A kind of styrene-acrylic emulsion toughened geopolymer and preparation method thereof

A technology of styrene-acrylic emulsion and geopolymer, which is applied in the field of styrene-acrylic emulsion toughened geopolymer and its preparation, can solve the problems of general improvement of folding ratio, etc., and achieve improved mechanical properties and excellent flexural and compressive strength And the folding ratio, the effect of improving the brittleness problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

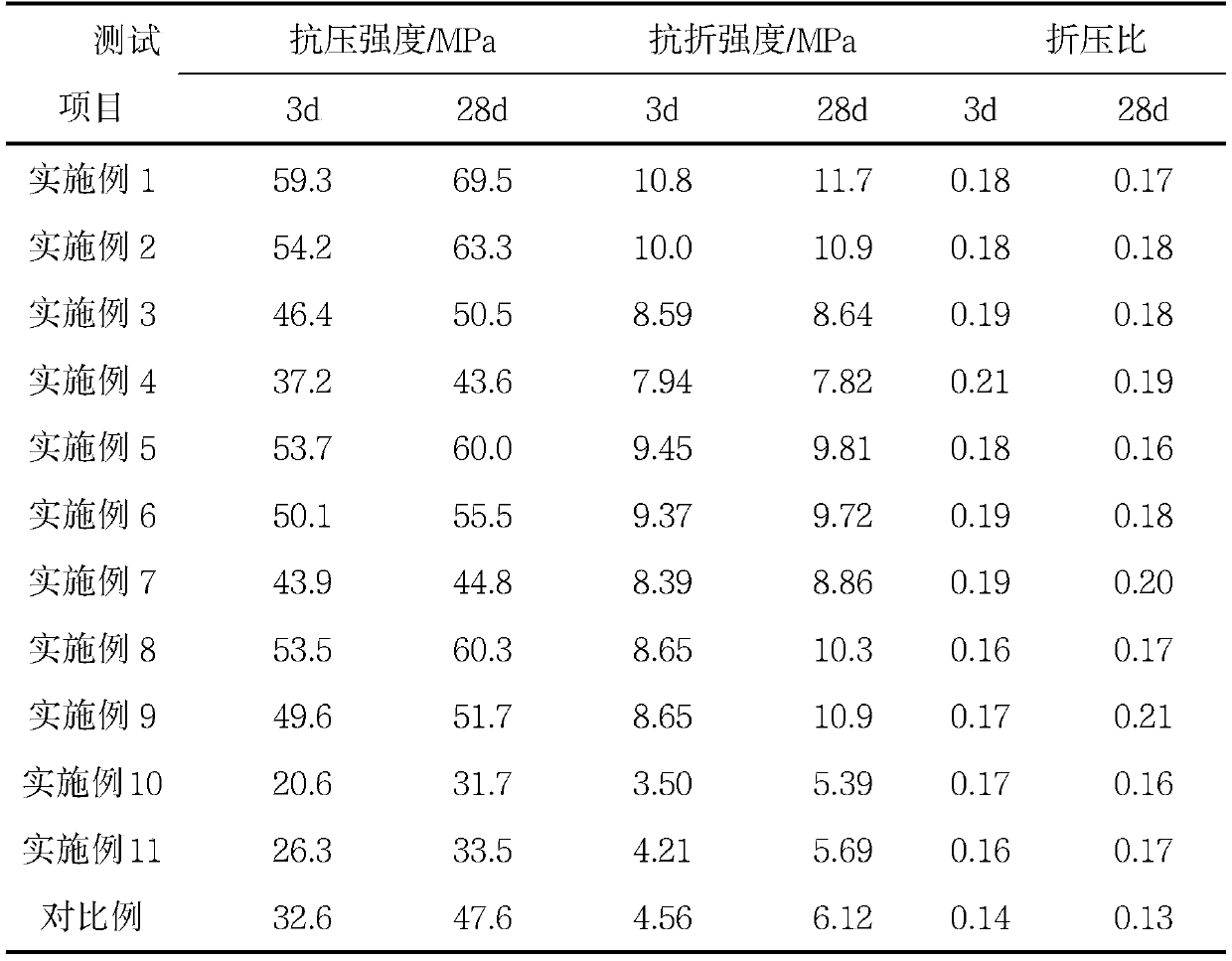

Examples

Embodiment 1

[0021] A styrene-acrylic emulsion toughened polymer, comprising the following raw materials in parts by weight:

[0022] 100 parts of silicon-aluminum raw material (metakaolin), 70 parts of alkali activator, 0.5 part of toughening agent;

[0023] The preparation method of the alkali activator: 20 parts of sodium hydroxide and 80 parts of water glass solution with a modulus of 3.4 were mixed and stirred until all the sodium hydroxide solids were dissolved, and then left to stand for 24 hours to obtain the alkali activator.

[0024] The preparation method of the toughening agent: add 6 parts of silane coupling agent A-151 to 50 parts of styrene-acrylic emulsion, mix and react at 60°C to obtain the product.

[0025] The preparation method of the above-mentioned styrene-acrylic emulsion toughened polymer: mix and stir the silicon-aluminum raw material and the alkali activator at a speed of 10-50r / min for 2min in parts by weight, then add the toughening agent, Mix and stir for 2 m...

Embodiment 2

[0027] A styrene-acrylic emulsion toughened polymer, comprising the following raw materials in parts by weight:

[0028] 100 parts of silicon-aluminum raw material (metakaolin), 70 parts of alkali activator, 1 part of toughening agent;

[0029] The preparation method of the alkali activator: 20 parts of sodium hydroxide and 80 parts of water glass solution with a modulus of 3.4 were mixed and stirred until all the sodium hydroxide solids were dissolved, and then left to stand for 24 hours to obtain the alkali activator.

[0030] The preparation method of the toughening agent: add 6 parts of silane coupling agent A-151 to 50 parts of styrene-acrylic emulsion, mix and react at 60°C to obtain the product.

[0031] The preparation method of the above-mentioned styrene-acrylic emulsion toughened polymer: mix and stir the silicon-aluminum raw material and the alkali activator at a speed of 10-50r / min for 2min in parts by weight, then add the toughening agent, Mix and stir for 2 min...

Embodiment 3

[0033] A styrene-acrylic emulsion toughened polymer, comprising the following raw materials in parts by weight:

[0034] 100 parts of silicon-aluminum raw material (metakaolin), 70 parts of alkali activator, 2 parts of toughening agent;

[0035] The preparation method of the alkali activator: 20 parts of sodium hydroxide and 80 parts of water glass solution with a modulus of 3.4 were mixed and stirred until all the sodium hydroxide solids were dissolved, and then left to stand for 24 hours to obtain the alkali activator.

[0036] The preparation method of the toughening agent: add 6 parts of silane coupling agent A-151 to 50 parts of styrene-acrylic emulsion, mix and react at 60°C to obtain the product.

[0037] The preparation method of the above-mentioned styrene-acrylic emulsion toughened polymer: mix and stir the silicon-aluminum raw material and the alkali activator at a speed of 10-50r / min for 2min in parts by weight, then add the toughening agent, Mix and stir for 2 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com