A kind of preparation method of amidated carbon quantum dot

A technology of amidated carbon and quantum dots, which is applied in the field of preparation of amidated carbon quantum dots, can solve problems such as low quantum yield, and achieve the effect of single raw material, simple hydrothermal synthesis method, and high quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

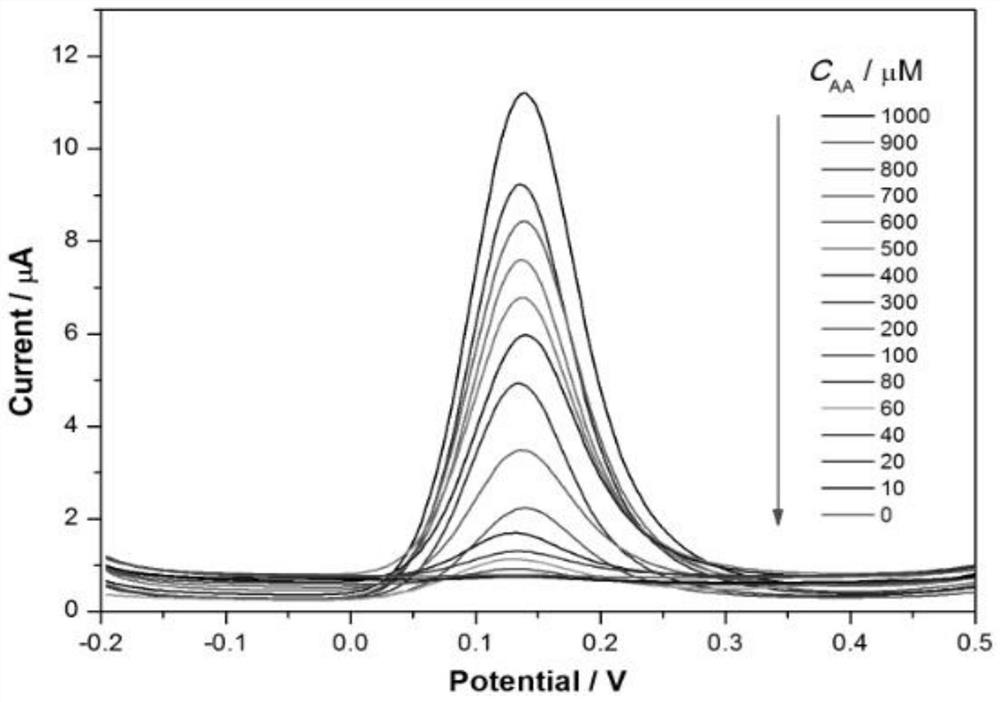

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of amidated carbon quantum dots, the specific steps are as follows:

[0029] (1) Dissolving histidine in sodium hydroxide solution and ultrasonically treating it for 10 min at an ultrasonic power of 20 kHz to obtain mixed solution A; wherein the concentration of sodium hydroxide solution is 10 mg / mL, and the concentration of histidine and sodium hydroxide solution The solid-to-liquid ratio g:mL is 1:10;

