Welding method for tube plate and header of steam generator of high temperature gas cooler reactor

A technology of steam generator and high temperature gas-cooled reactor, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of difficult welding of tube sheets and headers, perforated welding, and impervious welding, so as to avoid welding failure. Penetration, solving difficult welding, and meeting the effect of demanding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

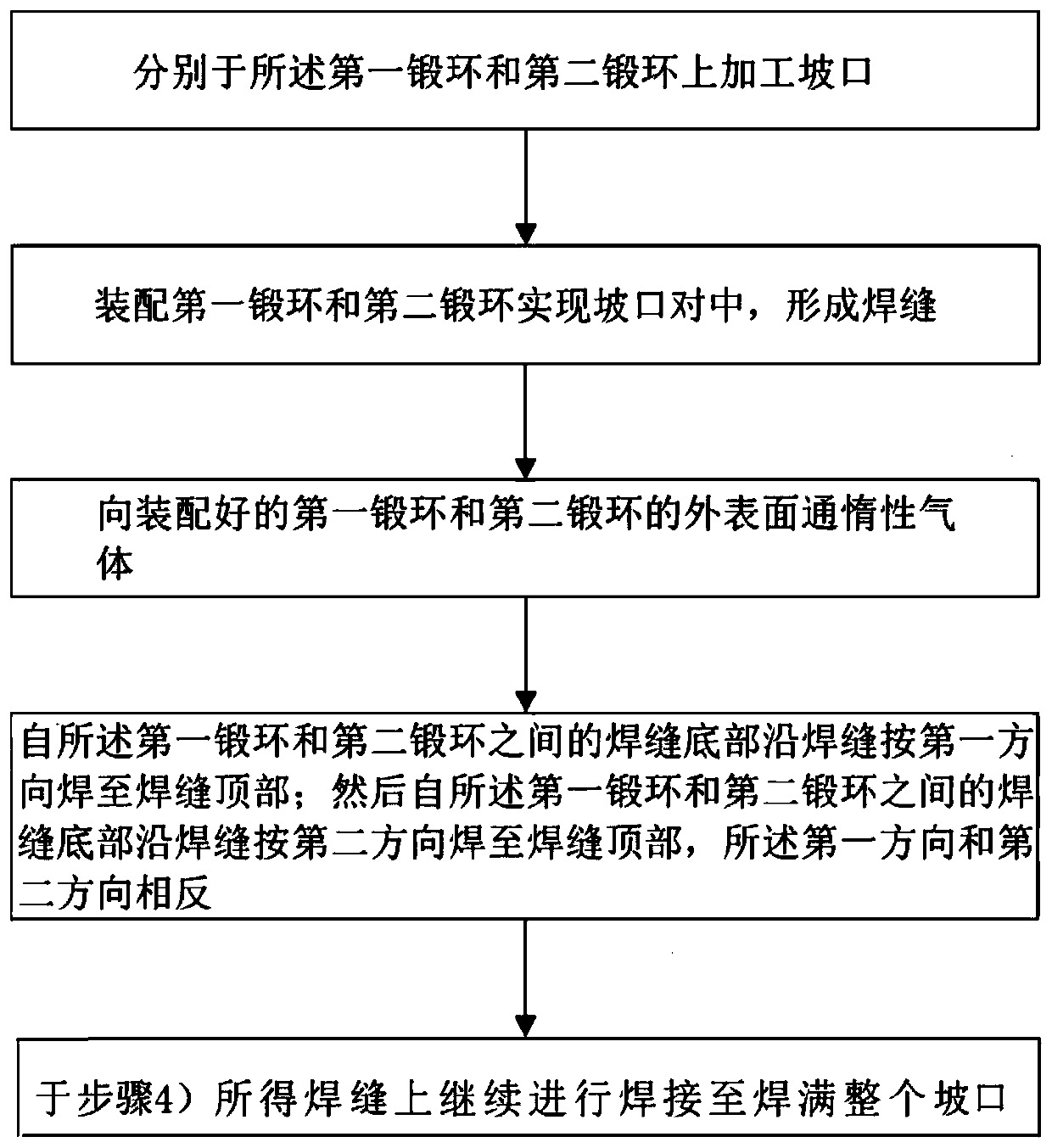

[0033] Such as figure 1 As shown, the welding method of the tube plate and the header of the high temperature gas-cooled reactor steam generator according to the embodiment of the present invention, the tube plate is the first forging ring, and the header is the second forging ring, including the following steps:

[0034] 1) processing grooves on the first forging ring and the second forging ring respectively;

[0035] 2) Assemble the first forging ring and the second forging ring to realize groove alignment and form a weld;

[0036] 3) passing an inert gas to the outer surfaces of the assembled first forged ring and the second forged ring;

[0037] 4) Weld from the bottom of the weld between the first forged ring and the second forged ring to the top of the weld along the weld in the first direction; then from the weld between the first forged ring and the second forged ring welding the bottom of the seam to the top of the seam in a second direction along the seam, the firs...

