Al-sc-sb-te phase change material, phase change memory unit and preparation method thereof

An al-sc-sb-te, phase-change memory technology, applied in the field of microelectronics, can solve the problems of slow phase change, poor thermal stability and data retention, and achieve strong data retention, convenient material composition, The effect of fast erasing and writing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

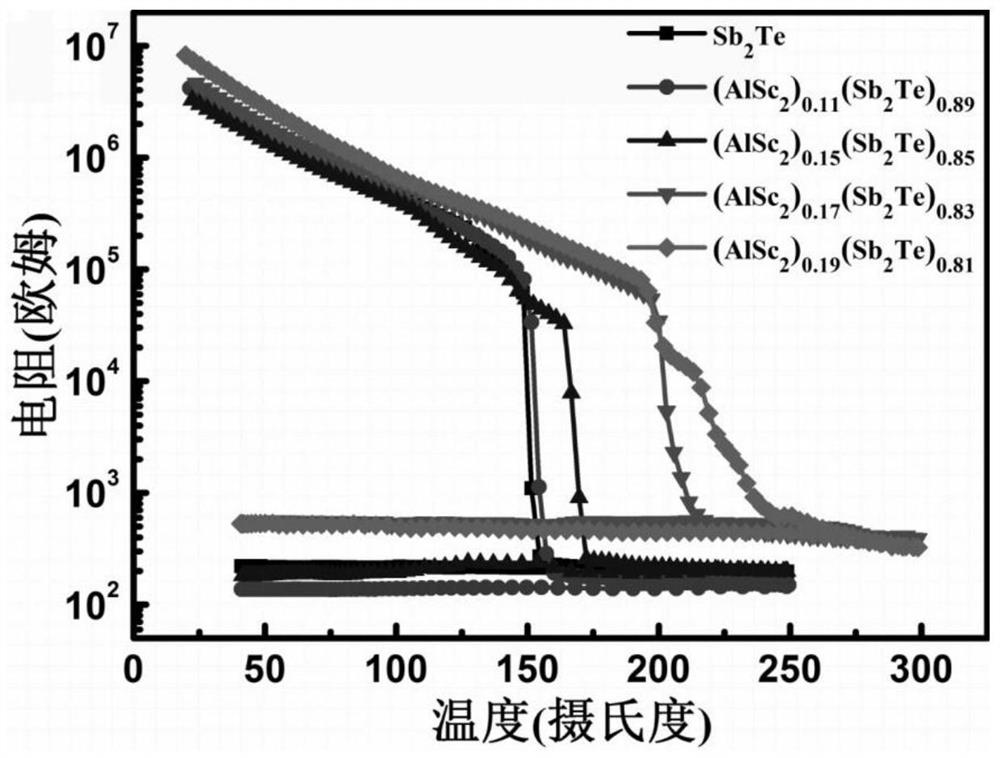

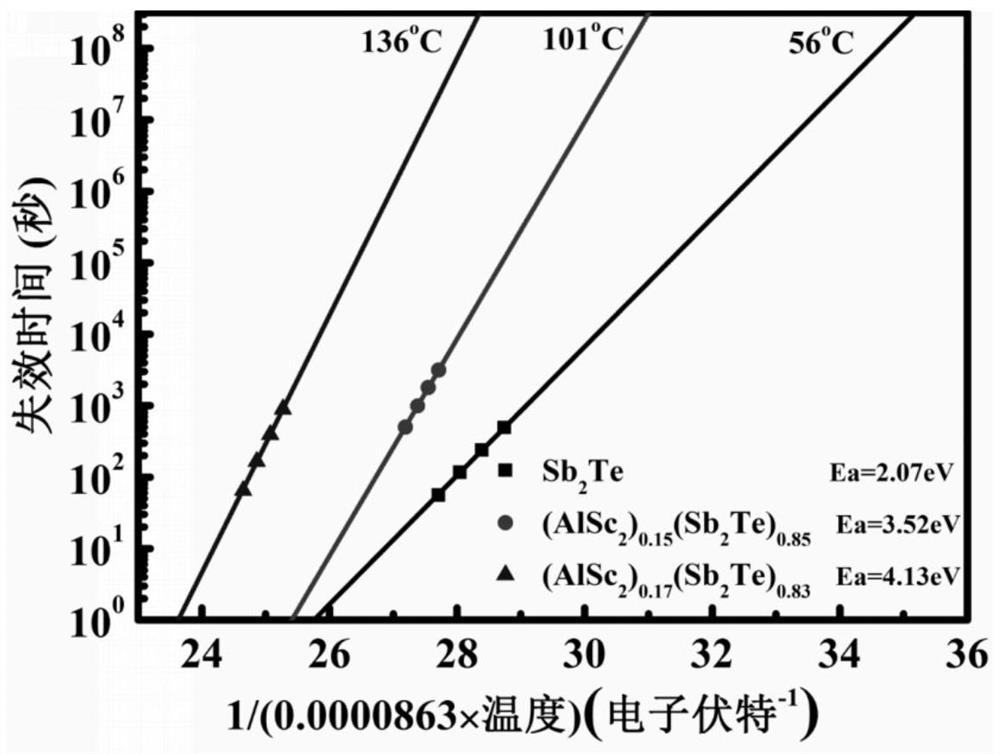

[0039] This embodiment provides an Al-Sc-Sb-Te phase change material, the Al-Sc-Sb-Te phase change material includes aluminum, scandium, antimony, tellurium four elements, the Al-Sc-Sb-Te The general chemical formula of phase change materials is (AlSc 2 ) x (Sb 2 Te) y , where 0<x≤1, 0<y≤1, and x+y=1.

