Flue gas waste heat recovery system and method for air pollution control

A flue gas waste heat and recovery system technology, applied in the field of flue gas waste heat recovery, can solve the problems such as the inability to automatically adjust the cold water flow rate of the recovery system, the inability to effectively remove particulate pollutants, and the large volume of the flue gas waste heat recovery system. Compact structure, labor saving, and the effect of improving the heat recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are listed below, and detailed descriptions are as follows in conjunction with the accompanying drawings.

[0049] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

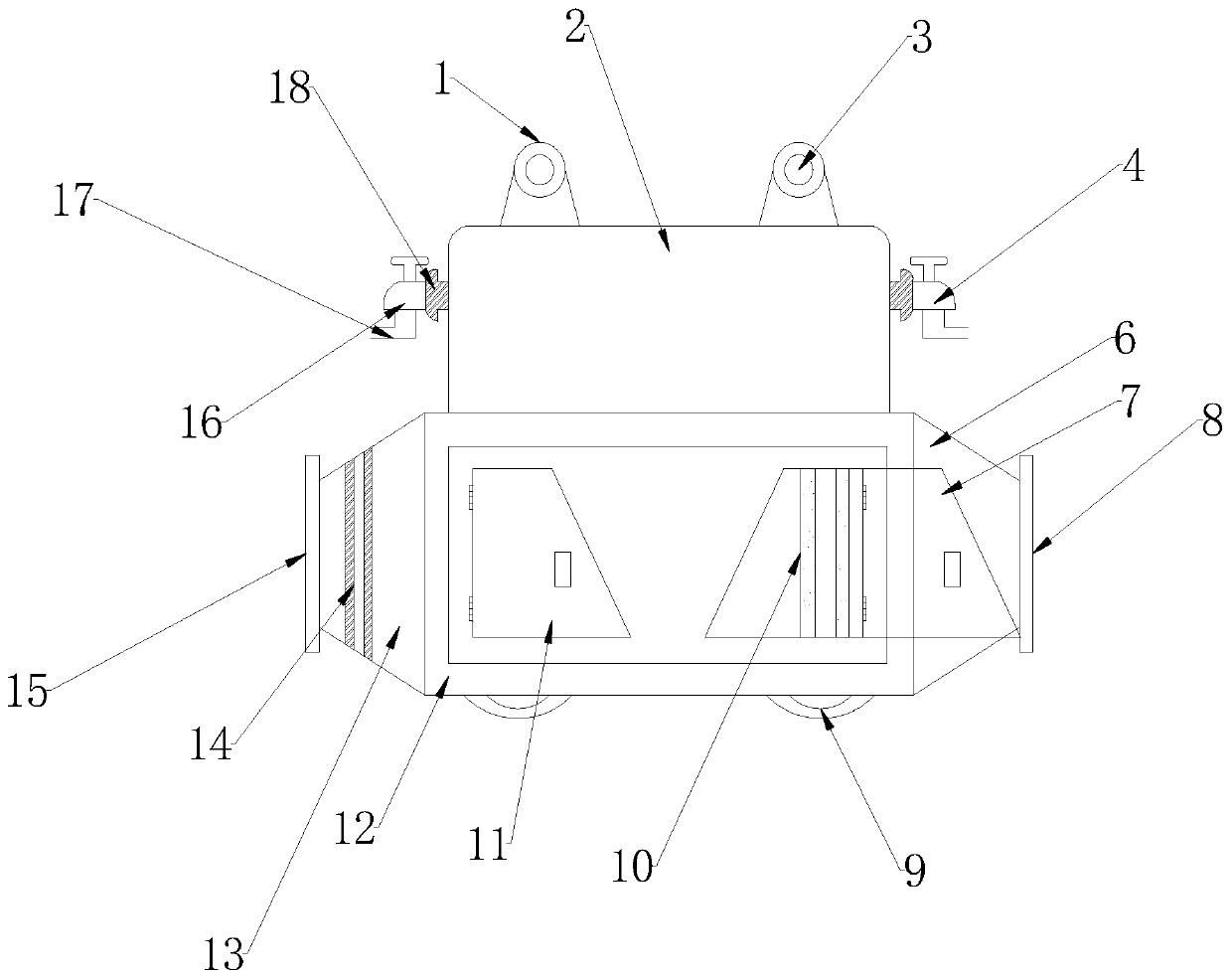

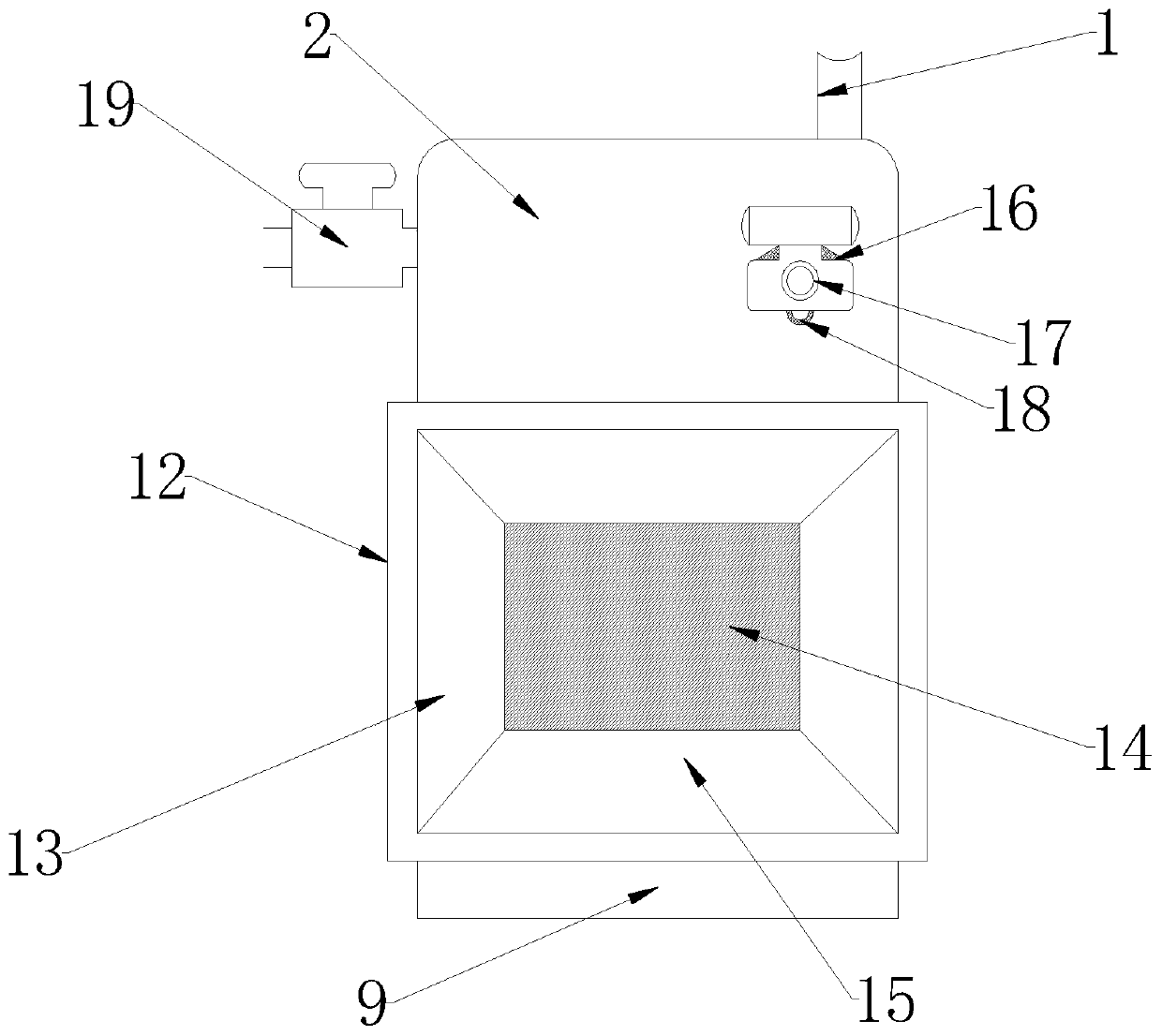

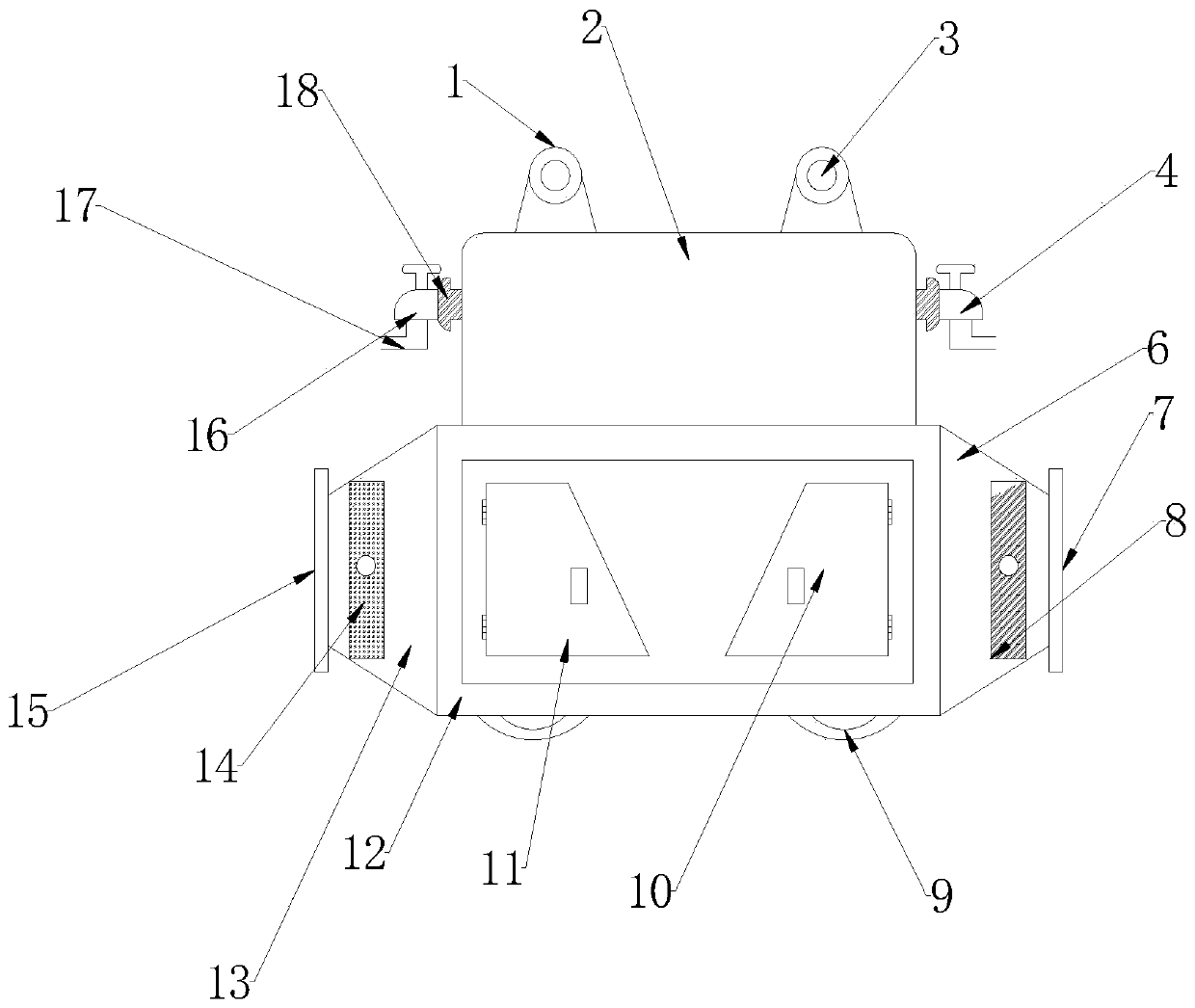

[0050] like Figure 1-Figure 3As shown, the flue gas waste heat recovery device for air pollution control is equipped with a pressure gauge 1, a water tank 2, a thermometer 3, a drain valve 4, a drain pipe 5, a smoke exhaust end cover 6, an activated carbon filter 7, a smoke exhaust port 8, and a base 9. Heat pipe 10, box door 11, cabinet body 12, smoke inlet cover 13, filter cotton layer 14, smoke inlet 15, water inlet valve 16, water inlet pipe 17, pipe ring 18, sewage valve 19.

[0051] The main structure of the flue gas waste heat recovery device for air pollution control is a cabinet body 12, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com