Biomass particle furnace combustor capable of automatically removing coke

A biomass particle and burner technology, applied in the field of combustion furnaces, can solve the problems of low thermal efficiency, insufficient fuel combustion, manual cleaning, etc., achieve high thermal efficiency, sufficient fuel combustion, and solve the effects of fuel coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

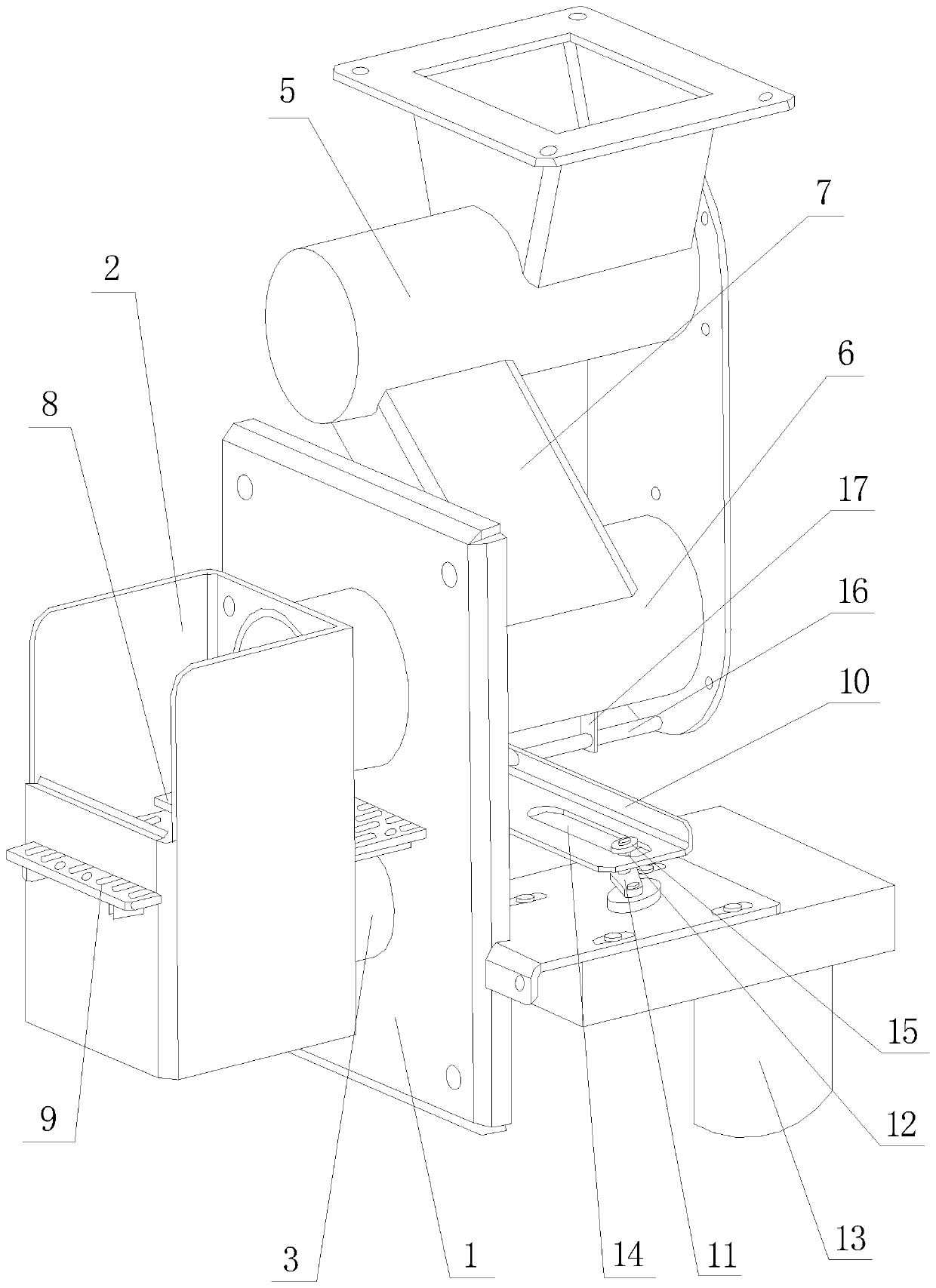

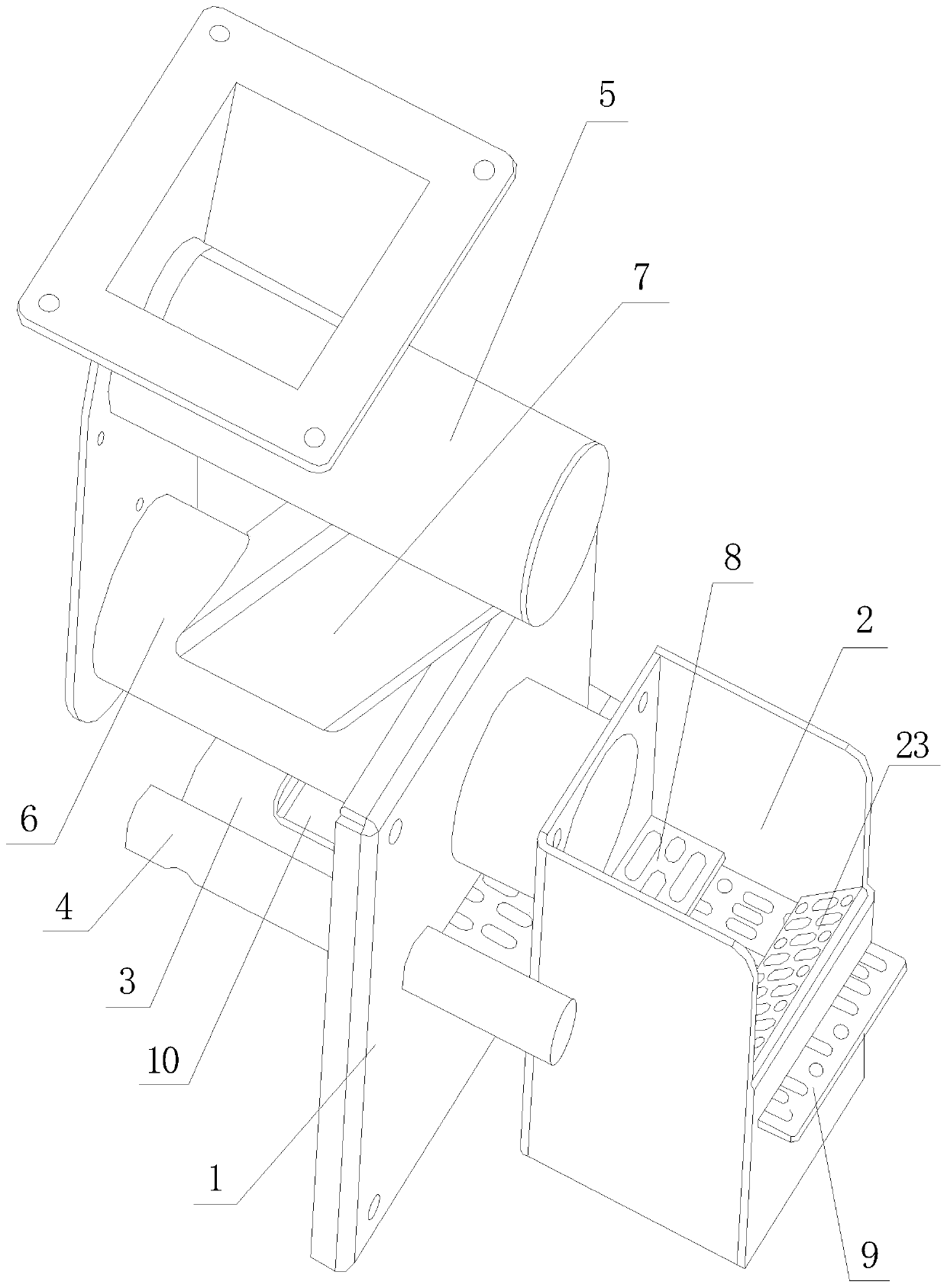

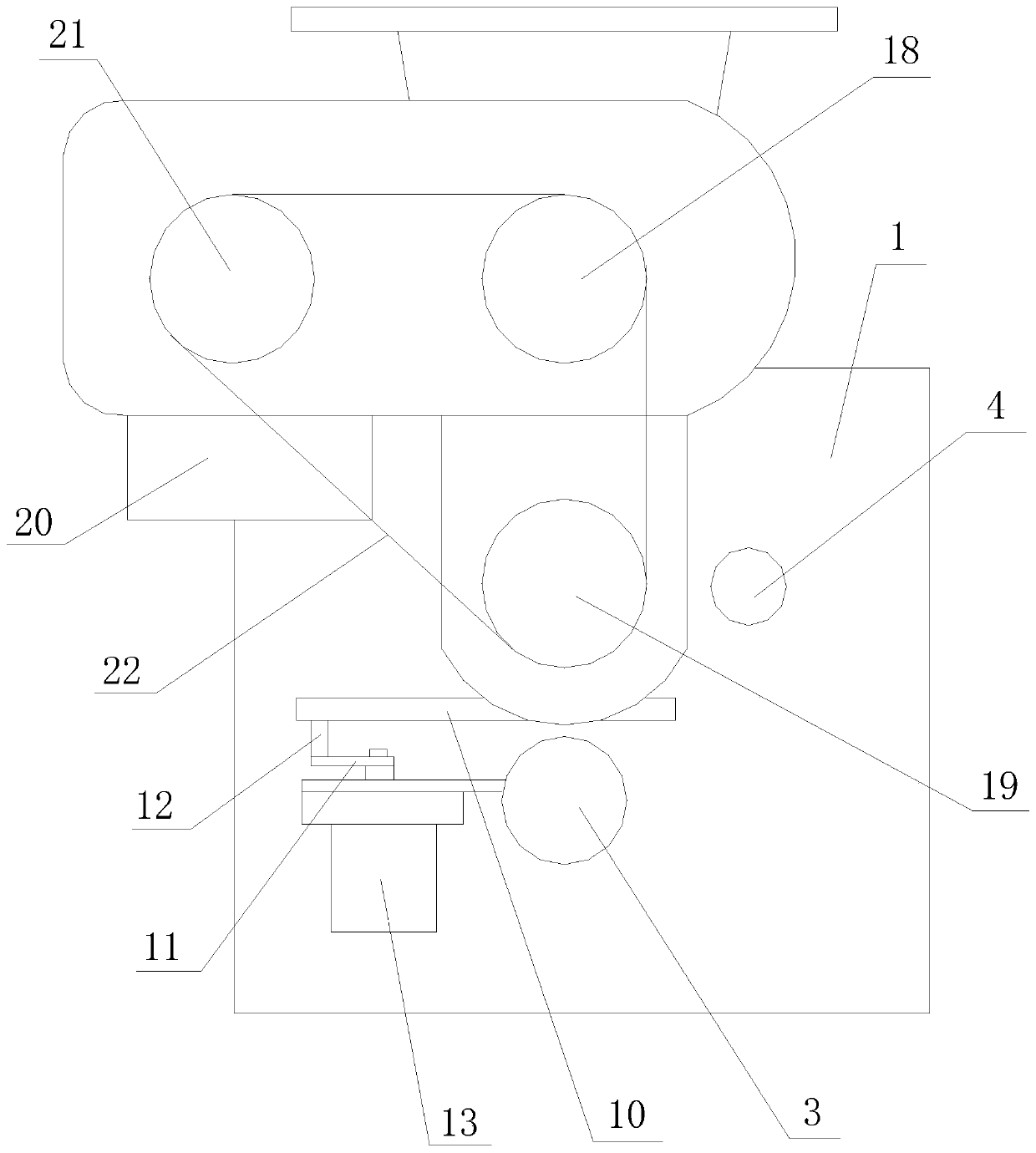

[0018] Reference Figure 1-Figure 2 , The biomass pellet stove burner capable of automatically decoking described in this embodiment includes a fixed plate 1, a feeding mechanism, a combustion chamber 2, a blast tube 3, and an ignition for fixing the burner on the furnace body. 器装管4。 Device installation pipe 4. among them:

[0019] The feeding mechanism includes a first feeding auger 5, a second feeding auger 6, and a feeding driving device that drives the first feeding auger 5 and the second feeding auger 6 to rotate the feed. The second feed auger 6 is arranged below the first feed auger 5, and its feed port is communicated with the discharge port of the first feed auger 5 through a feed pipe 7, and its discharge port is connected to the combustion chamber. 2 Connected.

[0020] A fixed grate 8 is provided on the rear side wall of the combustion chamber 2, and the fixed grate 8 is fixedly assembled under the discharge port of the second feed auger 6. A mobile grate 9 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com