Preparation method of lithium phosphate coated lithium-ion battery ternary positive electrode material

A technology for lithium-ion batteries and positive electrode materials, which is applied in the direction of battery electrodes, positive electrodes, electrical components, etc., can solve the problems of easily bringing water into the battery, poor material cycle performance, and poor material storage performance, so as to avoid water and Carbon dioxide exposure, small effect on specific capacity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

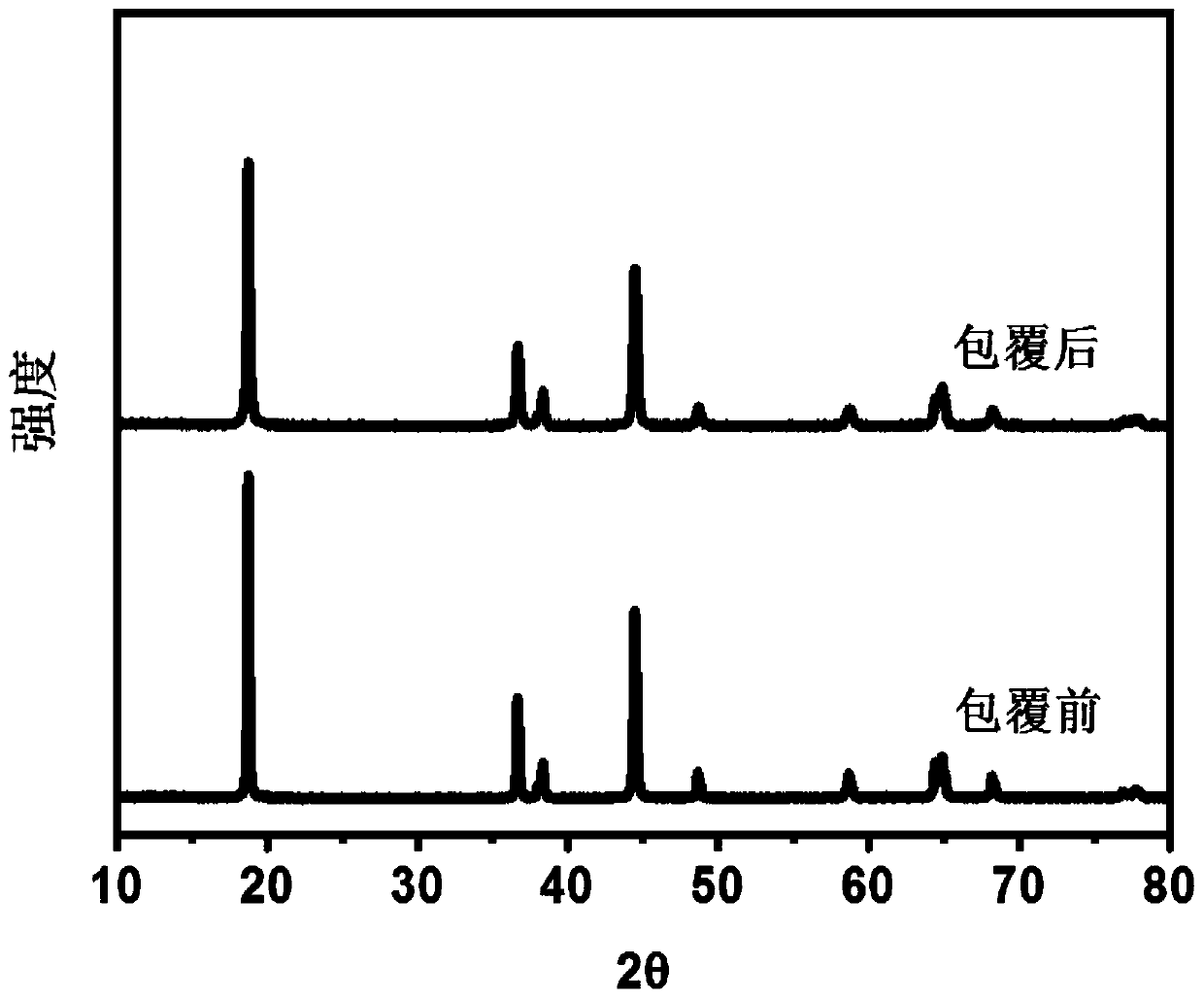

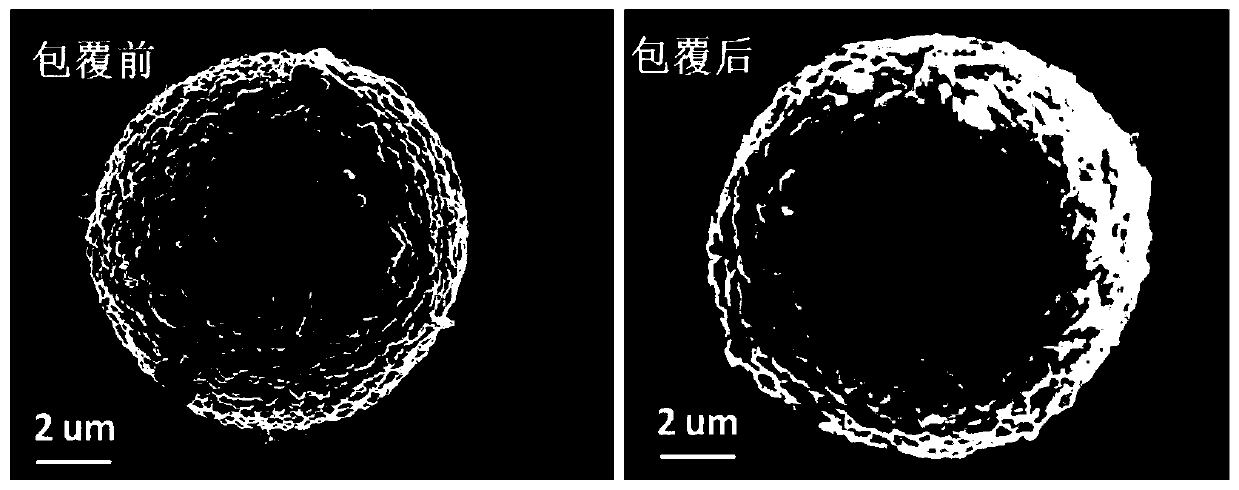

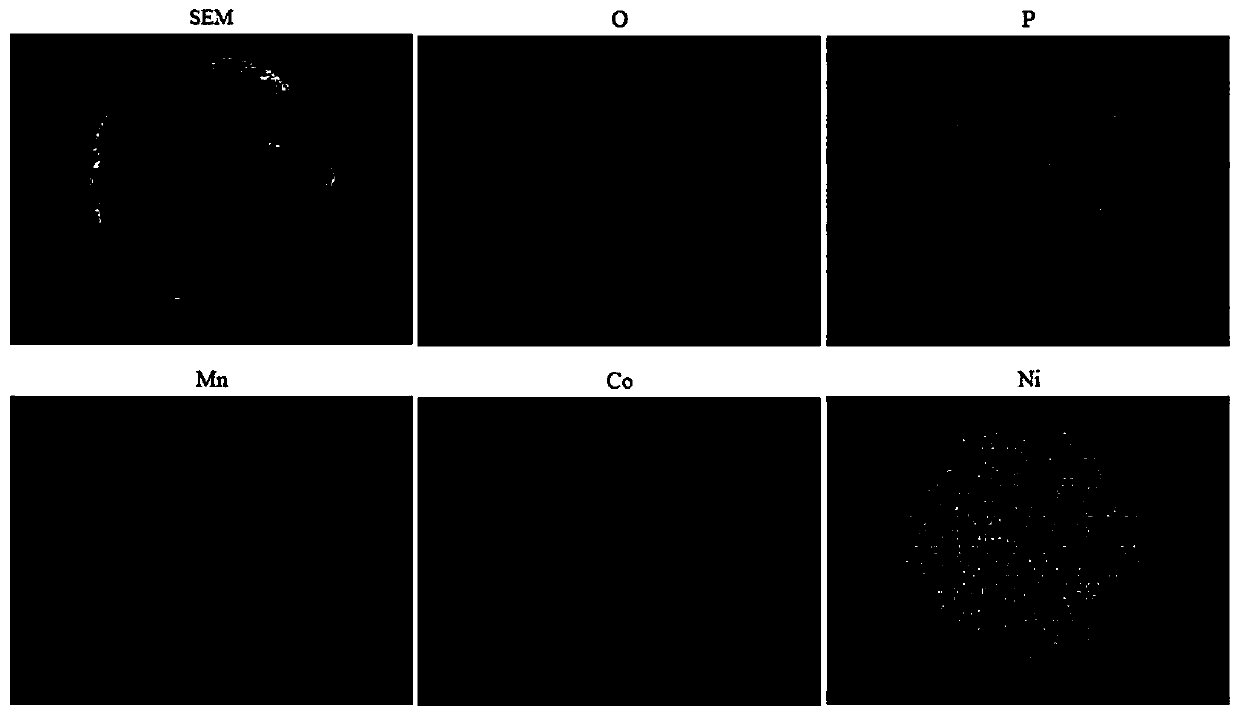

Embodiment 1

[0031] Dissolving polyphosphoric acid in 60g dimethyl sulfoxide is configured into a polyphosphoric acid solution with a mass fraction of 0.4%, adding 10g LiNi 0.8 co 0.1 mn 0.1 o 2 Stir the material for 30 minutes to disperse it evenly, and evaporate dimethyl sulfoxide to dryness at 140° C. to obtain a lithium phosphate-coated ternary cathode material. For its physical and chemical properties, see figure 1 , figure 2 , image 3 . XRD shows that the obtained product has high crystallinity, and LiNi after lithium phosphate coating 0.8 