Polyimide fiber with multi-block structure and preparation method and application thereof

A polyimide fiber, multi-block technology, applied in the field of polyimide fiber with multi-block structure and its preparation, to achieve excellent mechanical properties, environmentally friendly process, and the effect of being conducive to mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

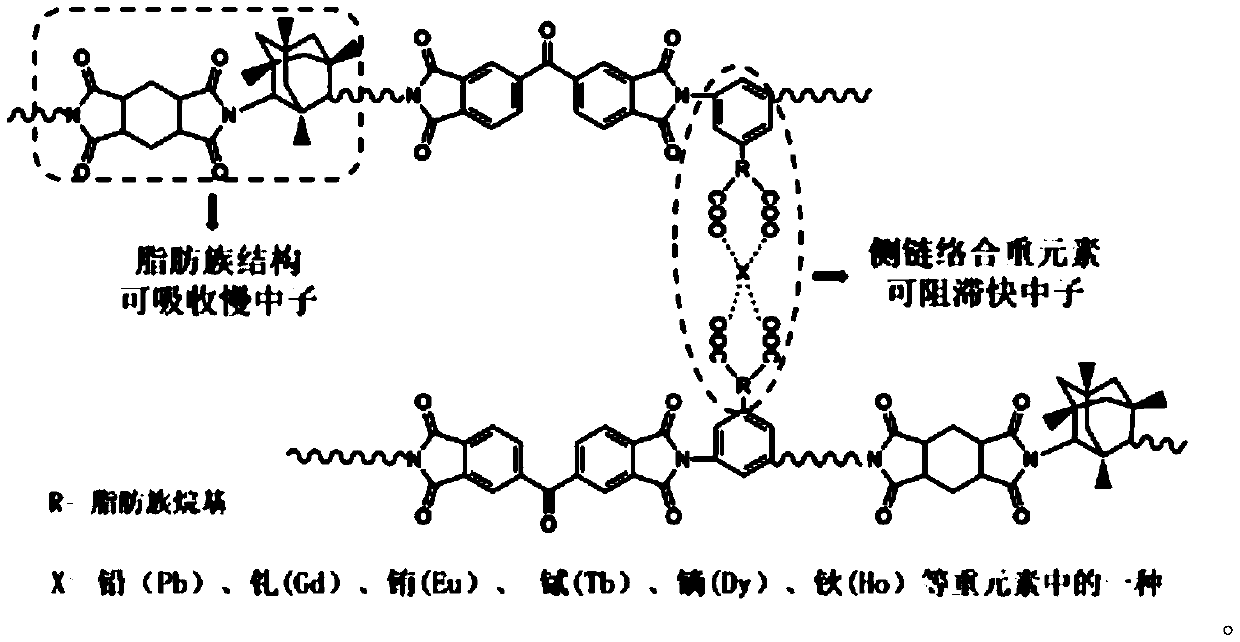

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Under nitrogen protection, in a 250mL three-necked flask, add 120mL of NMP, 7.8g (0.04mol) of 6,8-adamantanediamine (Sinopharm Reagent, analytically pure), 10g (0.045mol)1, 2,4,5-Cyclohexanetetracarboxylic dianhydride (hydrogenated PMDA, Changzhou Sunshine Pharmaceutical Co., Ltd., analytically pure) was stirred and reacted at 5°C for 10 h to obtain solution A.

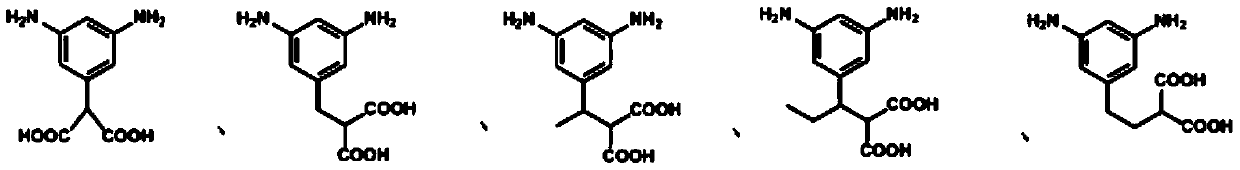

[0039] (2) Under nitrogen protection, in a 500mL three-necked flask, add 120mL of NMP, 9.4g (0.045mol) of 2-(3,5-diaminophenyl)malonic acid (Sinopharm Reagent, analytically pure), 12.9 g (0.04 mol) of 3,3',4,4'-benzophenonetetra-acid dianhydride (BTDA, Changzhou Sunshine Pharmaceutical Co., Ltd., analytical grade) was stirred and reacted at 5° C. for 10 h to obtain solution B.

[0040] (3) Under the protection of nitrogen, pour solution A in step (1) into solution B in step (2), continue to stir at 5°C for 6h, then react at 125°C, 145°C, and 165°C for 1h at each constant temperature, and finally Raise the ...

Embodiment 2

[0045](1) Under nitrogen protection, in a 250mL three-necked flask, add 130mL of DMAc, 8.32g (0.043mol) of 3,7-adamantanediamine (Sinopharm Reagent, analytically pure), 12g (0.054mol) of hydrogenated PMDA (Changzhou Sunshine Pharmaceutical Co., Ltd., analytically pure), stirred and reacted at 5°C for 8 hours to obtain solution A.

[0046] (2) Under nitrogen protection, in a 500mL three-necked flask, add 140mL of DMAc, 11.5g (0.054mol) of 2-(3,5-diaminophenyl)malonic acid (Sinopharm Reagent, analytically pure), 13.8 g (0.043 mol) of 3,3',4,4'-benzophenonetetraacid dianhydride (BTDA, Changzhou Sunshine Pharmaceutical Co., Ltd., analytically pure) was stirred and reacted at 5°C for 8 hours to obtain solution B.

[0047] (3) Under the protection of nitrogen, pour solution A in step (1) into solution B in step (2), continue to stir at 5°C for 6h, then react at 125°C, 145°C, and 165°C for 1h at each constant temperature, and finally Raise the temperature to 185° C. and react for 18...

Embodiment 3

[0052] (1) Under the protection of nitrogen, in a 250mL three-necked flask, add 125mL of NMP, 7.43g (0.038mol) of 4,6-adamantanediamine (Sinopharm Reagent, analytically pure), 15g (0.077mol) of cyclobutane Alkanedianhydride (Changzhou Sunshine Pharmaceutical Co., Ltd., analytically pure) was stirred and reacted at 5°C for 9 hours to obtain solution A.

[0053] (2) Under the protection of nitrogen, in a 500mL three-necked flask, add 160mL of NMP, 16.0g (0.077mol) of 2-(3,5-diaminophenyl)malonic acid (Sinopharm Reagent, analytically pure), 12.3 g (0.038 mol) of 2,3',3,4'-benzophenone tetraacid dianhydride (Changzhou Sunshine Pharmaceutical Co., Ltd., analytically pure) was stirred and reacted at 5° C. for 9 h to obtain solution B.

[0054] (3) Under the protection of nitrogen, pour solution A in step (1) into solution B in step (2), continue to stir at 5°C for 6h, then react at 125°C, 145°C, and 165°C for 1h at each constant temperature, and finally Raise the temperature to 185...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com