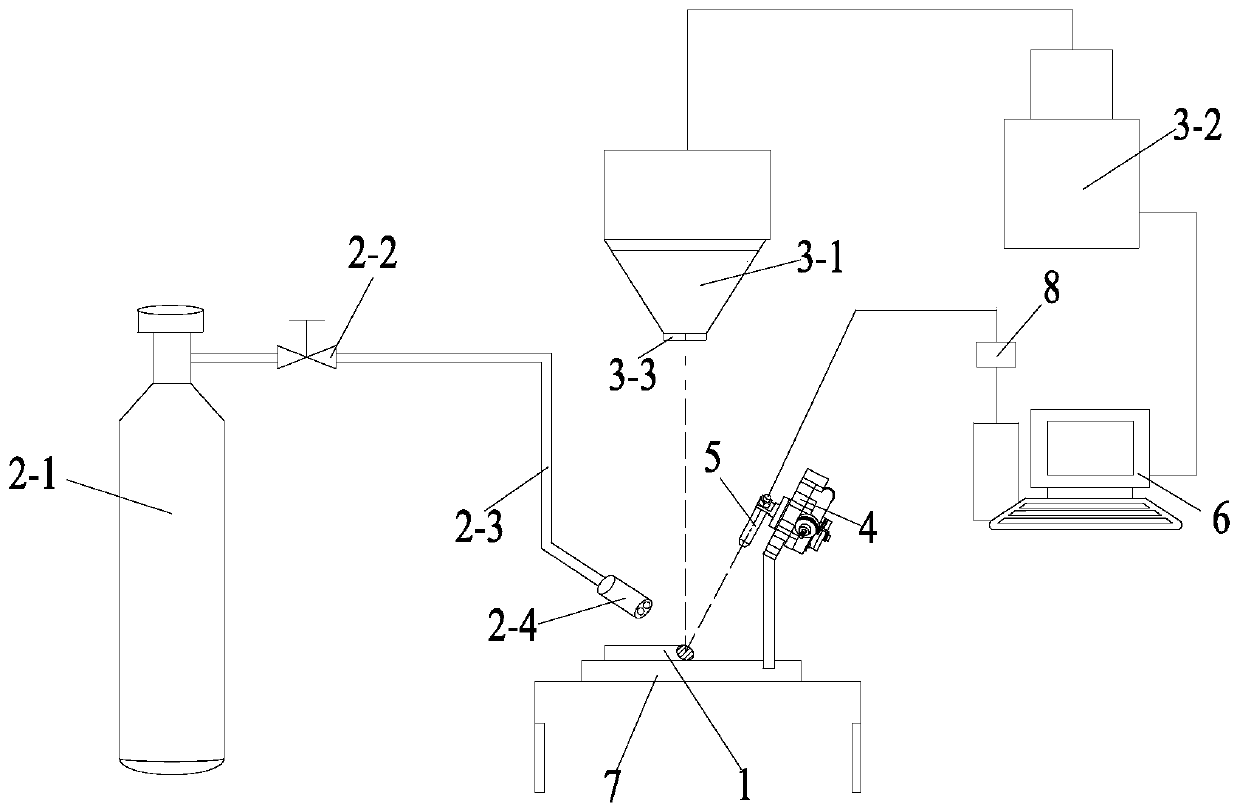

[0062] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 7 As shown, the online monitoring device for molten pool temperature in the laser cladding process of the present invention includes an inert gas protection device, a laser control system, an infrared thermometer fixture 4, an infrared thermometer 5 and a servo workbench 7, and an infrared temperature measuring The data collector 8 that instrument 5 is connected and the computer 6 that joins with data collector 8;

[0063] The inert gas protection device includes an argon cylinder 2-1 and a gas pipeline 2-3 connected to the argon cylinder 2-1, the end of the gas pipeline 2-3 is connected with a nozzle 2 for outputting argon -4, the gas pipeline 2-3 is provided with a flow valve 2-2;

