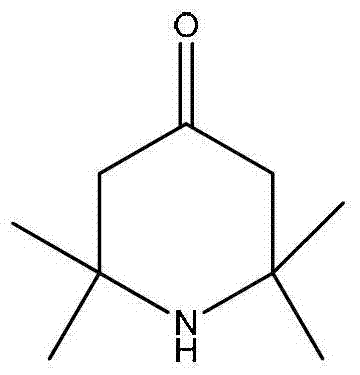

2,2,6,6,-tetramethyl-4-piperidone continuous synthesis method

A synthesis method and piperidone technology are applied in the field of synthesis of 2,2,6,6-tetramethyl-4-piperidone, and can solve the problems of increased production cost, reduced selectivity, easy inactivation and the like, Achieve the effect of avoiding pollution, low cost and improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

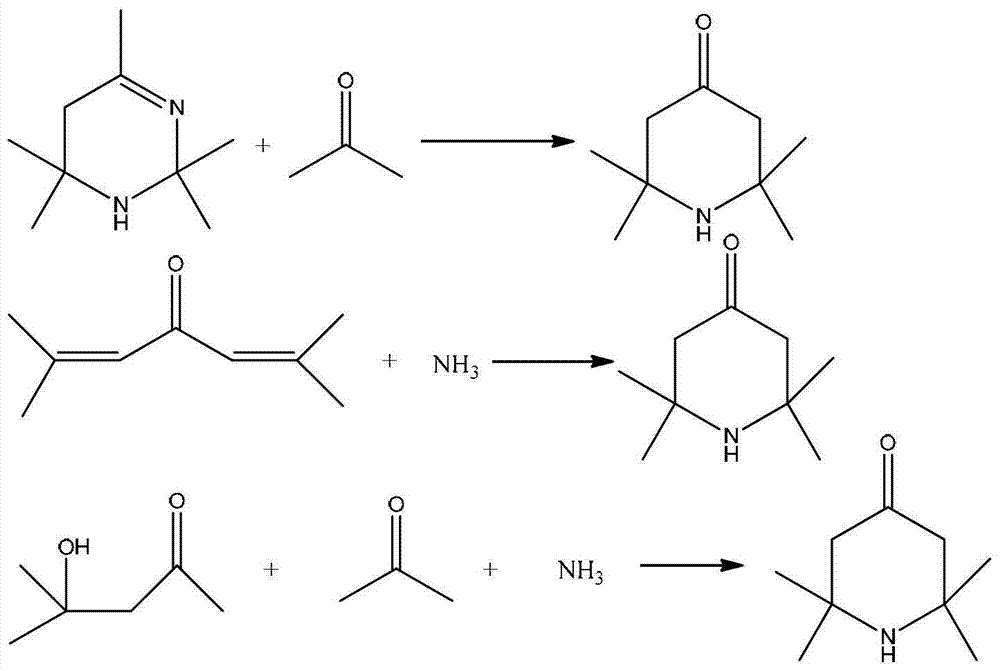

Method used

Image

Examples

Embodiment 1

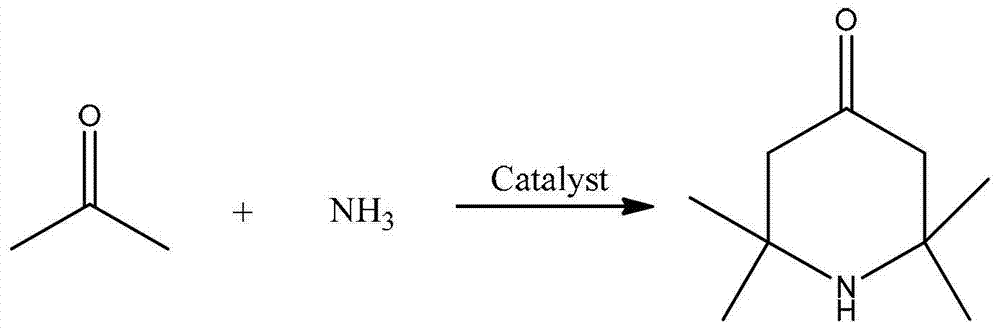

[0024] A kind of 2,2,6,6-tetramethyl-4-piperidone continuous synthesis method, comprises the steps:

[0025] (1) The reactor is a fixed-bed single-tubular reactor with an inner diameter of 14mm and a tube length of 650mm. It is filled with 40mL of sulfonic acid resin D061, and heated to keep the temperature of the fixed-bed single-tubular reactor at 60°C;

[0026] (2) Acetone and ammonia gas are passed into the reactor from the upper end of the fixed-bed single-tubular reactor through the preheater according to the molar ratio of 6:1, and the volume space velocity of acetone is 0.39h -1 , the volumetric space velocity of ammonia gas is 20.7h -1 ;

[0027] (3) The reaction product flows out from the lower end of the fixed-bed single-tubular reactor, and the effluent is cooled and gas-liquid separated to obtain the crude product of 2,2,6,6-tetramethyl-4-piperidone. After gas chromatography analysis, the selectivity was 65%.

Embodiment 2

[0029] A kind of 2,2,6,6-tetramethyl-4-piperidone continuous synthesis method, comprises the steps:

[0030] (1) The reactor is a fixed-bed single-tubular reactor with an inner diameter of 14mm and a tube length of 650mm. It is filled with 40mL of sulfonic acid resin D072 and heated to keep the temperature of the fixed-bed single-tubular reactor at 50°C;

[0031] (2) Pass acetone and ammonia gas into the reactor from the upper end of the fixed-bed single-tubular reactor through the preheater according to the molar ratio of 9:1, and the volumetric space velocity of acetone is 0.15h -1 , the volumetric space velocity of ammonia gas is 5.25h -1 ;

[0032] (3) The reaction product flows out from the lower end of the fixed-bed single-tubular reactor, and the effluent is cooled and gas-liquid separated to obtain the crude product of 2,2,6,6-tetramethyl-4-piperidone. After gas chromatography analysis, the selectivity was 60%.

Embodiment 3

[0034] A kind of 2,2,6,6-tetramethyl-4-piperidone continuous synthesis method, comprises the steps:

[0035] (1) The reactor is a fixed-bed tubular reactor with an inner diameter of 14 mm and a tube length of 650 mm. It is filled with 40 mL of sulfonic acid resin NKC-9, and heated to keep the temperature of the fixed-bed single-tubular reactor at 70 ° C;

[0036] (2) Pass acetone and ammonia gas into the reactor from the upper end of the fixed-bed single-tubular reactor through the preheater according to the molar ratio of 3:1, and the volume space velocity of acetone is 1.17h -1 , the volume space velocity of ammonia gas is 124.2h -1 ;

[0037] (3) The reaction product flows out from the lower end of the fixed-bed single-tubular reactor, and the effluent is cooled and gas-liquid separated to obtain a crude 2,2,6,6-tetramethyl-4-piperidone as a liquid. After gas chromatography analysis, the selectivity was 54%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com