Preparation method and application of sulfur positive electrode of full-wood structure

A technology of sulfur positive electrode and wood structure, applied in the direction of positive electrode, structural parts, battery electrodes, etc., can solve the problems of large volume strain, achieve the effects of alleviating volume effect, improving utilization rate, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

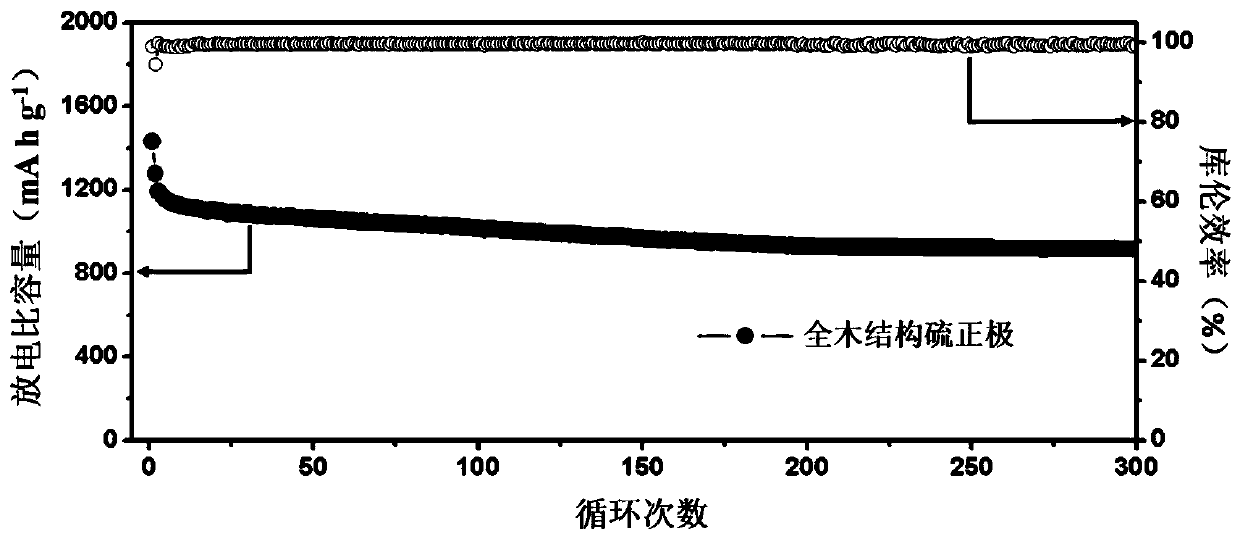

Examples

Embodiment 1

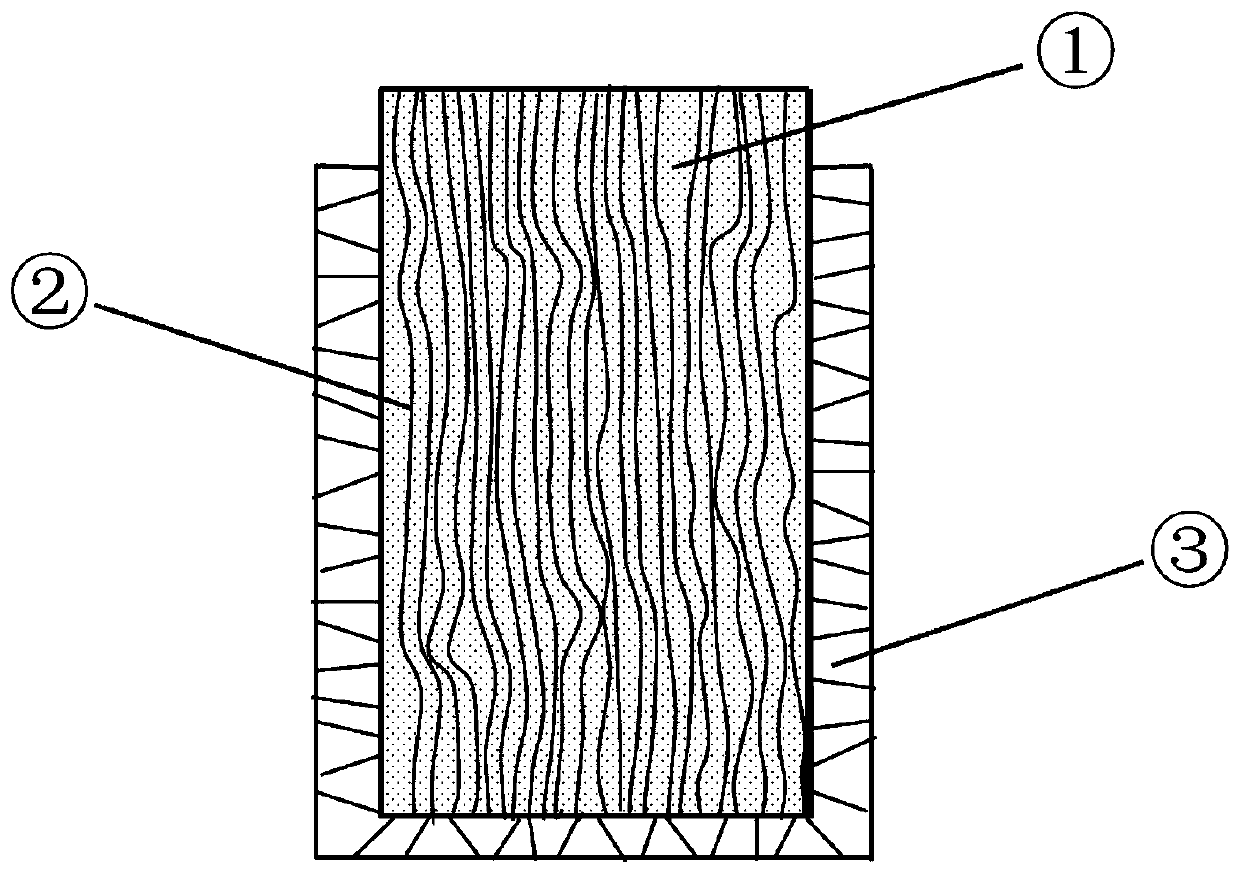

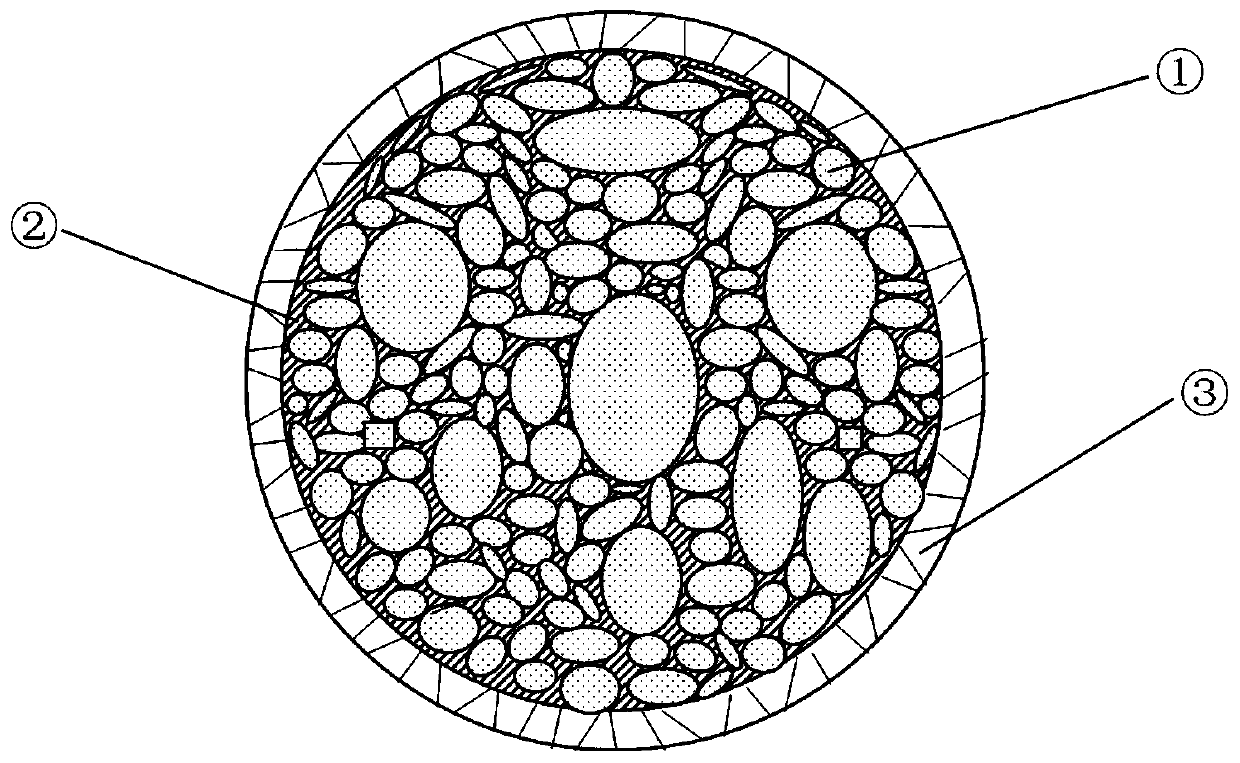

[0037] Step 1: Preparation of the all-wood structure sulfur cathode

[0038] S1. Pretreatment of the carrier

[0039] Get a section of pine as a carrier, process it into a cylindrical shape with a suitable diameter (the suitable diameter means that the outer diameter of the cylindrical carrier matches the inner diameter of the protective sleeve made in step S4), then immerse it in a 2.5mol / L In the sodium hydroxide solution, keep boiling state 12h, wash with distilled water 3 times subsequently, obtain the columnar wooden block carrier that removes organic matter;

[0040] S2, carbonization of the carrier

