Microplastic Forming Method of Titanium Alloy Microgear

A titanium alloy and micro-gear technology, applied in metal extrusion control equipment, metal extrusion, metal processing equipment, etc., can solve the problems of cumbersome procedures, time-consuming and labor-consuming, slow pulse current response, complex mold structure, etc., and achieve The effects of good isometricity, improved filling quality and simple mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

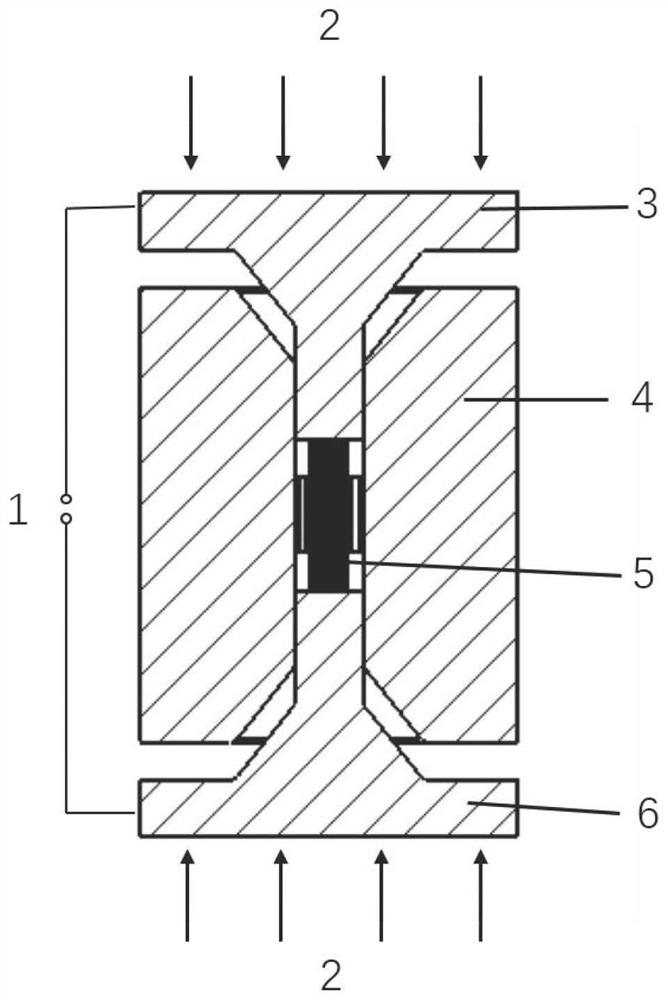

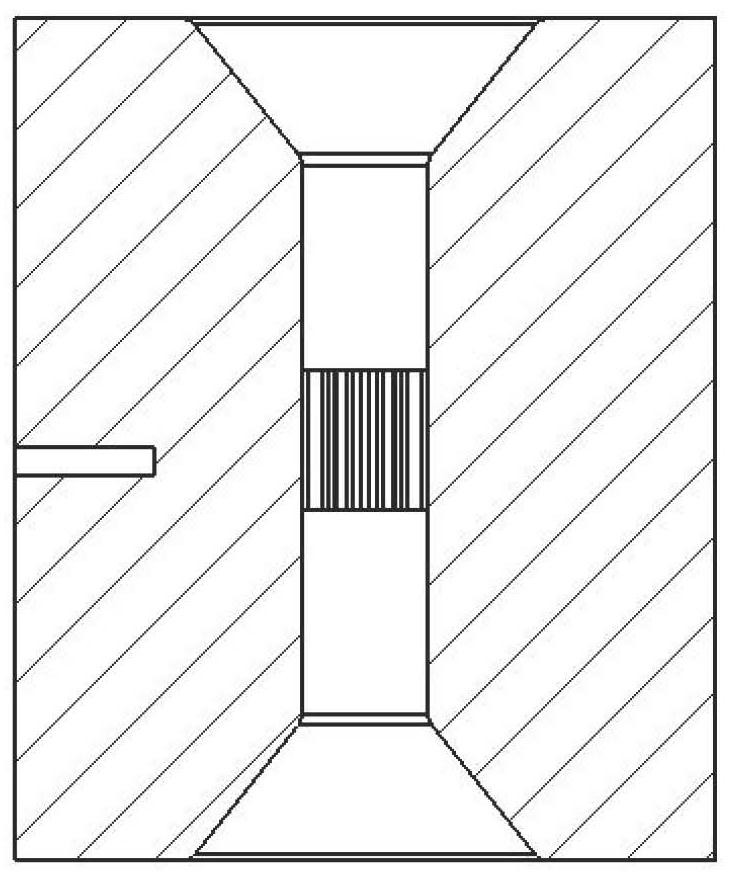

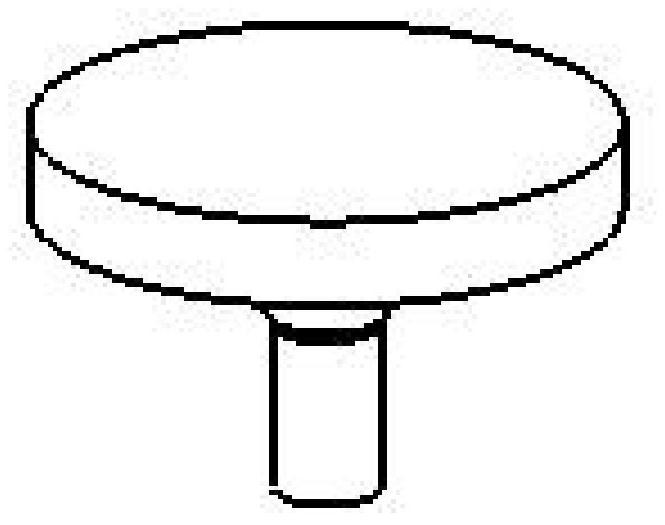

[0042] Fill the TC4 titanium alloy billet into the mold, and then heat the mold with the TC4 titanium alloy billet with alternating current 1 under the condition of vacuum degree ≤ 0.01Pa and heating rate of 30°C / s, and keep it warm when the temperature rises to 1000°C 60s, and then apply an extrusion force 2 at both ends of the mold. Under the continuous coupling of electric field, temperature field and force field, the TC4 titanium alloy billet undergoes microplastic deformation to form a microgear. Finally, the microgear is taken out after power off and air cooling.

[0043] After testing, the Vickers hardness of the obtained microgear part is 374.4HV, and the dimensional accuracy error is ≤100μm.

Embodiment 2

