Carbon dioxide capturing system and method based on waste heat recycling of turbine exhaust steam

A waste heat recovery and carbon dioxide technology, applied in chemical instruments and methods, separation methods, indirect heat exchangers, etc., can solve the problems of insufficient recovery and utilization of heat flow energy, waste of heat energy, etc., to improve steam utilization rate and power generation efficiency, The effect of high energy efficiency utilization and reduction of cooling water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

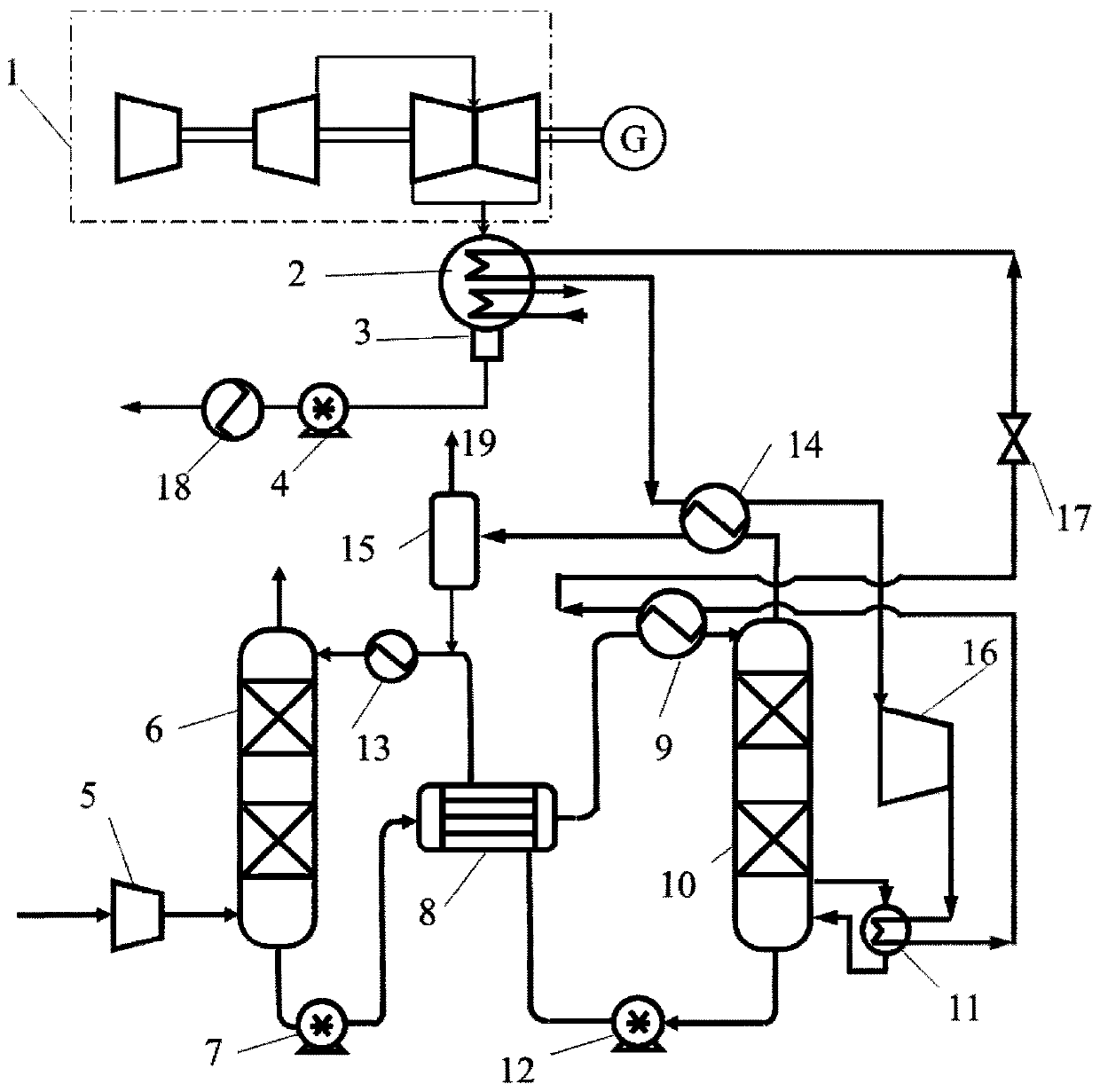

[0018] Example 1, see figure 1 , a carbon dioxide capture system based on steam turbine exhaust heat recovery and utilization, including a carbon dioxide capture subsystem and a heat pump subsystem based on steam turbine exhaust heat recovery;

[0019] The carbon dioxide capture subsystem includes an induced draft fan 5, an absorption tower 6, a rich liquid pump 7, a lean / rich liquid heat exchanger 8, a rich liquid heat exchanger 9, a desorption tower 10, a reboiler 11, and a lean liquid pump 12 , lean liquid cooler 13, tower top gas heat exchanger 14 and gas-liquid separator 15.