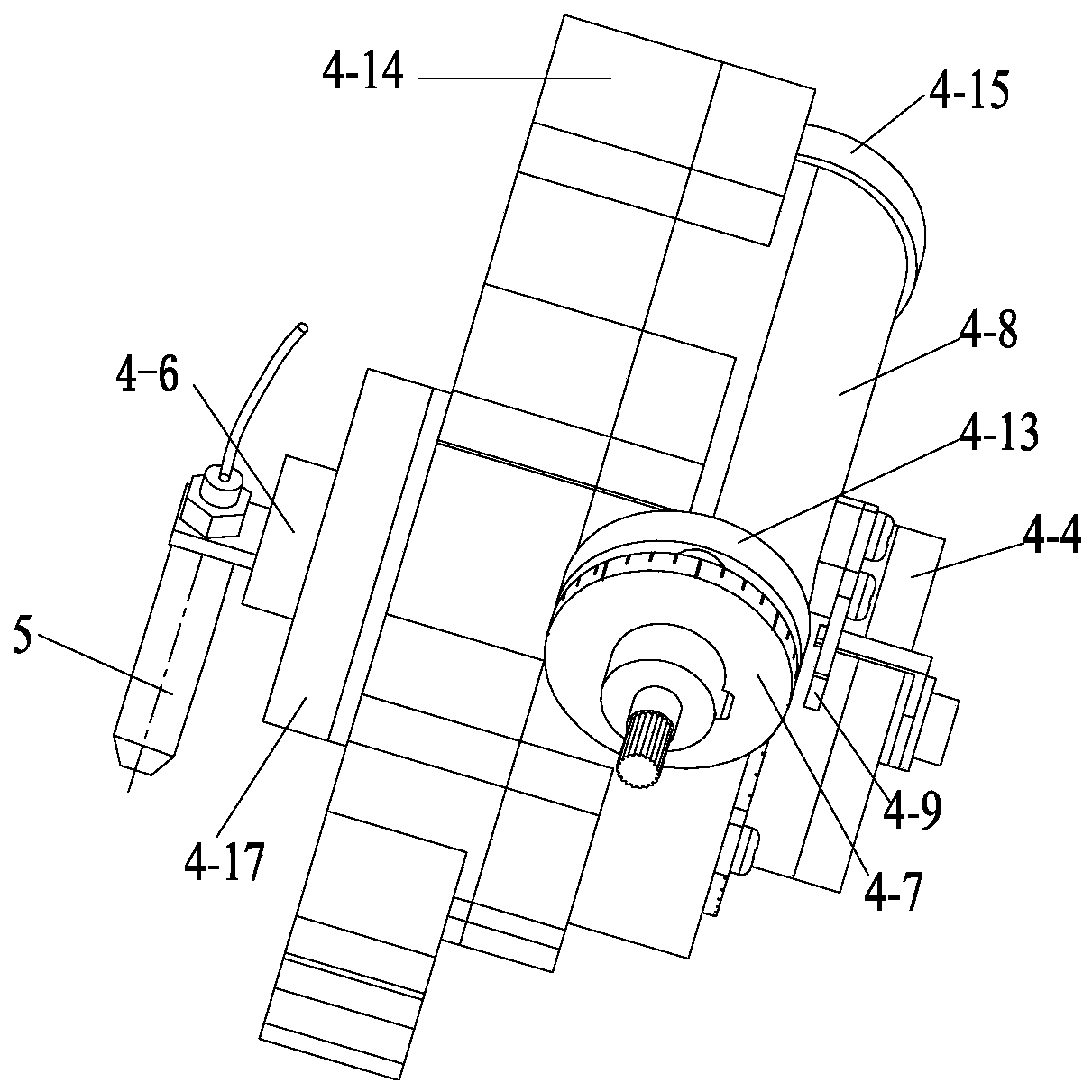

[0064] The infrared thermometer fixture 4 includes a connecting plate 4-14 and a box body 4-8 installed on one side of the connecting plate 4-14, and a transmission shaft 4-6 that runs through the connecting plate 4-14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com