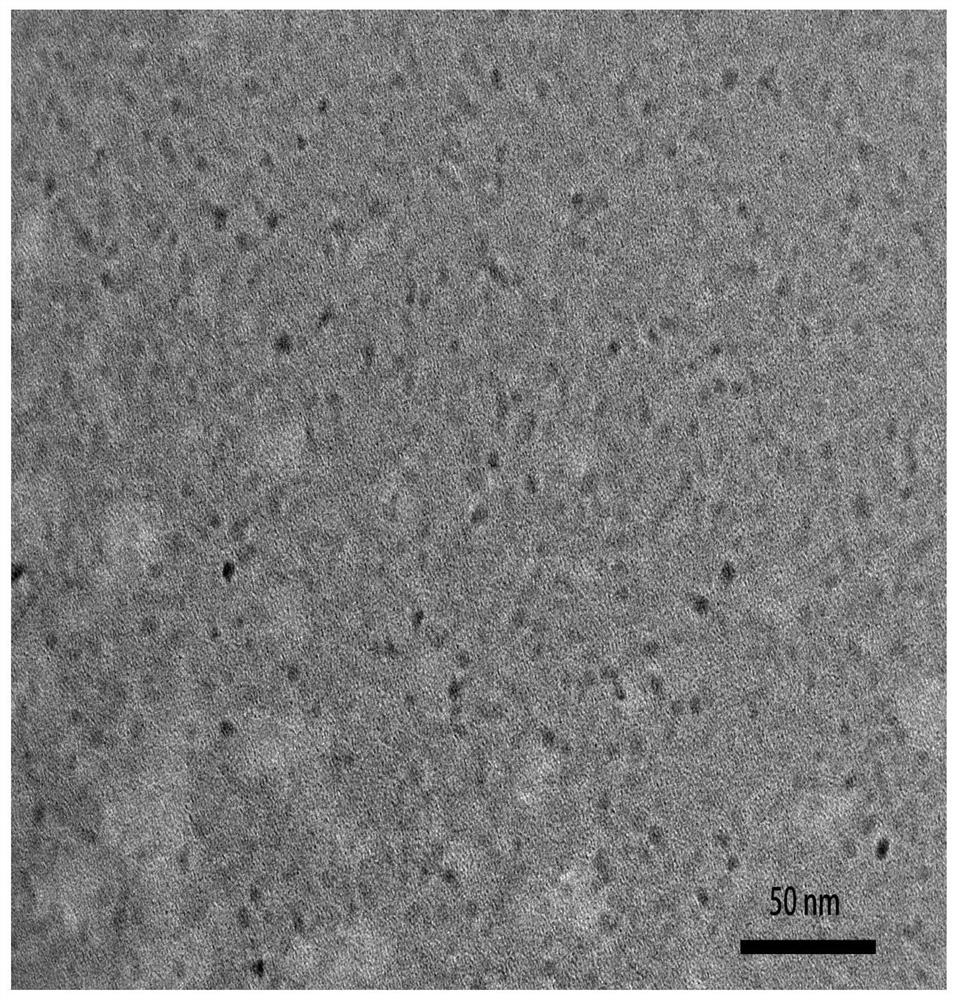

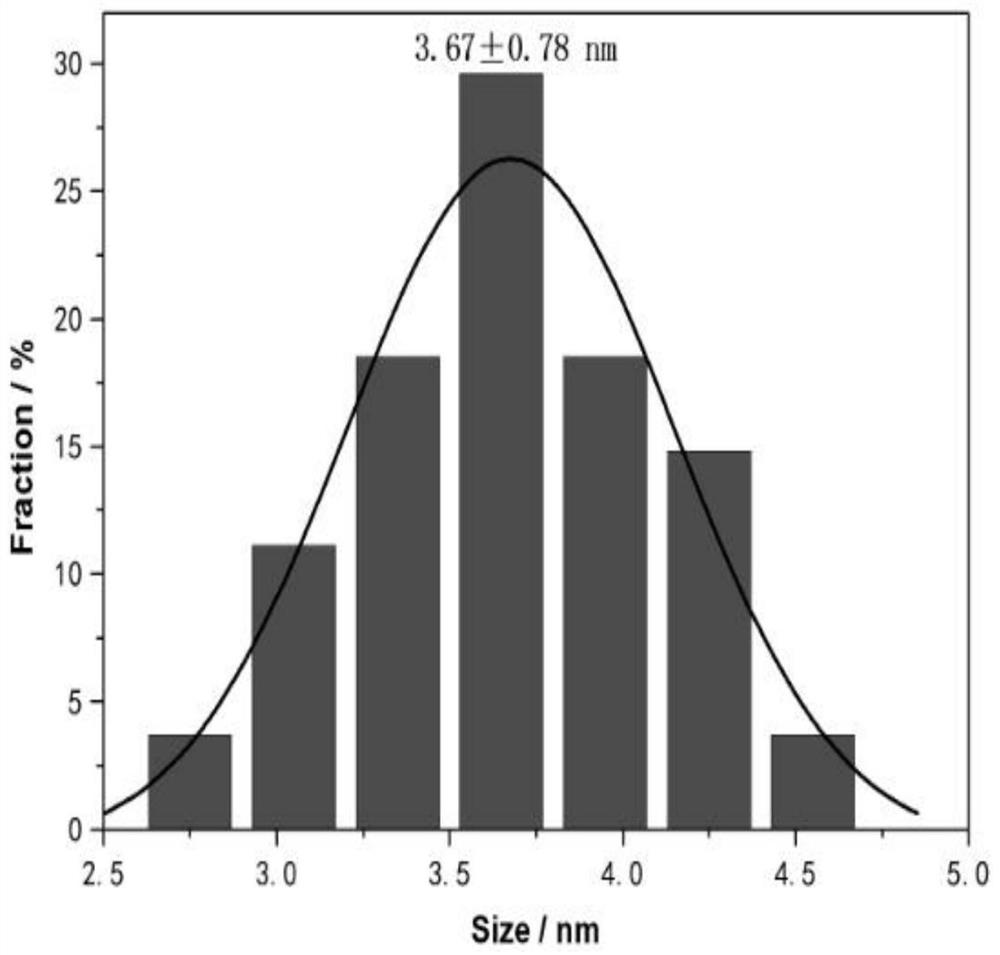

[0030] (2) Put the mixed solution A in step (1) under the condition of 200° C. for hydrothermal reaction for 12 hours, cool it down to room temperature naturally, and filter out large particles to obtain filtrate B; wherein the pore size of the filtered filter membrane is 0.22 μm;

[0031] (3) The filtrate B of step (2) is centrifuged, and the supernatant is taken; wherein the rotating speed of the centrifugation is 10000r / min, and the time of the centrifugation is 20min;

[0032] (4) The supernatant of step (3) is dialyzed through the dialysis me...

Embodiment 2

[0048] A preparation method of amidated carbon quantum dots, the specific steps are as follows:

[0049] (1) dissolving histidine in sodium hydroxide solution and ultrasonically treating 15 min at an ultrasonic power of 15 kHz to obtain mixed solution A; wherein the concentration of sodium hydroxide solution is 10 mg / mL, the concentration of histidine and sodium hydroxide solution The solid-to-liquid ratio g:mL is 1:5;

[0050] (2) Put the mixed solution A in step (1) under the condition of 180°C for hydrothermal reaction for 15 hours, naturally cool to room temperature, and filter to obtain filtrate B; wherein the filtered filter membrane has a pore size of 0.35 μm;