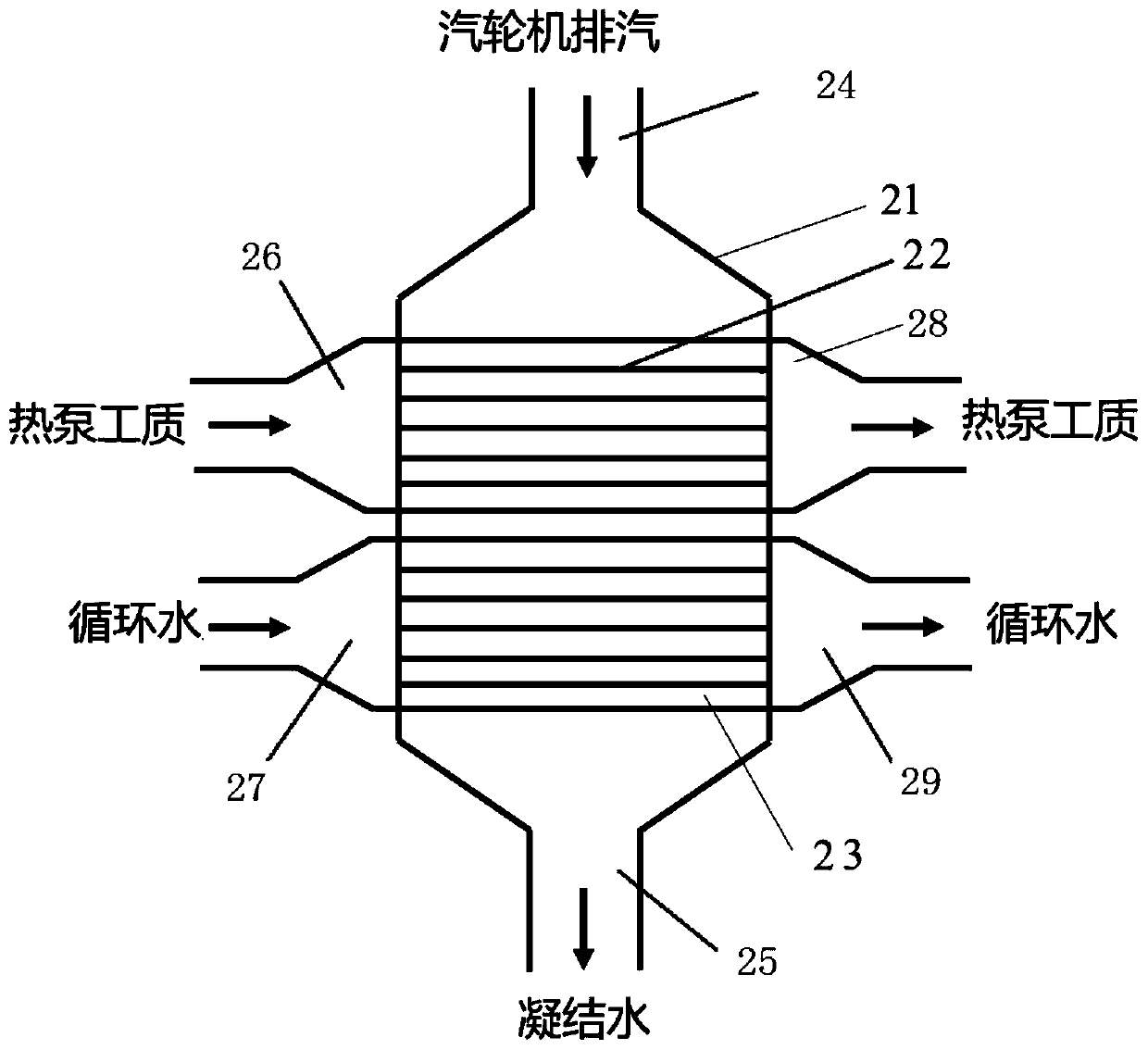

[0020] The heat pump subsystem based on steam turbine exhaust heat recovery includes a condenser 2 , an overhead gas heat exchanger 14 , a compressor 16 , a reboiler 11 , a rich liquid heat exchanger 9 and a throttle valve 17 .

[0021] In the carbon dioxide capture subsystem, the absorption tower 6 has a bottom gas inlet for the CO-containing gas introduced through the induced draft fan 5. 2 The ...

Embodiment 2

[0029] Embodiment 2, a carbon dioxide capture method based on the recovery and utilization of waste heat from steam turbine exhaust, comprising the following steps: externally purified CO-containing 2 After the flue gas is pressurized by the induced draft fan 5, it enters the absorption tower 6 from the gas inlet at the bottom of the absorption tower 6, and contacts with the lean liquid entering from the liquid inlet at the top of the absorption tower in countercurrent, and the lean liquid absorbs the carbon dioxide in the flue gas and becomes a rich liquid, which is processed The final flue gas is sent from the top gas outlet to the subsequent delivery pipeline; the rich liquid flows out from the liquid outlet at the bottom of the absorption tower, and is boosted by the rich liquid pump 7 to enter the lean / rich liquid heat exchanger 8 and the high-temperature CO 2 The absorbent performs heat exchange, recovers the heat of the high-temperature lean liquid from the lean liquid p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com