[0041] The wood block carrier was placed in a tube furnace, and when the tube furnace was filled with an air atmosphere, it was heated to 250 °C at a heating rate of 5 °C / min. After the temperature reached, the carrier was pre-carbonized for 6 h; When the type furnace is filled with argon atmosphere, it is heated up to 1000 °C at a heating rate of 5 °C / min. After the temp...

Embodiment 2

[0053] Step 1: Preparation of the all-wood structure sulfur cathode

[0054] S1. Pretreatment of the carrier

[0055] Get a section of teak as a carrier, process it into a cylindrical shape with a suitable diameter (the suitable diameter means that the outer diameter of the cylindrical carrier matches the inner diameter of the protective sleeve made in step S4), and then immerse it in a 1.5mol / L In the sodium hydroxide solution, keep boiling state 10h, rinse with distilled water 2 times subsequently, obtain the columnar wooden block carrier that removes organic matter;

[0056] S2, carbonization of the carrier

[0057] The wood block carrier was placed in a tube furnace, and when the tube furnace was filled with an air atmosphere, it was heated to 300 °C at a heating rate of 5 °C / min. After the temperature reached, the carrier was pre-carbonized for 7 h; When the furnace is filled with nitrogen atmosphere, it is heated to 1200°C at a heating rate of 5°C / min. After the temper...

Embodiment 3

[0069] Step 1: Preparation of the all-wood structure sulfur cathode

[0070] S1. Pretreatment of the carrier

[0071] Get a section of maple as a carrier, process it into a cylindrical shape with a suitable diameter (the suitable diameter means that the outer diameter of the cylindrical carrier matches the inner diameter of the protective sleeve made in step S4), then immerse it in 4.5mol / In the potassium hydroxide solution of 1, keep boiling state 10h, rinse with distilled water 3 times subsequently, obtain the columnar wooden block carrier that removes organic matter;

[0072] S2, carbonization of the carrier

[0073] The wood block carrier was placed in a tube furnace, and when the tube furnace was filled with an air atmosphere, it was heated to 200 °C at a heating rate of 5 °C / min. After the temperature reached, the carrier was pre-carbonized for 5 h; When the furnace is filled with argon atmosphere, it is heated to 900°C at a heating rate of 5°C / min. After the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com