Medicated candy produced based on 3D printing mold

A 3D printing and candy technology, applied in confectionery, confectionary industry, food science, etc., can solve the problems that there are no reports of medicated candy, and achieve the effect of adjustable drug release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

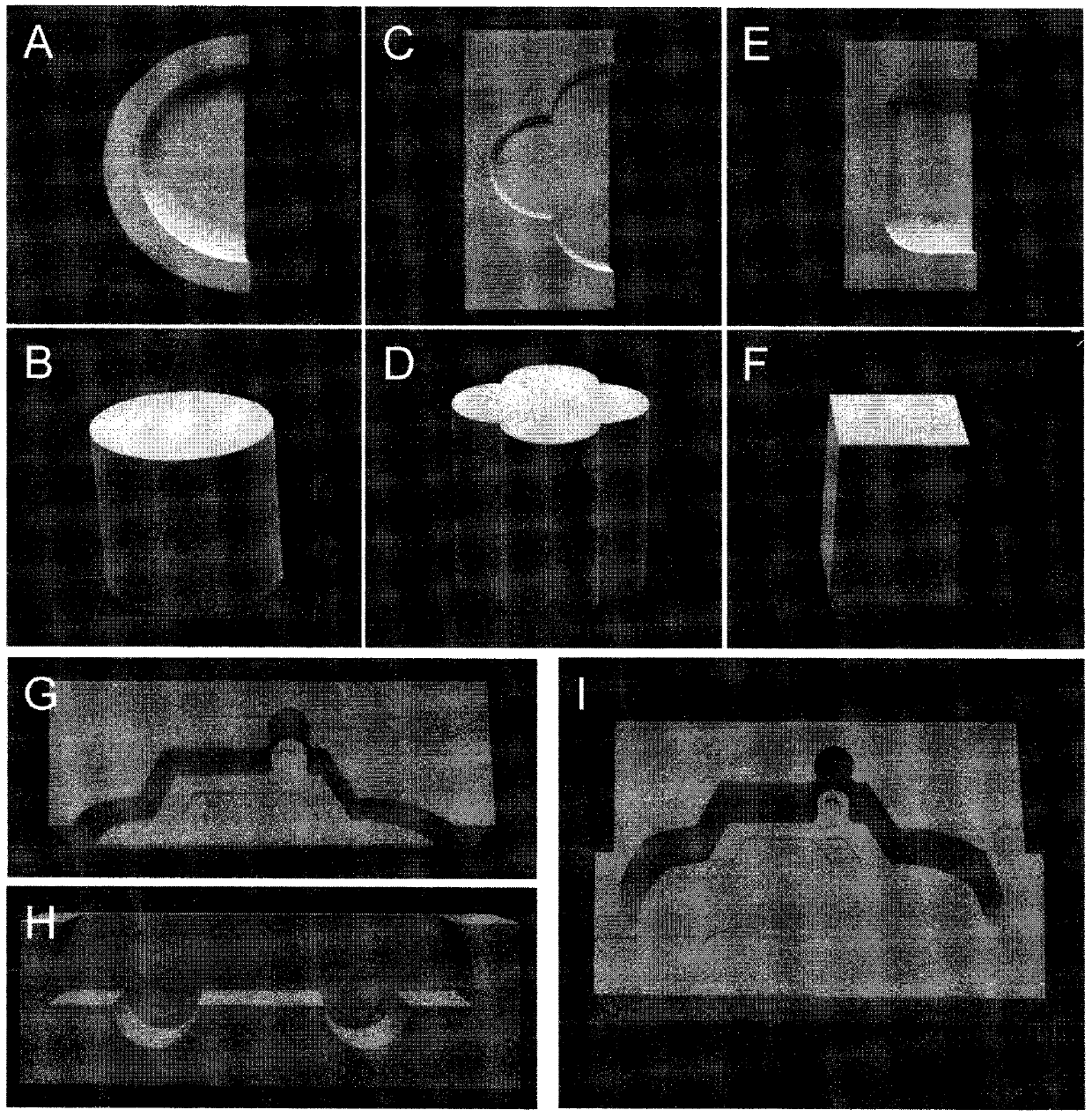

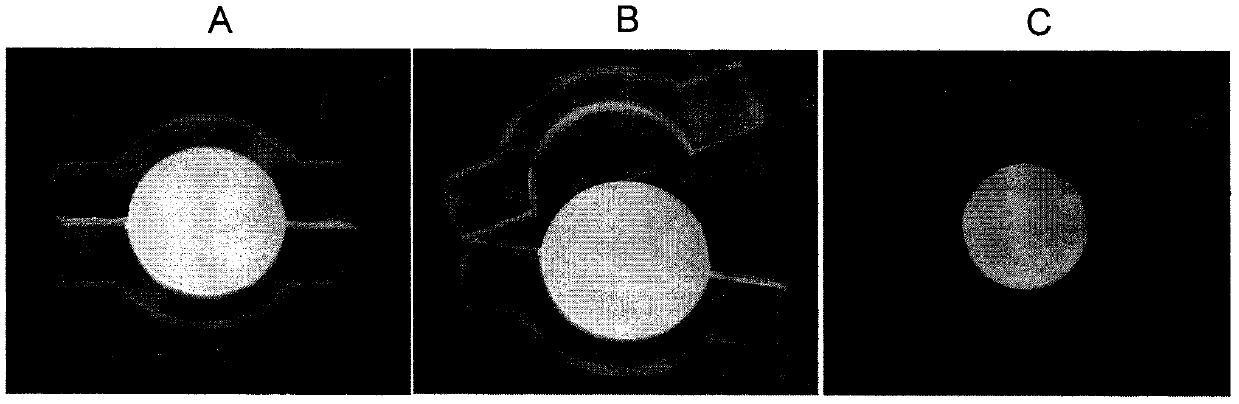

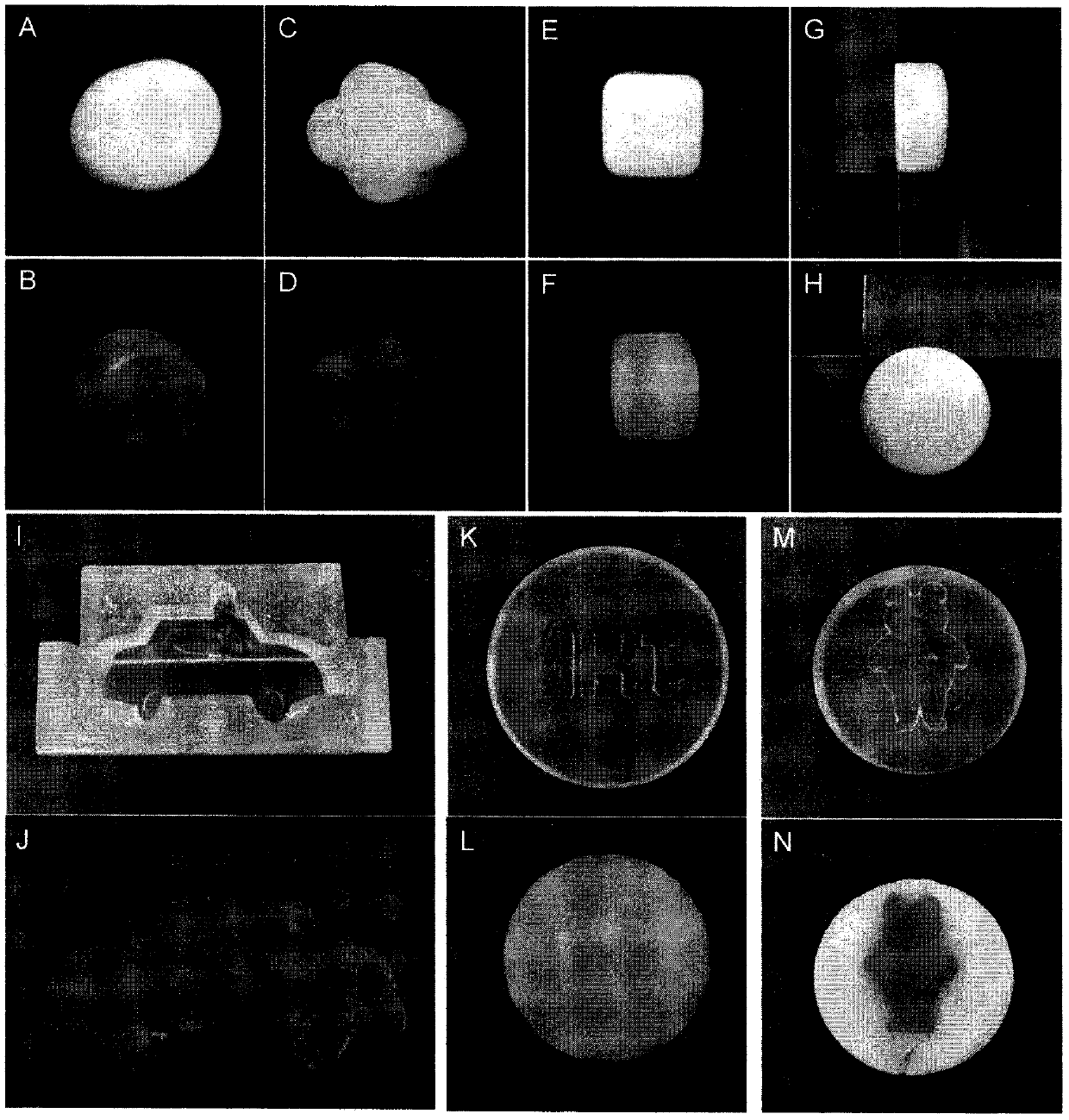

Image

Examples

Embodiment 1

[0021] Example 1. Capsaicin xylitol candy

[0022] Step 1. Candy mold model establishment and printing: use 3D modeling software to build a circular candy mold model complementary to the candy shape, which consists of two symmetrical bases and corresponding pressing covers, and save it as an STL format file; save the STL file Input the slicing software, obtain the slicing file, transfer it to photocuring 3D printing, and print the candy mold with photosensitive resin as the material. After the mold is printed, rinse the residual liquid photosensitive resin on the surface of the mold with absolute ethanol, and get the candy mold after drying;