co 0.1 mn 0.1 o 2 The structure of the material does not change. Due to the small amount of lithium phosphate coating, the peak of lithium phosphate is not detected. The SEM image shows that LiNi before and after coating 0.8 co 0.1 mn 0.1 o 2 The morphology of the material does not change significantly. It can be seen from the EDS scanning image of the phosphorus element that the phosphorus element is uniformly dispersed in LiNi 0.8...

Embodiment 2

[0033] Dissolve a certain amount of pyrophosphoric acid in 10g N,N-dimethylformamide to form a polyphosphoric acid solution with a mass fraction of 0.8%, add 10g LiNi 0.6 co 0.2 mn 0.2 o 2 Stir the material for 30 minutes to disperse evenly, and evaporate N,N-dimethylformamide to dryness at 140°C to obtain lithium phosphate-coated LiNi 0.6 co 0.2 mn 0.2 o 2 Material. Its XRD characterization shows that the obtained product has high crystallinity, and LiNi after lithium phosphate coating 0.6 co 0.2 mn 0.2 o 2 Material structure does not change, can refer to in embodiment 1 figure 1 , SEM images show LiNi before and after lithium phosphate coating 0.6 co 0.2 mn 0.2 o 2 The material morphology does not change significantly, with reference to the figure 2 . The resulting product was assembled into a button battery to test its charge and discharge capacity and rate performance at 25°C. Charge and discharge were performed at different rates. LiNi before and after li...

Embodiment 3

[0035] Dissolve a certain amount of polyphosphoric acid in 100g dimethyl sulfoxide to prepare polyphosphoric acid solutions with mass fractions of 0.05%, 0.2%, and 0.8%, respectively, and add 10g LiNi 0.8 co 0.1 mn 0.1 o 2 Stir the material for 30 minutes to disperse evenly, and evaporate dimethyl sulfoxide to dryness at 140°C to obtain lithium phosphate-coated LiNi 0.8 co 0.1 mn 0.1 o 2 Material. Take the above materials and uncoated LiNi respectively 0.8 co 0.1 mn 0.1 o 2 The material was mixed with deionized water at a liquid-solid ratio of 10:1, sealed, stirred for 2 minutes and then left to stand for 30 minutes to test the pH of the solution. The results are shown in Table 1. It can be seen from the pH that after adding the polyphosphoric acid solution, the lithium residue (lithium oxide, lithium hydroxide) on the surface of the material is converted into lithium phosphate, and the lithium residue on the surface of the ternary positive electrode material can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com