Thorium extraction and separation method

A separation method and extraction technology, which is applied in the field of extraction and separation of thorium, can solve the problems that the primary amine N1923 cannot be directly used to treat the radioactive waste residue of ionic rare earth mines, and the leaching rate is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

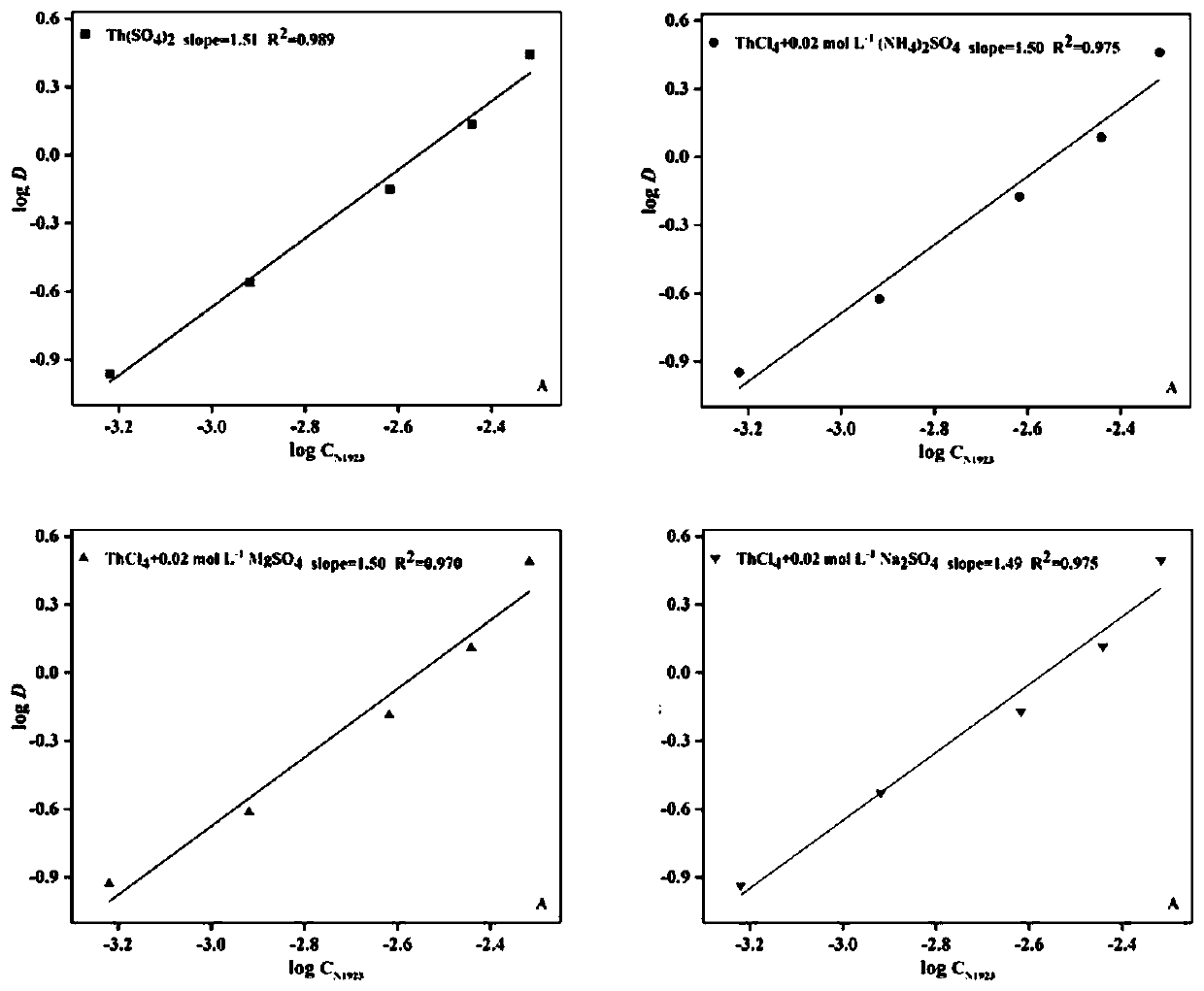

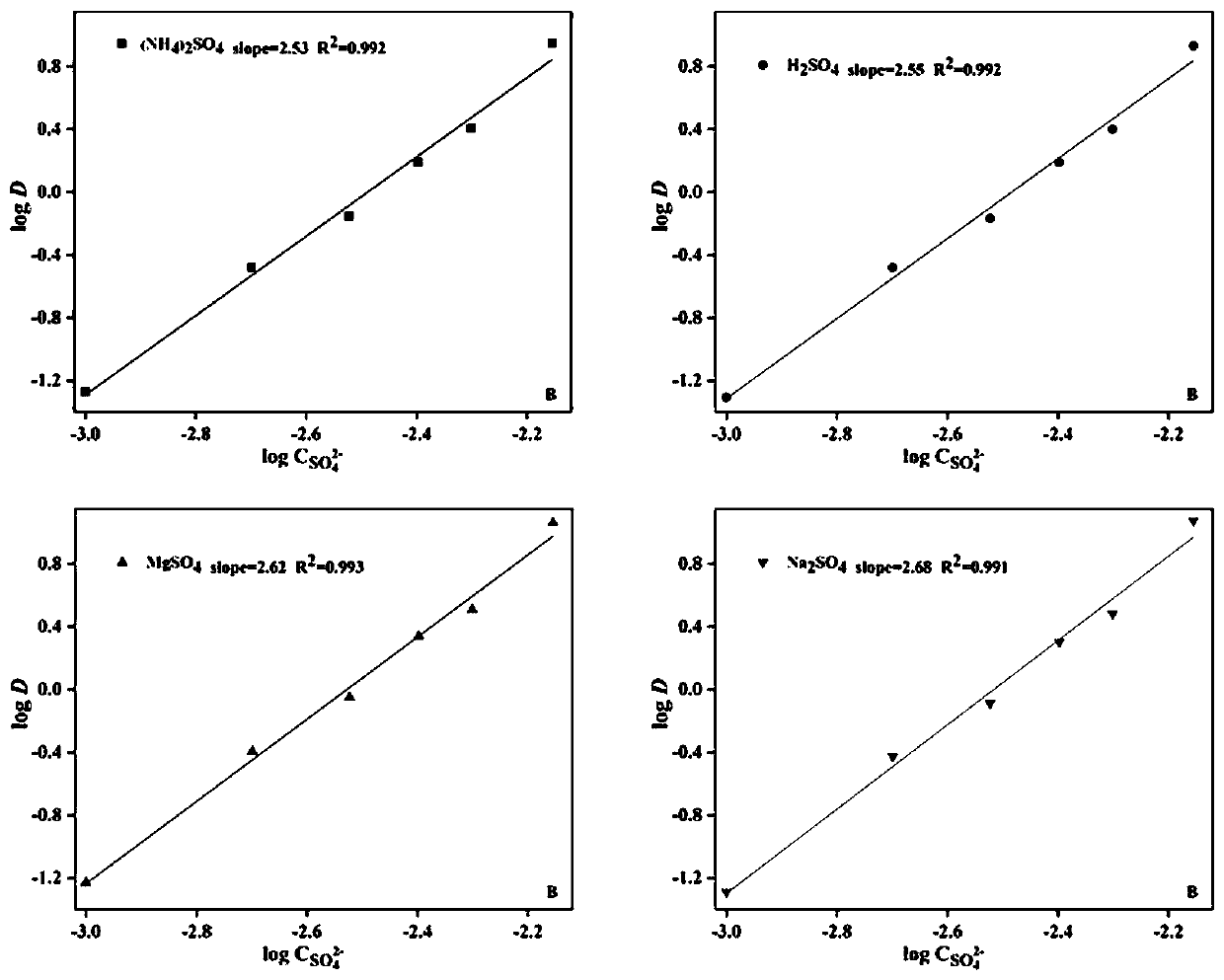

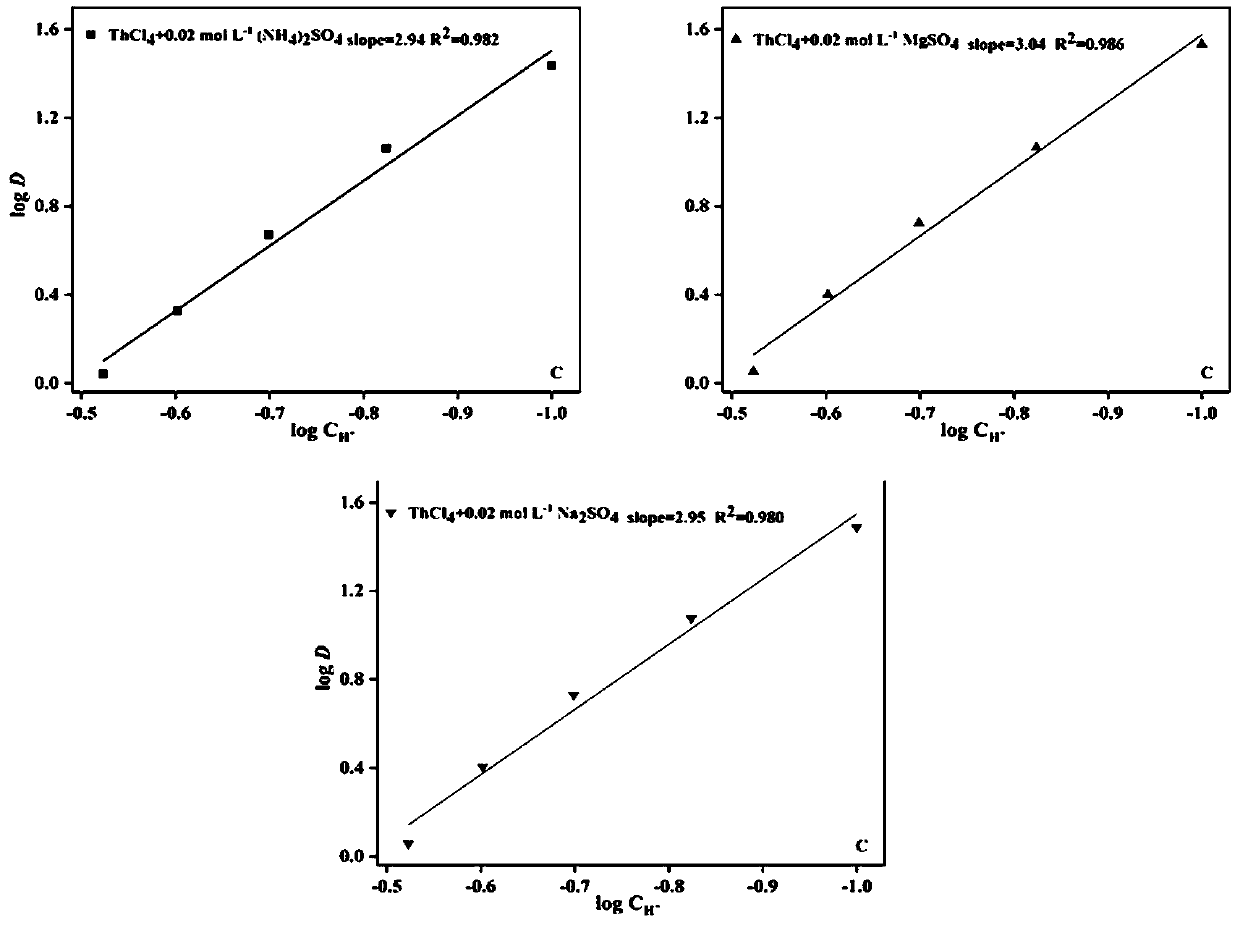

Method used

Image

Examples

Embodiment 1

[0069] Adoption includes rare earth concentration C RE 8.97mmol / L, thorium ion concentration C Th 0.56mmol / L, sulfate concentration 0.01mol / L chloride salt solution; the concentration of N1923 in the extractant C N1923 4mmol / L; when the pH value of the leach