Amino-modified silicone oil containing long-chain alkyl and preparation method of amino-modified silicone oil

A technology of amino-modified silicone oil and long-chain alkyl group, which is applied in the directions of improved hand-feeling fibers, textiles and papermaking, fiber processing, etc., to achieve the effects of reducing surface tension, increasing waterproof performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

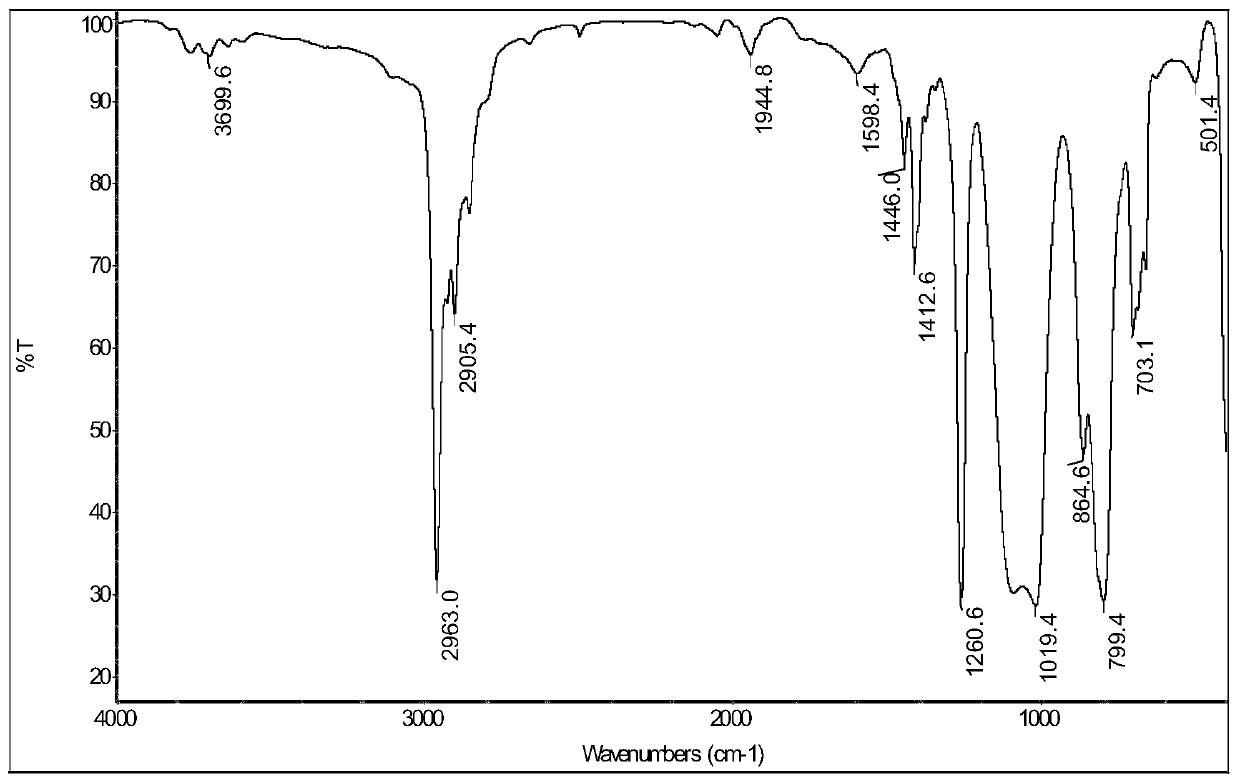

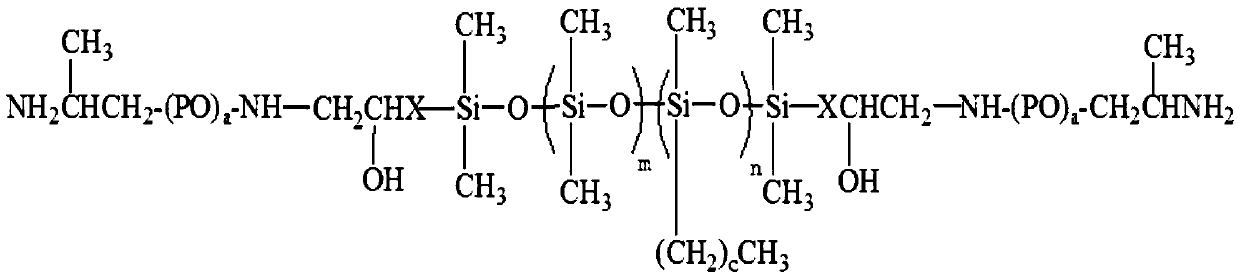

Image

Examples

Embodiment 1

[0034] (1) Preparation of amino-terminated silicone intermediate: Add 0.01mol of 1,3-bis(3-glycidylpropyl)-1,1,3,3-tetramethyldisiloxane to the reaction flask in sequence (molecular weight: 362.61), 0.015 mol of polyetheramine D220, and react at a temperature of 100° C. for 10 hours to obtain an amino-terminated organosilicon intermediate.

[0035] (2) Preparation of amino-modified silicone oil containing long-chain alkyl groups: sequentially add 2 g of the amino-terminated organosilicon intermediate obtained in step (1), 100 g of organosilicon monomer octamethylcyclotetrasiloxane, 2g of octaalkylmethyldimethoxysilane as a coupling agent, stir and heat up, add 0.05g of basic catalyst tetramethylammonium hydroxide at 60°C, continue to heat up to 100°C, react for 4 hours, then heat up to 145°C Carry out vacuum distillation to remove low boilers and catalysts to obtain amino-modified silicone oil containing long-chain alkyl groups.

Embodiment 2

[0037] (1) Preparation of amino-terminated silicone intermediate: Add 0.01mol of 1,3-bis(3-glycidylpropyl)-1,1,3,3-tetramethyldisiloxane to the reaction flask in sequence (molecular weight: 362.61), 0.02 mol of polyetheramine D230, and react at a temperature of 110° C. for 8 hours to obtain an amino-terminated organosilicon intermediate.

[0038] (2) Preparation of amino-modified silicone oil containing long-chain alkyl groups: sequentially add 4 g of the amino-terminated organosilicon intermediate obtained in step (1), 100 g of organosilicon monomer octamethylcyclotetrasiloxane, Coupling agent dodecylmethyldimethoxysilane 3g, stir and heat up, add basic catalyst potassium hydroxide 0.07g at 70°C, continue to heat up to 110°C, react for 5 hours, then heat up to 150°C to reduce Low boilers and catalysts are removed by pressure distillation to obtain amino-modified silicone oil containing long-chain alkyl groups.

Embodiment 3

[0040] (1) Preparation of amino-terminated silicone intermediate: Add 0.01mol of 1,3-bis(3-glycidylpropyl)-1,1,3,3-tetramethyldisiloxane to the reaction flask in sequence (Molecular weight: 362.61), 0.03 mol of polyetheramine D230, and react at a temperature of 90° C. for 4 hours to obtain an amino-terminated organosilicon intermediate.

[0041] (2) Preparation of amino-modified silicone oil containing long-chain alkyl groups: sequentially add 5 g of amino-terminated organosilicon intermediate obtained in step (1), 100 g of organosilicon monomer dimethylcyclosiloxane mixture, Coupling agent hexadecylmethyldimethoxysilane 3.5g, stir and heat up, add 0.1g of alkaline catalyst sodium hydroxide at 50°C, continue to heat up to 105°C, react for 3 hours, then heat up to 140°C Low boilers and catalysts were removed by distillation under reduced pressure to obtain amino-modified silicone oil containing long-chain alkyl groups.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com