Water-distribution, gas-distribution and aeration multifunctional filter tube, multifunctional filter tube filter tank, and water treatment method

A multi-functional, filter tube technology, applied in the field of water treatment, can solve the problems that the quantity and quality of aeration bubbles are difficult to guarantee, the structure of the water distribution and air distribution aeration system is complicated, and the aeration volume is difficult to control precisely, and the aeration volume can be achieved. Balanced and consistent, easy and fast installation, independent function effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

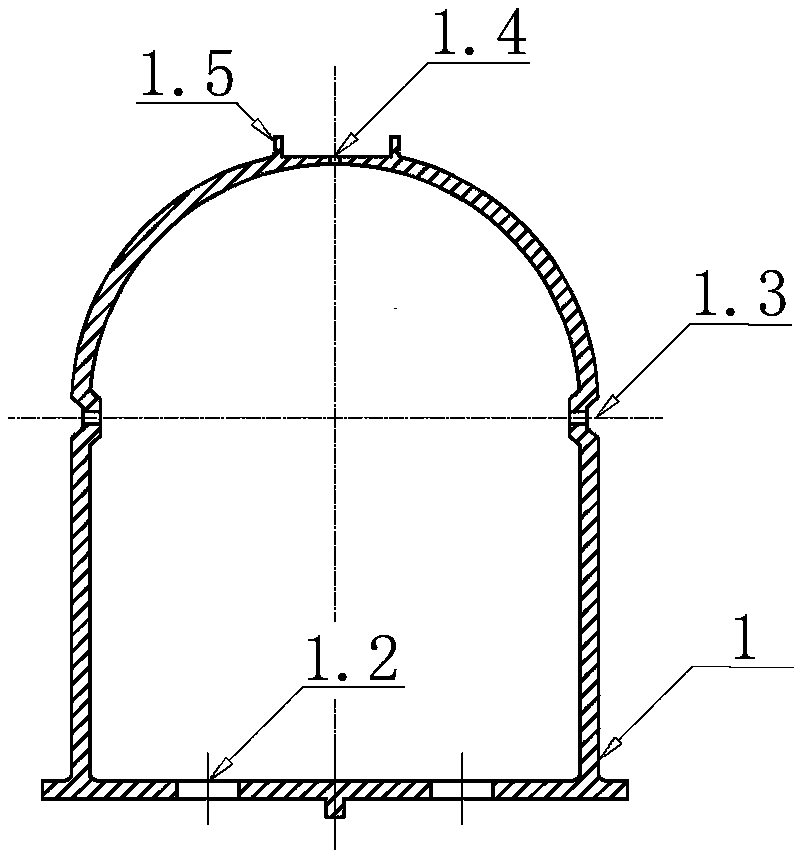

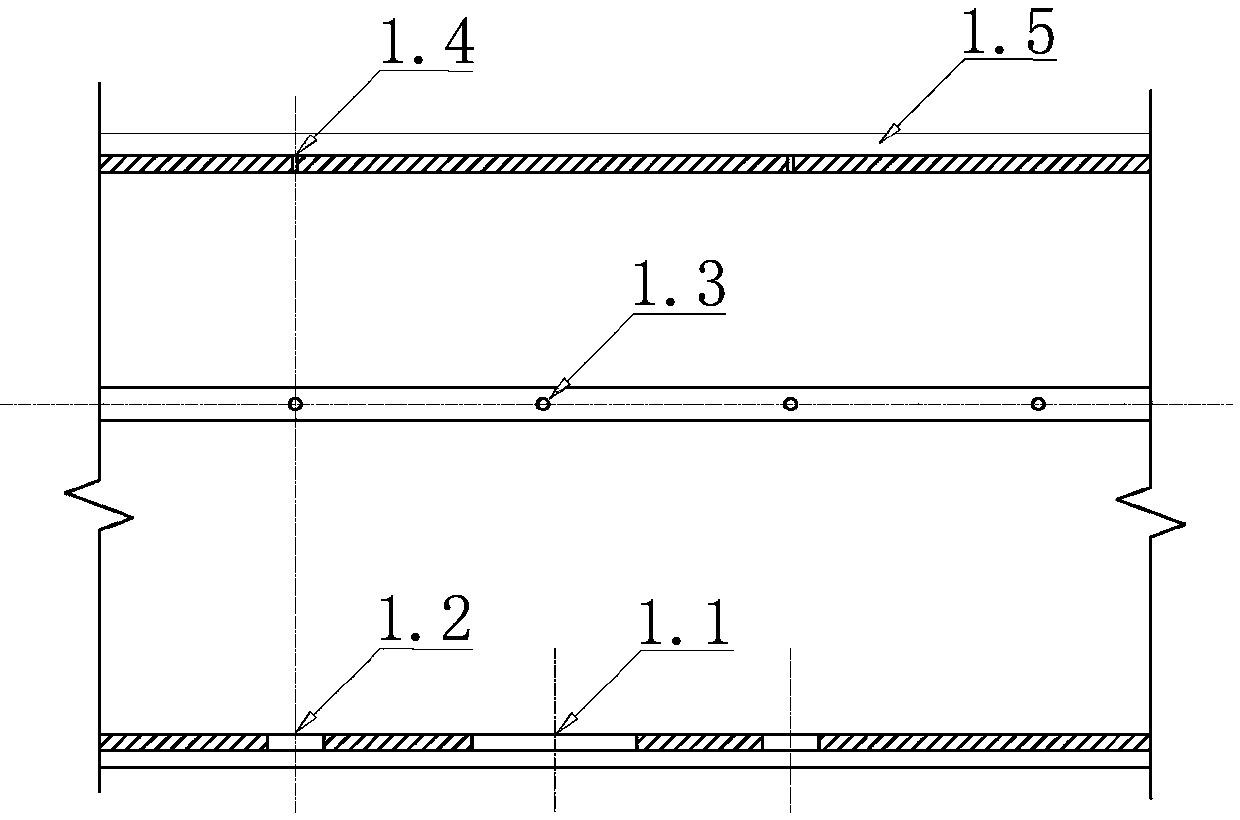

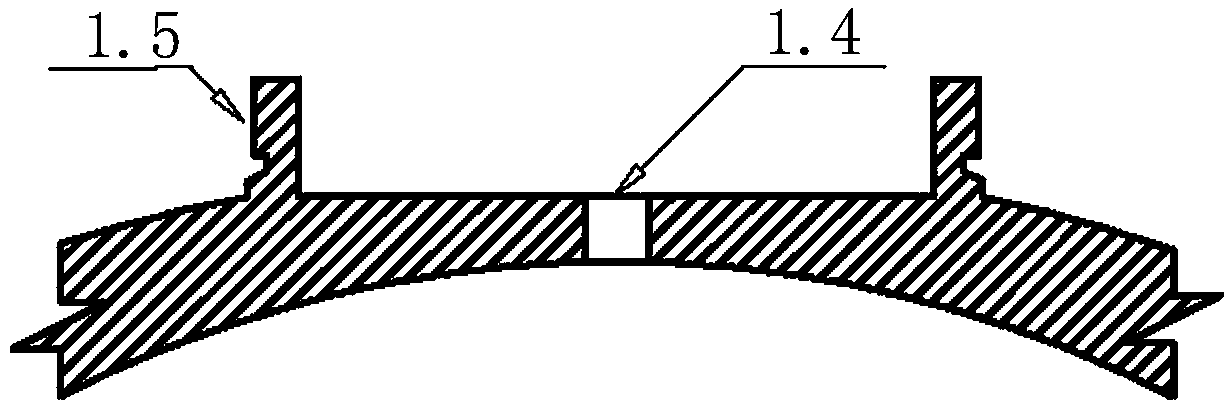

[0048] Examples see Figure 1A , 1B As shown, a multifunctional filter tube for water distribution, gas distribution and aeration, the filter tube 1 is a strip tubular structure, and its cross section is arched; the top of the filter tube 1 is distributed with air distribution holes 1.4 on the top of the filter tube, two The side waist is correspondingly provided with a groove, and the air distribution holes 1.3 on both sides of the filter tube are arranged at the bottom of the groove; the filter pipe water distribution holes 1.2 have two rows, which are symmetrically arranged on both sides of the long axis of the filter tube bottom plate, and the bottom plate is also provided with A vertical pipe insertion hole 1.1; the water distribution holes 1.2 of the filter pipe, the air distribution holes 1.3 on both sides of the filter pipe and the air distribution holes 1.4 on the top of the filter pipe are evenly spaced along the length of the filter pipe 1.

[0049] see figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com