Method for reducing nitrogen oxide emission of wall-hanging stove and fuel gas wall-hanging stove

A gas-fired wall-hung boiler and nitrogen oxide technology, which is applied in the field of natural gas combustion, can solve the problems of limited application scope, high cost, and difficulty in reaching the fourth-level emission of the wall-hung boiler, and achieves the effects of low cost, small structural changes, and reduced emission concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] According to the applicant's literature review and research practice, it is found that the nitrogen oxides generated by the combination of the existing wall-hung boiler structure and the atmospheric burner mainly include the following types:

[0033] 1. A small amount of fuel-type NOx. Fuel-type NOx is produced by the oxidation of nitrogen atoms present in the fuel in the form of compounds. After the purification process, the content of nitrogen compounds in the gaseous fuel for civil use is very small, and the fuel type NOx has the characteristics of medium temperature generation, and its generation temperature is 600-900 ° C, while the combustion temperature of the existing atmospheric burner is generally higher than this Therefore, atmospheric combustion produces almost no fuel-type NOx.

[0034] 2. About 10% fast NOx, fast NOx is a unique phenomenon when hydrocarbon-rich fuels are burned under the condition of too rich fuel (α<1.0), and it is generated on the inner ...

Embodiment 2

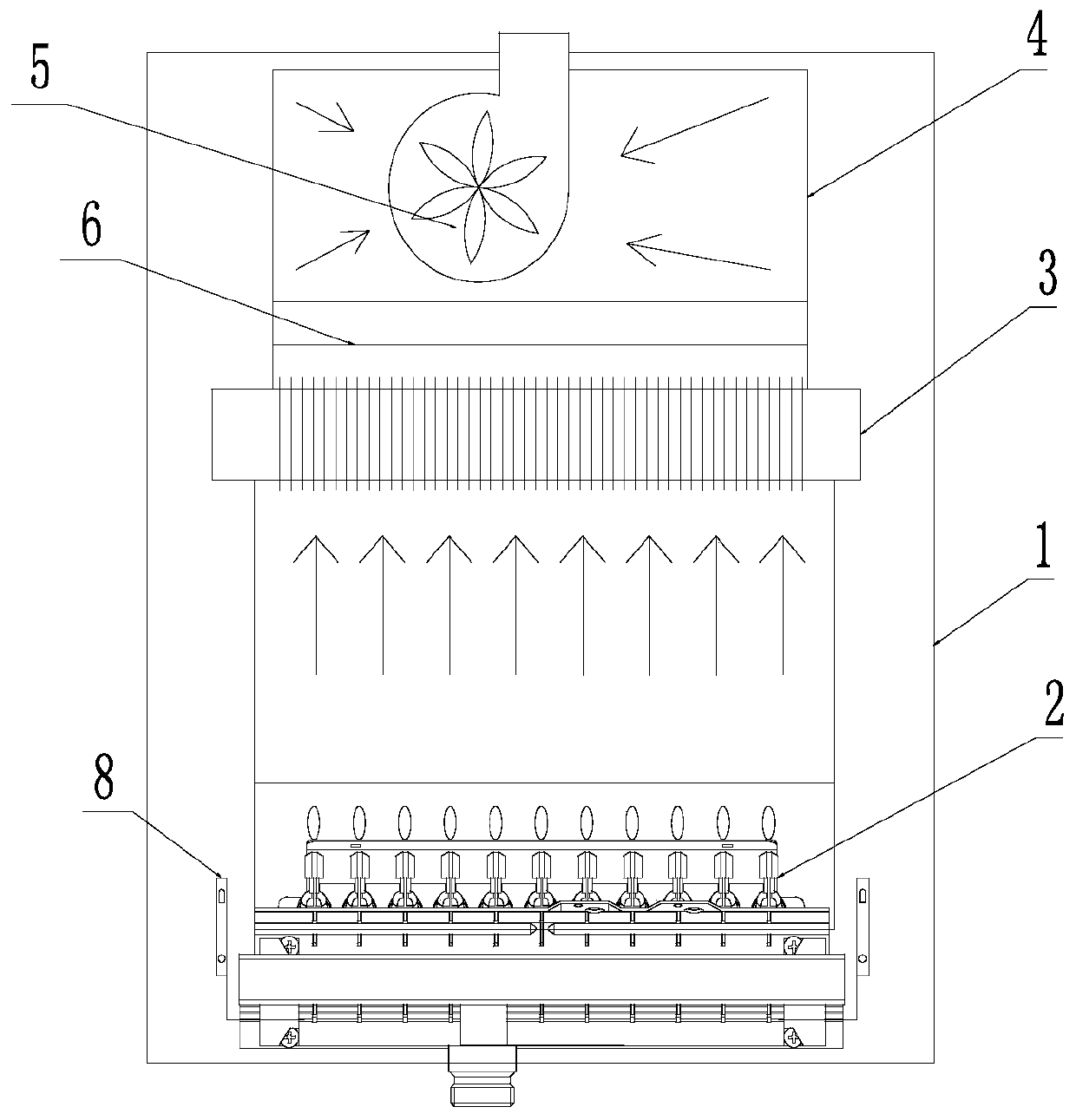

[0042] like figure 1As shown, a gas wall-hung boiler includes a wall-hung furnace body 1, a burner 2, a heat exchanger 3, a smoke collection hood 4 installed in the wall-hung furnace body 1 from bottom to top, and a The blower fan 5 on the smoke hood 4; it is characterized in that a smoke collection hood baffle plate 6 is provided in the smoke collection hood 4, and the surroundings of the smoke collection hood baffle plate 6 are in contact with the inner wall of the smoke collection hood 4, Several air holes 7 are arranged on the baffle plate 6 of the smoke collecting hood.

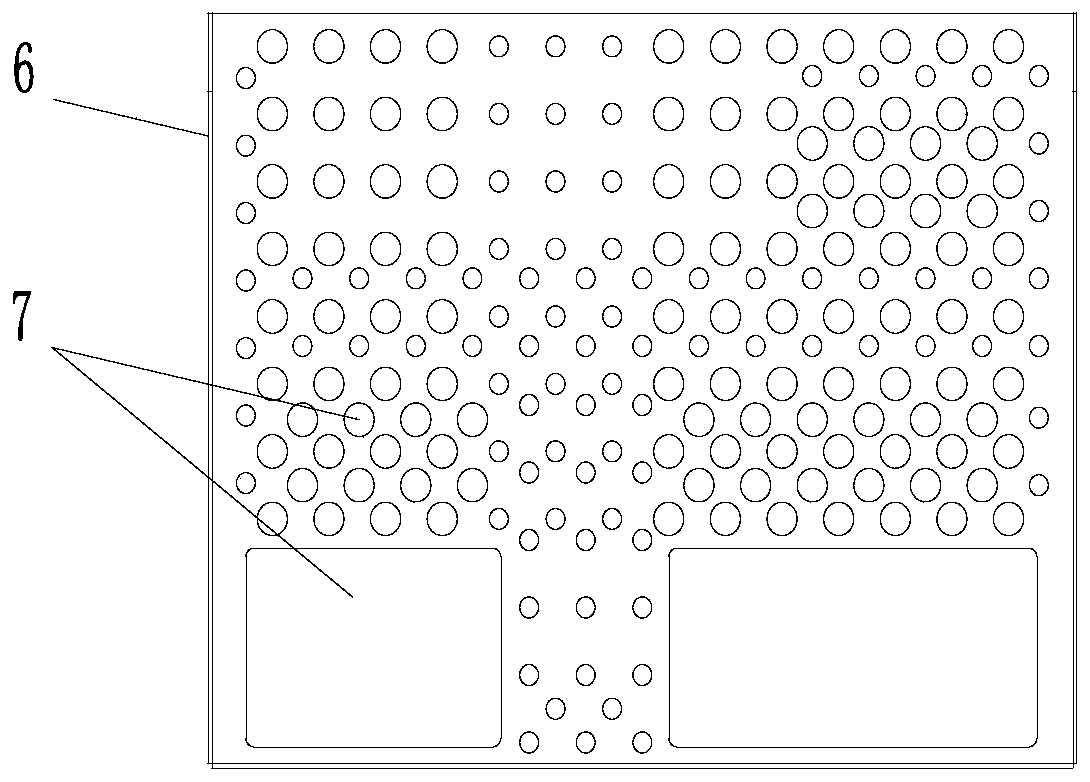

[0043] Among them, such as figure 2 As shown, the ventilation holes 7 include two square holes and several circular holes, the two square holes are located on the front side of the smoke hood baffle plate 6, and have different sizes; the circular holes are randomly distributed in the collection On the fume hood baffle plate 6, there are at least two kinds of holes with different apertures. The openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com