[0051] (3) The filtrate B of step (2) is centrifuged, and the supernatant is taken; wherein the rotating speed of the centrifugation is 8000r / min, and the time of the centrifugation is 30min;

[0052] (4) The supernatant of step (3) is dialyzed through a dialysis membrane to obtain an amidated carbon quantum do...

Embodiment 3

[0067] A preparation method of amidated carbon quantum dots, the specific steps are as follows:

[0068] (1) Dissolving histidine in sodium hydroxide solution and ultrasonically treating 5 min at an ultrasonic power of 30 kHz to obtain mixed solution A; wherein the concentration of sodium hydroxide solution is 8 mg / mL, the concentration of histidine and sodium hydroxide solution The solid-to-liquid ratio g:mL is 1:15;

[0069] (2) Put the mixed solution A in step (1) at a temperature of 220° C. for a hydrothermal reaction for 10 h, cool it down to room temperature naturally, and filter to obtain a filtrate B; wherein the filtered filter membrane has a pore size of 0.25 μm;

[0070] (3) The filtrate B of step (2) is centrifuged, and the supernatant is taken; wherein the rotating speed of the centrifugation is 12000r / min, and the time of the centrifugation is 10min;

[0071] (4) The supernatant of step (3) is dialyzed through the dialysis membrane to obtain the amidated carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com