A welding method for synchronous wire feeding and powder feeding with dual heat sources

A welding method and dual heat source technology, applied in welding equipment, electrode characteristics, arc welding equipment, etc., can solve the problems of small welding pool, fast solidification, difficult to use, etc., to improve the stress state and control the amount of metal filling. Improves and suppresses thermal cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

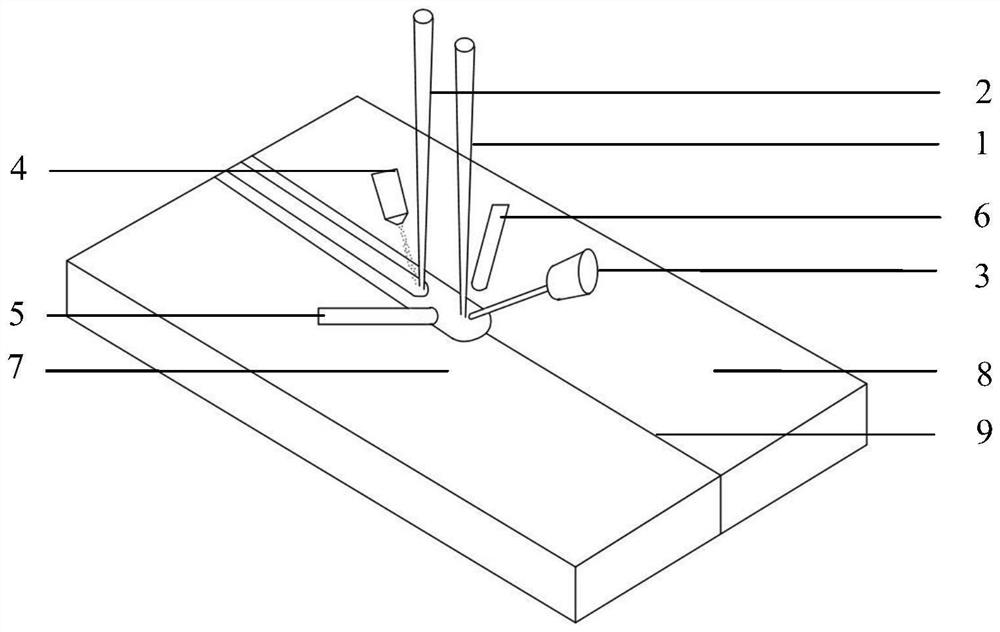

[0042] In this embodiment, a thin metal plate with a thickness of 2mm is selected as the first workpiece to be welded and the second workpiece to be welded, and the plate surfacing welding is carried out under the protection of argon gas. The specific welding steps are as follows:

[0043] (1) Grinding the welding surfaces of the first workpiece 7 to be welded and the second workpiece 8 to be welded to be smooth, cleaning to remove impurities such as oxides and oil stains, and installing the first workpiece 7 to be welded and the second workpiece 8 to be welded On the welding tool, metal plates are placed at both ends of the welding tool as the arc strike plate;

[0044] (2) Arrange the wire feed gun head, front heat source 1, rear heat source 2 and powder feeding nozzle in series along an axis along the forward direction of the welding heat source, and place the side blowing protective gas pipes respectively on the front heat source On both sides of 2, the axis of the trachea...

Embodiment 2

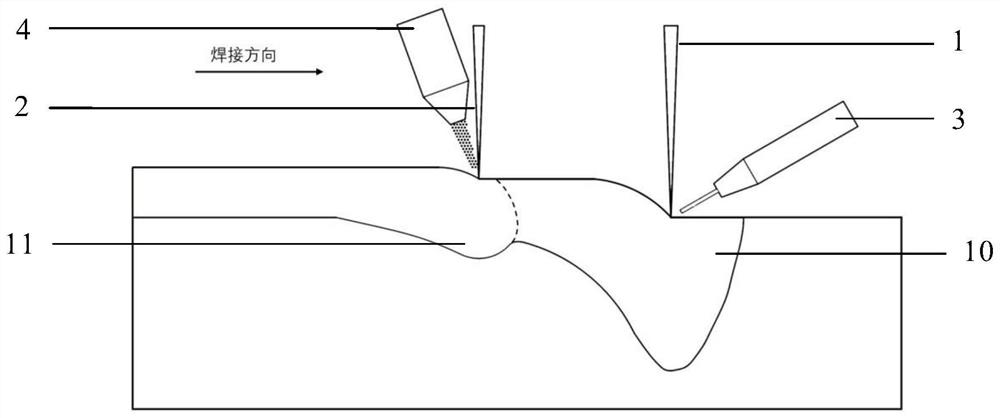

[0051] In this embodiment, a thick metal plate with a thickness of 10mm is selected as the first workpiece to be welded and the second workpiece to be welded, and the thick plate is butt welded under the protection of argon gas. The specific welding steps are as follows:

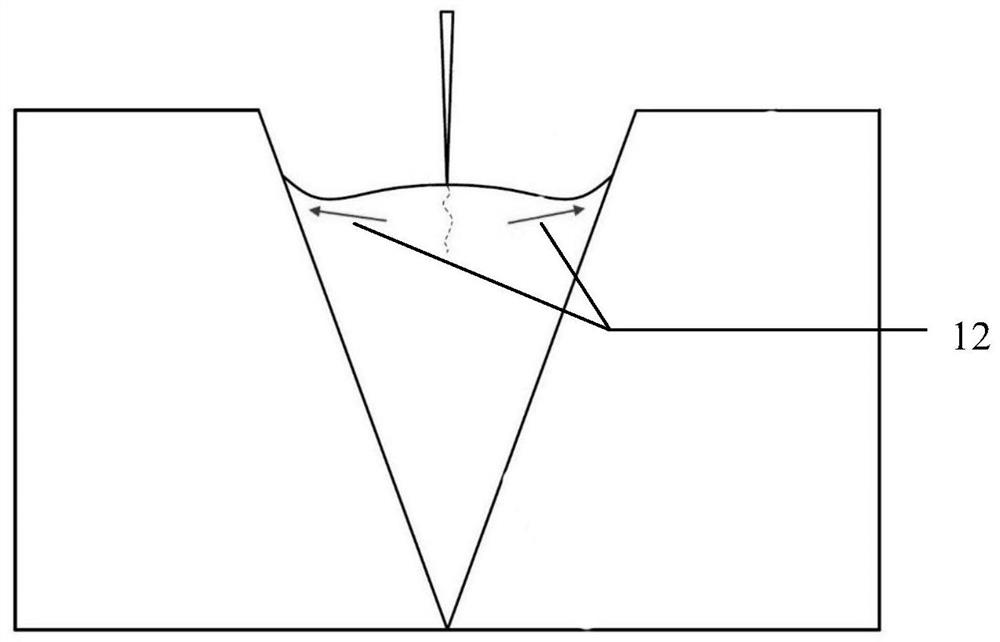

[0052] (1) Open a V-shaped groove on the side of the first workpiece 7 to be welded and the second workpiece 8 to be welded as the welding surface, the groove angle is 20°, the groove depth is 5mm, and the groove is ground to smooth with a grinder Smooth, carry out chemical cleaning to remove impurities such as oxides and oil stains, install the first workpiece to be welded and the second workpiece to be welded on the welding tool, and place metal plates at both ends of the welding tool as arc strike plates;

[0053] (2) Arrange the wire feed gun head, front heat source 1, rear heat source 2 and powder feeding nozzle in series along an axis along the forward direction of the welding heat source, and place the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com