[0045] Fill the TC4 titanium alloy billet into the mold, and then heat the mold with the TC4 titanium alloy billet with alternating current 1 under the condition of vacuum degree ≤0.01Pa and heating rate of 30°C / s, and keep it warm when the temperature rises to 1200°C 60s, and then apply an extrusion force 2 at both ends of the mold. Under the continuous coupling of electric field, temperature field and force field, the TC4 titanium alloy billet undergoes microplastic deformation to form a microgear. Finally, the microgear is taken out after power off and air cooling.

[0046] After testing, the Vickers hardness of the obtained micro-gear part is 365.6HV, and the dimensional accuracy error is ≤50 μm.

Embodiment 3

[0048] Fill the TC4 titanium alloy billet into the mold, and then heat the mold with the TC4 titanium alloy billet with alternating current 1 under the condition of vacuum degree ≤ 0.01Pa and heating rate of 50°C / s, and keep it warm when the temperature rises to 1200°C 120s, and then apply extrusion force 2 at both ends of the mold. Under the continuous coupling of electric field, temperature field and force field, the TC4 titanium alloy billet undergoes microplastic deformation to form a microgear. Finally, the microgear is taken out after power off and air cooling.

[0049] After testing, the Vickers hardness of the obtained micro-gear part is 360.6HV, and the dimensional accuracy error is ≤30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com