Low-light-transmittance copper-clad laminate and preparation method

A light transmittance, copper-clad laminate technology, applied in chemical instruments and methods, printed circuit manufacturing, circuit substrate materials, etc., can solve the problems of complex preparation methods, high cost, low thermal expansion coefficient of copper-clad laminates, etc., and achieve the preparation method Simple, low light transmittance, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] raw material:

[0037] (A) Epoxy resin, the epoxy equivalent of the epoxy compound is 170~950g / eq. Epoxy resin can be selected from following two kinds of epoxy resins of A-1 and A-2,

[0038] (A-1) Epoxy resin GESR901 of Hongchang Electronic Materials Co., Ltd., epoxy equivalent 450-500g / eq;

[0039] (A-2) o-cresol novolac epoxy resin CNE-202 of Taiwan Changchun Artificial Resin Factory Co., Ltd., epoxy equivalent 202g / eq;

[0040] (B) epoxy resin solidifying agent is dicyandiamide, is purchased from Ningxia Jiafeng Chemical Co., Ltd.;

[0041] (C) The curing accelerator is 2-methylimidazole, purchased from Shikoku Chemical Industry Co., Ltd.;

[0042] (D) Filler, the filler can be selected from the following three types, namely D-1, D-2 and D-3,

[0043] (D-1) Microsilica powder (average particle size is 3 μm, purity is more than 99%);

[0044] (D-2) aluminum hydroxide (average particle diameter is 2 μ m, purity more than 99%);

[0045] (D-3) Degussa carbon black ...

Embodiment 1~5 and comparative example 1~5

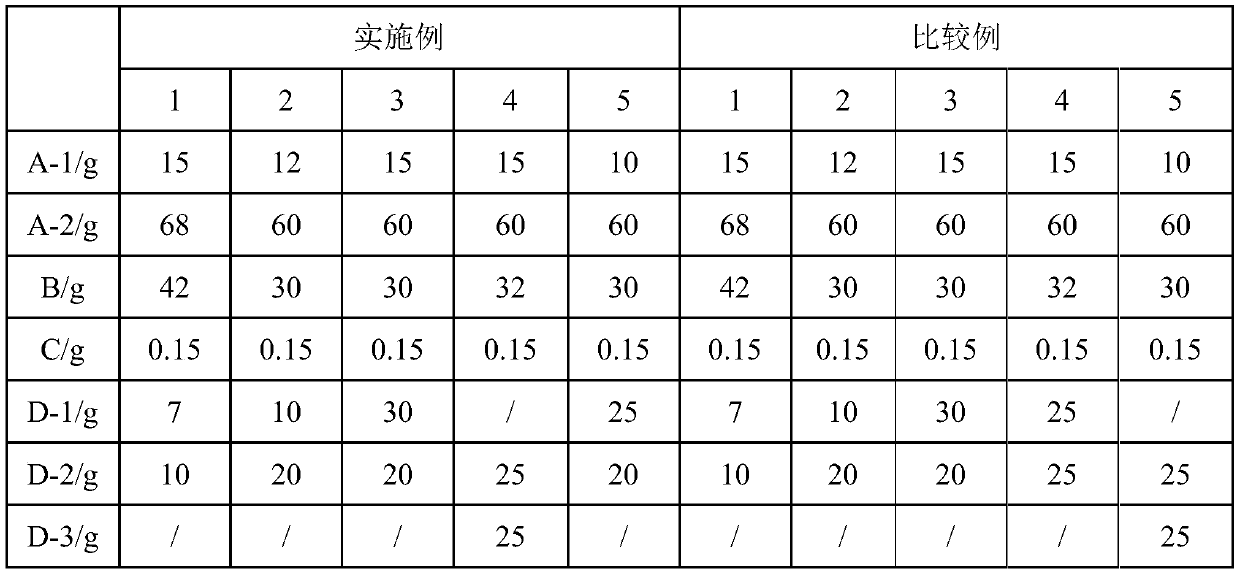

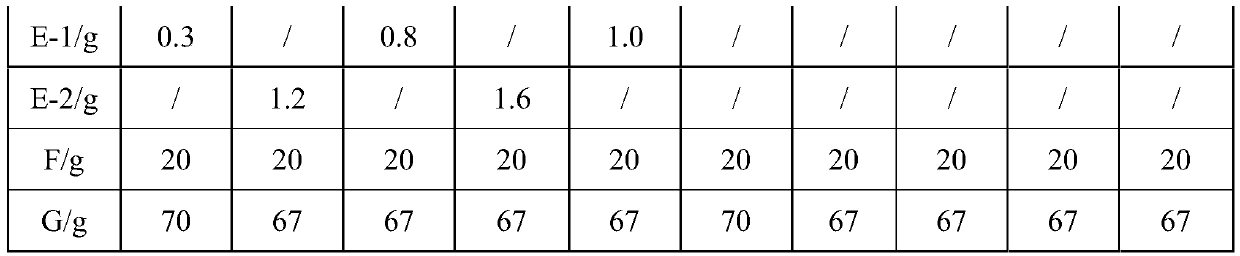

[0056] The raw materials A-1, A-2, B, C, D-1, D-2, D-3, E-1, E-2, F and G in the above embodiment were prepared according to the formula in Table 1. copper plate.

[0057] Table 1 Recipe

[0058]

[0059]

[0060] Among them, Examples 1-5 are copper-clad laminates in which the intermediate layer prepared according to the solution of the present invention contains graphene, and the upper and lower layers are insulating layers. Comparative Examples 1-5 are copper clad laminates obtained by heating and pressing two identical single layers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com