Method for removing poly-Si winding plating for manufacturing Topcon battery

A battery and winding plating technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problems of affecting the conversion efficiency of the battery terminal, poor battery appearance, and reduced passivation characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

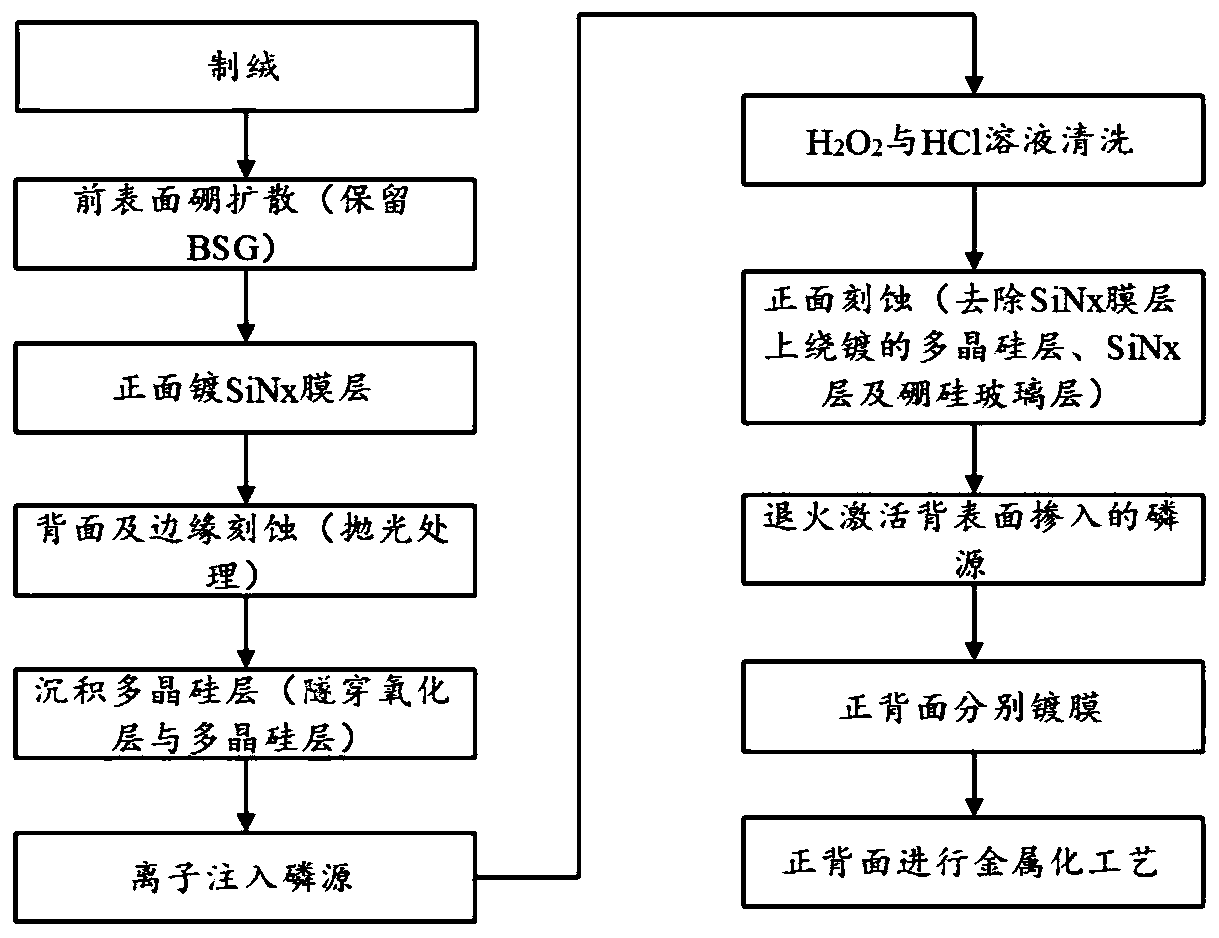

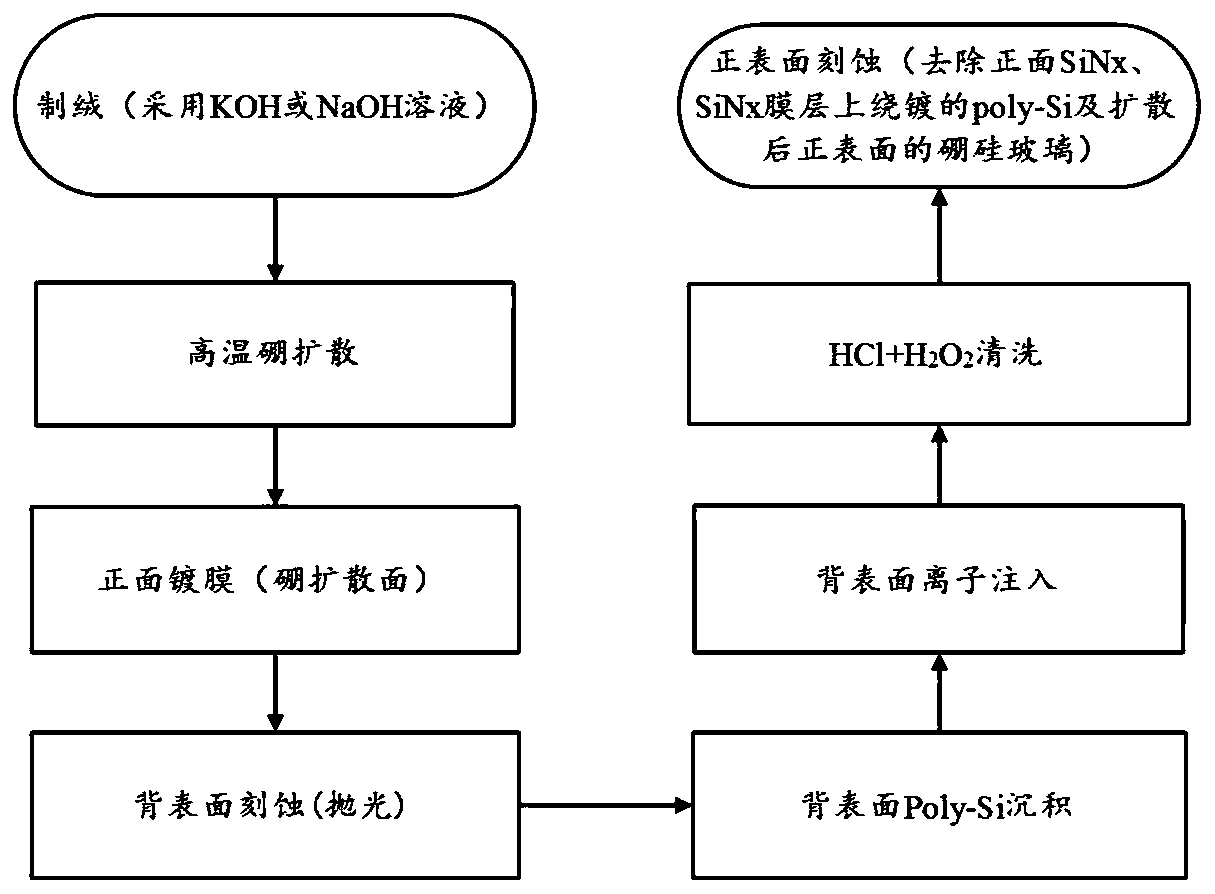

[0039] attached figure 2 For the process flow diagram of the N-type TOPCon battery poly-Si winding and plating removal provided by the implementation case of the present invention, refer to the attached figure 2 process flow chart,

[0040] Step 1: Invade the original silicon wafer at a temperature of 60°C with a mass fraction of 1% KOH and 1% H by using a conventional texturing process. 2 o 2 Remove the damaged layer in the mixed solution, and then use the mixed solution of KOH solution with a mass fraction of 1% and isopropanol with a volume fraction of 3% to perform double-sided texturing;

[0041] Step 2: Load the textured (textured) silicon wafer obtained after double-sided texturing into the tubular low-pressure boron diffusion furnace tube, and then complete the boron diffusion doping process on the front surface at a high temperature of 900°C for 15 minutes. After the doping process is completed, the BSG (borosilicate glass) layer on the front surface is retained;...

Embodiment 2

[0053] The method for removing the poly-Si wrap-around plating used for Topcon cell production comprises the following steps:

