Harengula zunasi glycoprotein extracting method and application

An extraction method, the technology of meadow carp, is applied in the field of biochemistry to achieve the effects of ensuring activity, increasing extraction rate, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for extracting medlar glycoprotein, comprising the following steps:

[0037] ①Pretreatment: Clean the scales of the fresh medaka, drain the water, cut the fish meat into pieces, and grind them in a meat grinder to obtain the medaka puree, which is weighed;

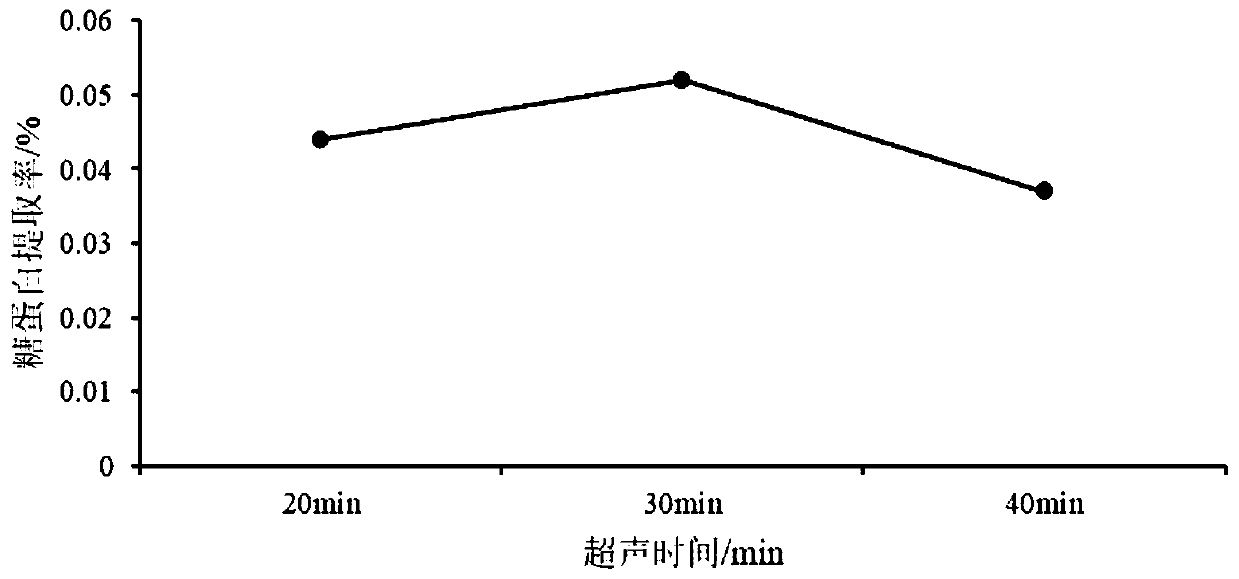

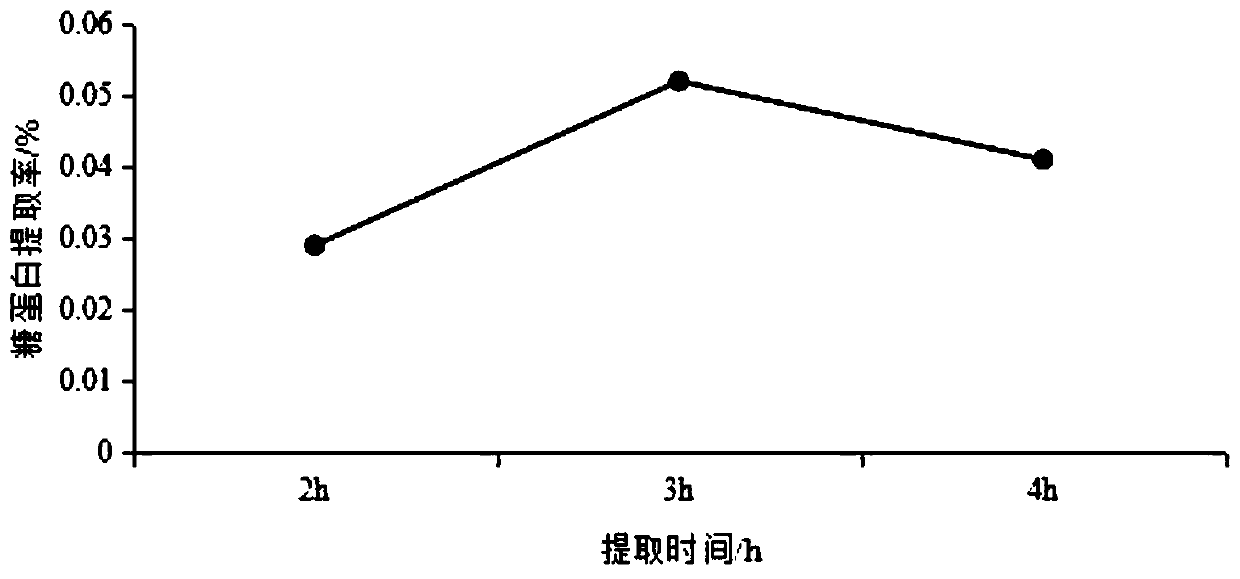

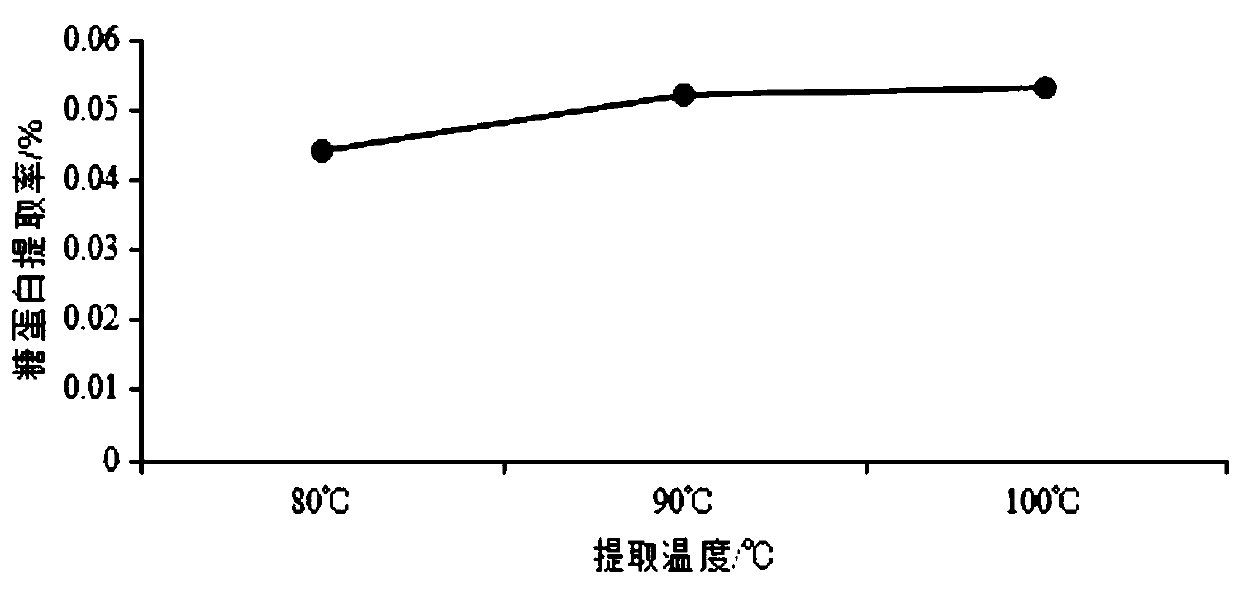

[0038] ②Ultrasonic treatment + hot water leaching: Mix the medlar meat paste obtained in step ① with distilled water at a material-to-liquid ratio of 1:20 (g / mL), and perform ultrasonic treatment for 30 minutes to obtain the medlar mixture and put it in a water bath. Extract in hot water at 100°C for 3 hours, filter, and use the obtained filtrate for later use. Mix the obtained filter residue with distilled water at a solid-liquid ratio of 1:20 (g / mL) and ultrasonically treat it for 30 minutes, then extract in hot water at 100°C for 1 hour, and filter , combining the filtrates twice to obtain the medlar glycoprotein mixed solution;

[0039] ③ Concentrated alcohol precipitation: Add the mixed solution obtai...

Embodiment 2

[0045] The operation steps of embodiment 2 and embodiment 1 are basically the same, and its difference is:

[0046] In the step ② ultrasonic treatment + hot water leaching: mix the medlar meat paste obtained in step ① with distilled water at a material-to-liquid ratio of 1:30 (g / mL), and ultrasonically treat it at 25°C for 40 minutes to obtain the medlar The mixture was placed in a water bath, leached with hot water at 90°C for 2 hours, filtered, and the obtained filtrate was used for later use. The obtained filter residue was mixed with distilled water at a material-liquid ratio of 1:30 (g / mL), then ultrasonically treated for 40 minutes, and then heated at 90°C Water leaching for 1 hour, filtering, and combining the two filtrates to obtain a medlar glycoprotein mixed solution;

[0047] Step ③ concentrated alcohol precipitation: put the mixed solution obtained in step ② into a rotary evaporator, evaporate and concentrate at 60°C to 1 / 5 of the original volume, add 3 times the v...

Embodiment 3

[0050] The operation steps of embodiment 3 and embodiment 1 are basically the same, and its difference is:

[0051] In the step ② ultrasonic treatment + hot water leaching: mix the medlar meat paste obtained in step ① with distilled water at a material-to-liquid ratio of 1:40 (g / mL), and ultrasonically treat it for 20 minutes at 30°C to obtain the medaka The fish mixture was placed in a water bath, leached in hot water at 80°C for 4 hours, filtered, and the obtained filtrate was used for later use. The obtained filter residue was mixed with distilled water at a solid-liquid ratio of 1:40 (g / mL), then ultrasonically treated for 20 minutes, and then heated at 80°C Hot water leaching for 1 hour, filtering, and combining the two filtrates to obtain a mixed solution of medlar glycoprotein;

[0052] Step ③ concentrated alcohol precipitation: put the mixed solution obtained in step ② into a rotary evaporator, evaporate and concentrate at 70°C to 1 / 5 of the original volume, add 3 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com