Embodiment 2

[0040] combine figure 2 and image 3 As shown, taking the 800H forged ring butt welding with a size of φ960×77.5×200mm as an example, the ERNiCr-7A welding wire with a size of 1.2mm is used for automatic argon tungsten arc welding. The specific process is as follows:

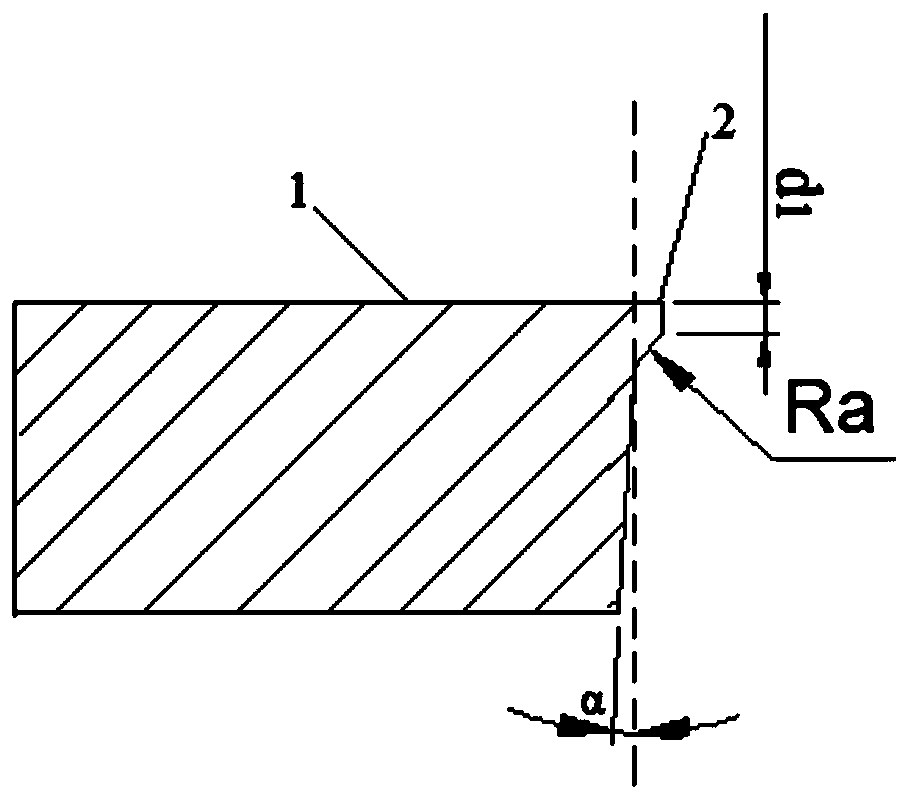

[0041] 1) Groove 2 is processed on two forging rings 1 respectively, and the blunt edge thickness of groove 2 is d 1The groove surface roughness Ra is 6.5, and the groove surface angle α is 3.5 degrees. During the machining process, the groove size of the two forging rings must be strictly guaranteed to ensure the subsequent assembly requirements;

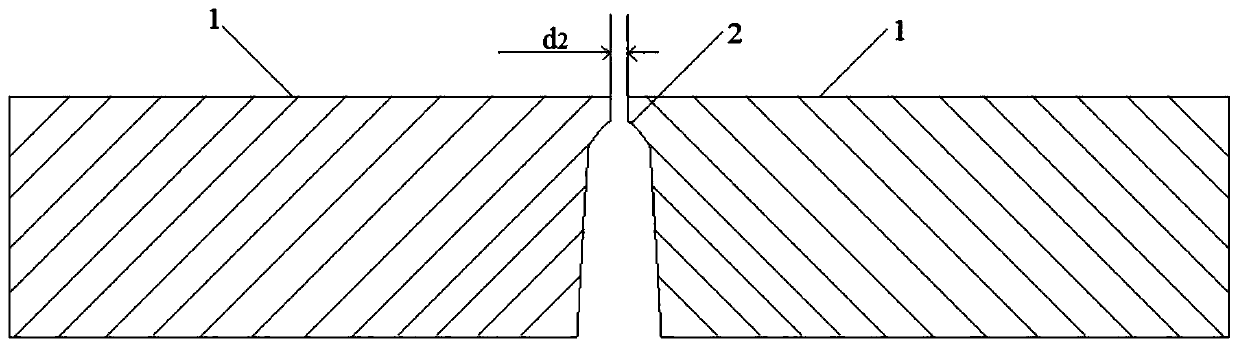

[0042] 2) Assemble the two forged rings with bevels, and the gap at the root after assembly is d 2 0.8mm, misalignment is 0.6mm;

[0043] 3) Pass argon gas on the outer surface of the assembled forging ring for 20 minutes to remove the air on the outer surface;

[0044] 4) According to the welding method parameters shown in Table 1, automatic welding of argon tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com