[0040] As an example, the chemical formula of Al-Sc-Sb-Te phase change material (AlSc 2 ) x (Sb 2 Te) yAmong them, 0.11≤x≤0.19, 0.81≤y≤0.89. In more detail, the general formula of the phase change material (AlSc 2 ) x (Sb 2 Te) y The specific components in can be (AlSc 2 ) 0.11 (Sb 2 Te) 0.89 , (AlSc 2 ) 0.15 (Sb 2 Te) 0.85 , (AlSc 2 ) 0.17 (Sb 2 Te) 0.83 and (AlSc 2 ) 0.19 (Sb 2 Te) 0.81 , with an error range of 0.6 mol%. The material system can obtain different crystallization temperature, resistivity and crystallization activation energy by adjusting the ratio between elements.

[0041] As an example, the Al-Sc-Sb-Te phase change material can rea...

Embodiment 2

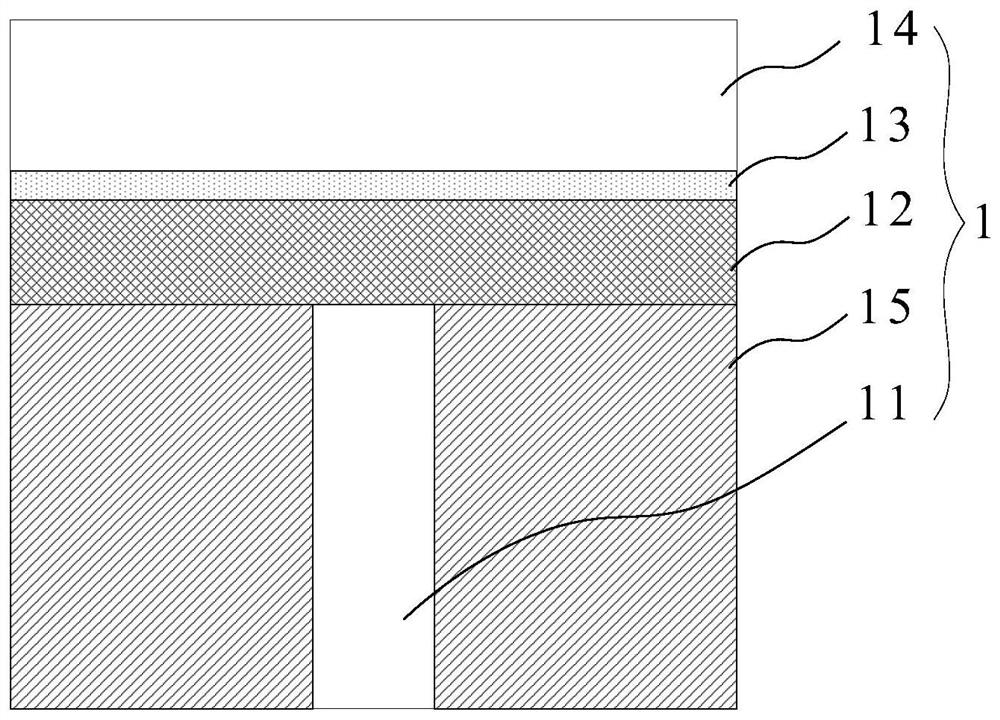

[0048] This embodiment provides a phase change memory cell, the phase change memory cell at least includes a lower electrode layer, an upper electrode layer, and a phase change material layer between the lower electrode layer and the upper electrode layer, the phase change The change material layer includes the Al-Sc-Sb-Te phase change material provided in Embodiment 1, that is, the Al-Sc-Sb-Te phase change material includes four elements of aluminum, scandium, antimony and tellurium, and the Al The general chemical formula of -Sc-Sb-Te phase change material is (AlSc 2 ) x (Sb 2 Te) y , where 0<x≤1, 0<y≤1, and x+y=1.

[0049] It should be noted that the Al-Sc-Sb-Te phase-change thin film material in Example 1 can be used in phase-change memory cells with vertical structures, such as image 3 As shown, the phase-change memory cell 1 includes a lower electrode layer 11 , an Al-Sc-Sb-Te phase-change material layer 12 provided by the present invention, a transition layer 13 , ...

Embodiment 3

[0054] The present invention also provides a method for preparing an Al-Sc-Sb-Te phase-change memory unit, which can prepare the phase-change memory unit in Example 2, and the preparation method at least includes:

[0055] 1) preparing the lower electrode layer;

[0056] 2) preparing a phase-change material layer on the lower electrode layer, the phase-change material layer comprising the Al-Sc-Sb-Te phase-change material described in Example 1;

[0057] 3) Prepare an upper electrode layer on the phase change material.

[0058] As an example, the lower electrode layer may be prepared using a sputtering method, an evaporation method, a chemical vapor deposition method (CVD), a plasma enhanced chemical vapor deposition method (PECVD), or the like. The material of the lower electrode layer includes: one of Al, Ti, W, graphite, TiN, Cu, and TiW. In this embodiment, the material of the lower electrode layer 11 is preferably W.

[0059] As an example, the Al-Sc-Sb-Te phase change...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com