solution is 1.50, after the extraction is completed, the extraction rate of thorium ions is 96.87%, the extraction rate of rare earth is less than 0.01%, and the separation factor is greater than 10 6 .

Embodiment 2

[0071] Adoption includes rare earth concentration C RE 8.97mmol / L, thorium ion concentration C Th 0.56mmol / L, sulfuric acid concentration 0.025mol / L chloride salt solution; the concentration of N1923 in the extractant C N1923 When the pH value of the leach solution is 1.50, after the extraction is completed, the extraction rate of thorium ions is 99.55%, the extraction rate of rare earth is 0.08%, and the separation factor is 278095.

Embodiment 3

[0073] Adoption includes rare earth concentration C RE 8.97mmol / L, thorium ion concentration C Th is 0.56mmol / L, in the chlorine salt solution of sulfate radical concentration 0.02 mol / L; the concentration C of N1923 in the extractant N1923 It is 5.43mmol / L; when the pH value of the leachate is 1.00, after the extraction is completed, the extraction rate of thorium ions is 95.78%, the extraction rate of rare earth is 0.05%, and the separation factor is 49097; when the pH value of the leachate is 1.50, the extraction is complete Finally, the extraction rate of thorium ions was 99.42%, the extraction rate of rare earths was 0.09%, and the separation factor was 183374; when the pH value of the leach solution was 2.0, after the extraction was completed, the extraction rate of thorium ions was 99.21%, and the extraction rate of rare earths was 99.21%. 0.10%, with a separation factor of 131368.

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com