[0023] Step 2. Preparation of capsaicin xylitol candy: Weigh 0.05 parts of capsaicin, 10 parts of poloxamer 188, and 89.95 parts of xylitol in parts by weight, mix evenly, heat until completely melted, and pour into step 1 while hot Put the prepared candy mold base, compact it with a pressing cover, solidify and demould after cooling to ...

Embodiment 2

[0027] Embodiment 2. capsaicin xylitol embedded pattern candy

[0028] Step 1. Candy mold model establishment and printing: use 3D modeling software to create a circular candy mold model complementary to the shape of the candy, which consists of two symmetrical bases and a pressing cover with raised characters or patterns, and save it as STL Format file; input the STL file into the slicing software, after obtaining the slicing file, transfer it to the photocuring method for 3D printing, and print the candy mold with photosensitive resin as the material. After the mold is printed, rinse the liquid photosensitive resin remaining on the surface of the mold with absolute ethanol. After drying, candy molds are obtained;

[0029] Step 2. Preparation of capsaicin xylitol candy: Weigh 0.05 parts of capsaicin, 10 parts of poloxamer 188, and 89.95 parts of xylitol in parts by weight, mix evenly, heat until completely melted, and pour into step 1 while hot The prepared candy mold base i...

Embodiment 3

[0031] Example 3. Ibuprofen xylitol candy

[0032] Step 1. Candy mold model establishment and printing: use 3D modeling software to build a special shape candy mold model complementary to the shape of the candy, and save it as an STL file; use the STL file to print the candy with polyurethane TPU on the fused deposition method 3D printing mold;

[0033] Step 2, preparation of ibuprofen xylitol: take by weight 5 parts of ibuprofen and 95 parts of xylitol and mix evenly, heat until completely melted, pour into the candy mold prepared in step 1 while hot, and cool Post-curing demoulding to obtain ibuprofen xylitol candy.

[0034] The special shape in the above step 1 can be a five-pointed star, a heart shape, etc. The same effect can be obtained by substituting the above ibuprofen for other drugs. For specific printing models, printing molds, and candies, see Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com