Electric locomotive pantograph type current collector head of multi-ring structure

An electric locomotive, multi-ring structure technology, applied in the field of rail transit, can solve the problems of airway damage, increase the flow of the sliding plate and the contact line, instability, etc., so as to reduce the probability of arcing and efficiently fit the contact line. , The effect of stable flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

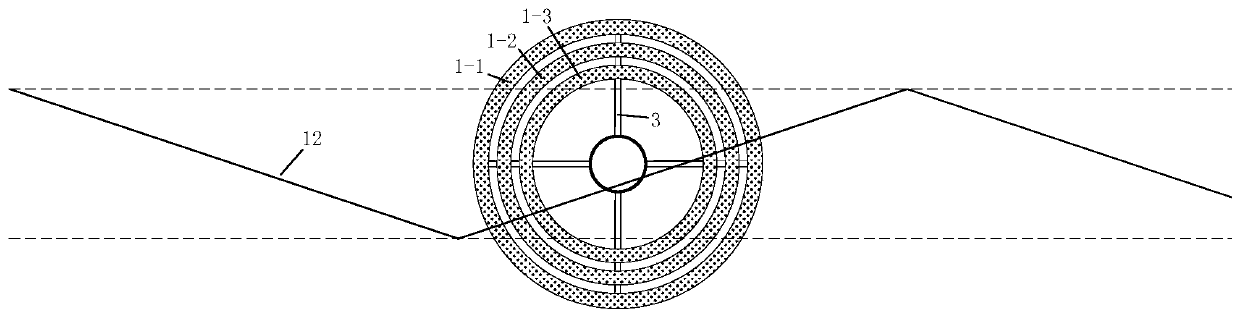

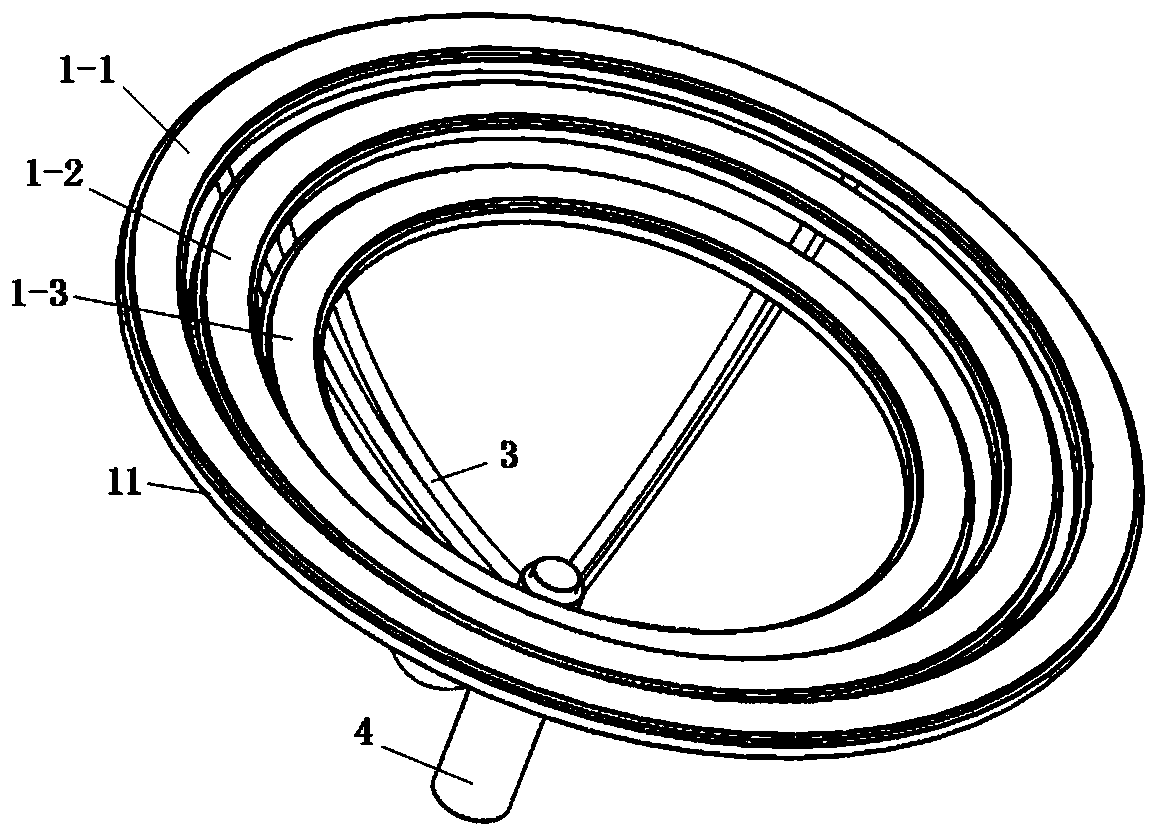

[0030] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It shows a pantograph head of an electric locomotive with multi-ring structure, and the circular rotating disk 8-1 and the disk-shaped insulating base 8-2 in it form a rotational fit relationship through balls 8-3 The structure of the support arm base 4 is: the lower part of the inner cylinder 4-1 is movable in the middle cylinder 4-2, the lower part of the middle cylinder 4-2 is movable in the outer cylinder 4-1, and the inner cylinder and the middle There is an inner cylinder lifting structure 9 between the cylinders: two gears 13 driven by motors are rotatably installed in the middle cylinder, one on the left and one on the right. Two rows of ring-shaped tooth protrusions 14 are meshed, the above-mentioned motor is installed in the middle barrel through the motor seat, the motor seat is fixed on the inner wall of the middle barrel, the motor shaft is connected with one end of the gear 13 shaft through a coup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com