[0054] Step 1: Invade the original silicon wafer at a temperature of 73°C with a mass fraction of 3% KOH and a mass fraction of 3.5% H using a conventional texturing process. 2 o 2 Remove the damaged layer in the mixed solution, and then use the mixed solution of KOH solution with a mass fraction of 2% and isopropanol with a volume fraction of 4.5% to carry out double-sided texturing, and the control time for texturing is 25 minutes;

[0055] Step 2: Load the textured silicon wafer obtained after double-sided texturing into the tubular low-pressure boron diffusion furnace tube, and complete the front surface boron diffusion doping process at a high temperature of 930°C for 18 minutes. After the diffusion doping process is completed Retain the borosilicate glass layer on the front surface;

[0056] Step 3, use PECVD equipment for the front coating pr...

Embodiment 3

[0068] The method for removing the poly-Si wrap-around plating used for Topcon cell production comprises the following steps:

[0069]Step 1: Invade the original silicon wafer at a temperature of 85°C with a mass fraction of 5% KOH and a mass fraction of 6% H using a conventional texturing process. 2 o 2 Remove the damaged layer in the mixed solution, and then use the mixed solution of NaOH solution with a mass fraction of 3% and isopropanol with a volume fraction of 6% to carry out double-sided texturing, and the control time for texturing is 30 minutes;

[0070] Step 2: Load the textured silicon wafer obtained after double-sided texturing into the tubular low-pressure boron diffusion furnace tube, and complete the front surface boron diffusion doping process at a high temperature of 960°C for 20 minutes. After the diffusion doping process is completed Retain the borosilicate glass layer on the front surface;

[0071] Step 3, use PECVD equipment for the front coating proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com