Preparation method and application of anthraquinone compound modified hydrophilic carrier

A technology of hydrophilic carrier and compound, which is applied in the field of preparation of anthraquinone compound modified hydrophilic carrier, which can solve the problems of affecting the compatibility of degrading bacteria, limiting the compatibility of azo dyes, and poor compatibility. , to achieve the effects of low toxicity, reduced usage, and accelerated degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

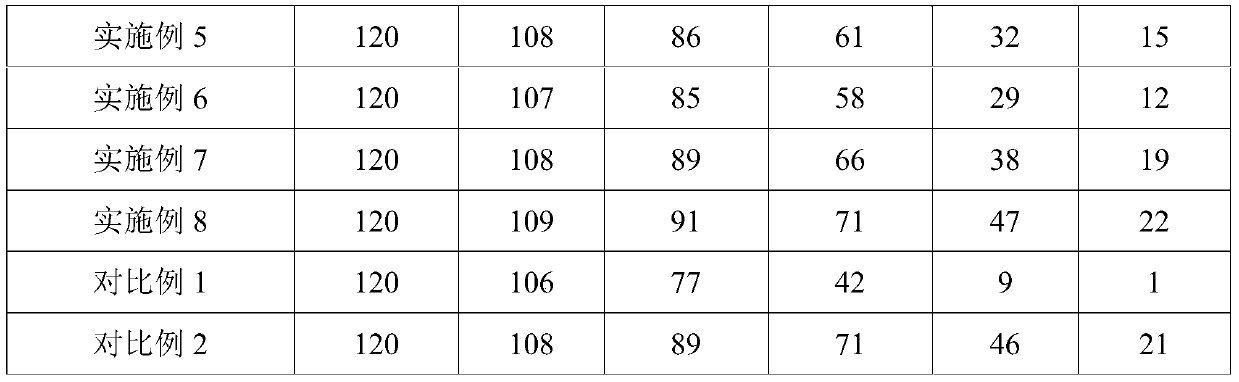

Embodiment 1

[0038] Add 7 parts of 3-(2,3-glycidoxy)propyltrimethoxysilane to 100 parts of alcohol aqueous solution with a volume ratio of 95:5, stir for 0.5 hours, add 25 parts of talc powder with an average particle size of 10 μm, and stir For 1 hour, heat up to 60°C, continue to react for 0.5 hours, filter, filter out the solid, wash it 3 times with absolute ethanol, and dry to obtain epoxy-modified talc powder; the epoxy-modified talc powder is measured by titration. The group content was 0.55 mmol / g.

[0039] Add 100 parts of the above-mentioned epoxy-modified talc powder to 500 parts of tetrahydrofuran, add 9.82 parts of 2-aminoanthraquinone and 0.3 parts of triethylamine, stir for 3 hours, and continue to add 2.2 parts of PEG-NH 2 -200, stirred for 1.5 hours, filtered, the filtered solid was washed three times with absolute ethanol, and dried to obtain hydrophilic talc powder 1 modified with anthraquinone compound.

[0040] FT-IR analysis, product at 1638cm -1 The sharp and strong...

Embodiment 2

[0043] Add 100 parts of epoxy-modified talc powder in Example 1 to 500 parts of tetrahydrofuran, add 8.6 parts of 2-aminoanthraquinone and 0.2 parts of triethylamine, stir for 3 hours, and continue to add 3.3 parts of PEG-NH 2 -200, stirred for 1.5 hours, filtered, the filtered solid was washed three times with absolute ethanol, and dried to obtain hydrophilic talc powder 2 modified with anthraquinone compound.

[0044] It is measured that the anthraquinone content on the anthraquinone compound-modified hydrophilic talc powder 2 is 0.33 mmol / g, and the polyethylene glycol content is 0.14 mmol / g.

Embodiment 3

[0046] Add 100 parts of epoxy-modified talc powder in Example 1 to 500 parts of tetrahydrofuran, add 11 parts of 2-aminoanthraquinone and 0.3 parts of triethylamine, stir for 3 hours, and continue to add 1.1 parts of PEG-NH 2 -200, stirred for 1.5 hours, filtered, the filtered solid was washed three times with absolute ethanol, and dried to obtain anthraquinone compound-modified hydrophilic talc powder 3.

[0047] It is measured that the anthraquinone content on the anthraquinone compound-modified hydrophilic talc powder 3 is 0.43 mmol / g, and the polyethylene glycol content is 0.04 mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com