Preparation method of bio-based pentamethylene diisocyanate trimer

A technology based on pentamethylene diisocyanate and pentamethylene diisocyanate, applied in the field of preparation of bio-based pentamethylene diisocyanate trimer, can solve the influence of trimer stability, catalyst concentration sensitivity, three The viscosity of the polymer increases and other problems, so as to reduce the preparation cost, make the color transparent, and improve the bending resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

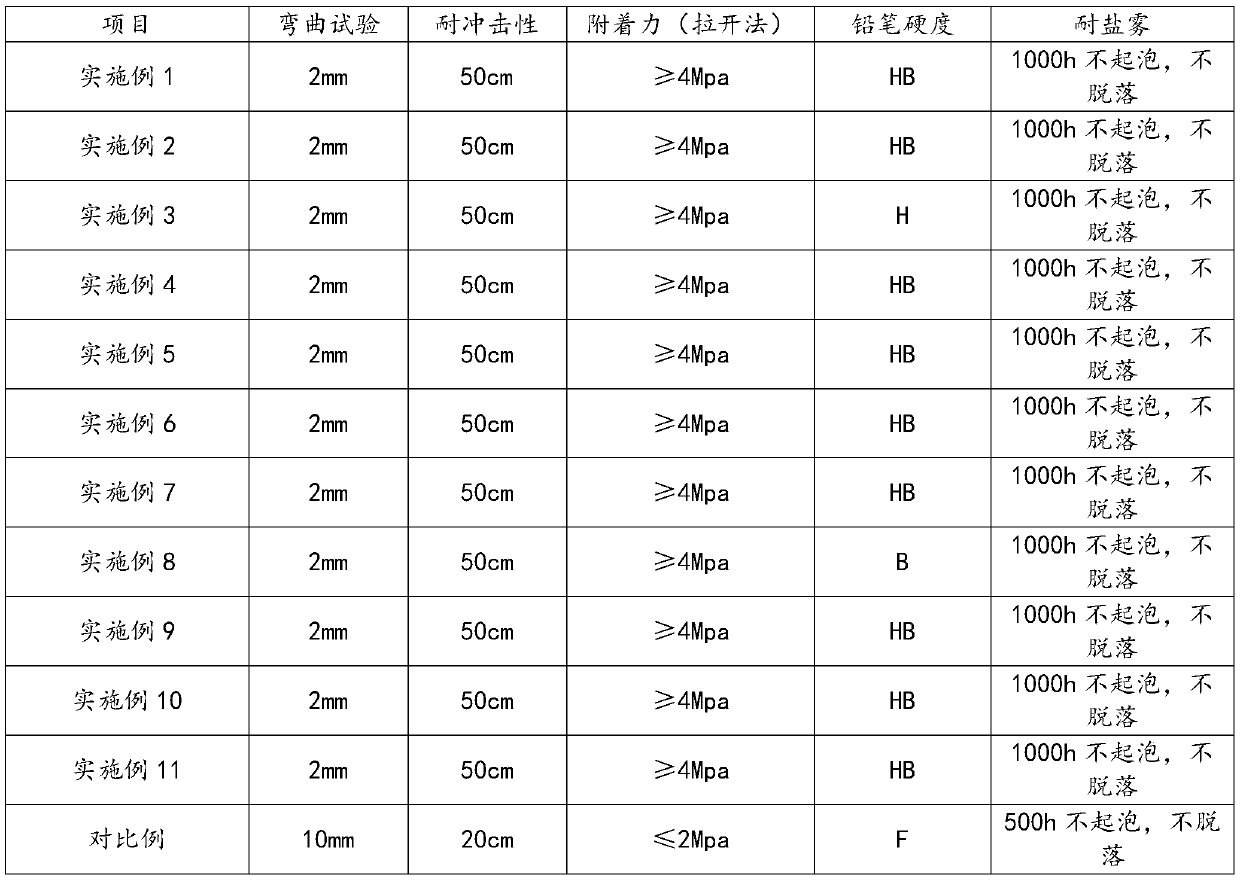

Examples

Embodiment 1

[0035] The preparation method of the bio-based pentamethylene diisocyanate trimer of the present embodiment comprises the following steps:

[0036] 1) Take the crude product of pentamethylene diisocyanate monomer (PDI) (Gansu Yinguang) and carry out inert atmosphere purging, the purity of the crude product of PDI is ≥ 98%, the mass fraction of isocyanate is ≥ 50%, the chromaticity ≤ APHA40, insoluble ≤1wt%, specifically: get 300 parts by mass of PDI crude product, add 0.5 parts by mass of tri(dodecyl) phosphite, shake to fully disperse, then pass into nitrogen purging, the flow rate of purging gas is 40ml / min, the purging temperature is 220°C, and the purging time is 2h. After purging, take out the PDI sample and carry out distillation operation. The temperature at the bottom of the distillation tower is 180°C, and the distillation time is 1h. The light fraction is collected as PDI For the fine product, add 0.2 parts by mass of tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)pro...

Embodiment 2

[0041] The preparation method of the bio-based pentamethylene diisocyanate trimer of the present embodiment comprises the following steps:

[0042] 1) Take the PDI crude product and carry out inert atmosphere purging, specifically: take 300 mass parts of the PDI crude product, add 0.5 mass parts of tris(dodecyl) phosphite, shake to fully disperse, and then pass nitrogen gas to purify , the flow rate of the purge gas is 55ml / min, the purge temperature is 230°C, and the purge time is 2h. The monomer is distilled off, the distillation is stopped, and the PDI fine product is obtained, and 0.2 parts by mass of tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythyl ester is added for stable storage. use;

[0043] 2) Take 300 parts by mass of PDI high-quality goods, add 0.2 parts by mass of antioxidant tetrakis [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentapentyl alcohol ester, add catalyst A three (2 , 0.2 parts by mass of 4-di-tert-butylphenyl)phosphi...

Embodiment 3

[0046] The preparation method of the bio-based pentamethylene diisocyanate trimer of the present embodiment comprises the following steps:

[0047] 1) Take the PDI crude product and carry out inert atmosphere purging, specifically: take 300 mass parts of the PDI crude product, add 2 mass parts of tris (dodecyl) phosphite, shake to fully disperse, pass into nitrogen purging, The flow rate of the purge gas is 40ml / min, the purge temperature is 220°C, and the purge time is 1h. After the purge is completed, the PDI sample is taken out and subjected to vacuum distillation. The distillation temperature is 165°C, and the distillation pressure is 15mbar. The monomer was distilled out, and after the monomer was taken out, the vacuum distillation was carried out again. The above-mentioned vacuum distillation was repeated 3 times, and the vacuum distillation operation was stopped to obtain the fine PDI. Add 0.2 parts by mass of tetrakis [3-(3,5-di tert-butyl-4-hydroxyphenyl) propionate] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com