Preparation method of levulinic acid-based liquid fuel

A technology based on levulinic acid and liquid fuels, which is applied in liquid carbon-containing fuels, preparation of carboxylic acid esters, preparation of organic compounds, etc. It can solve problems such as product yield decline, catalytic system or catalyst complexity, and achieve mild reaction conditions , strong adjustable variability, a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

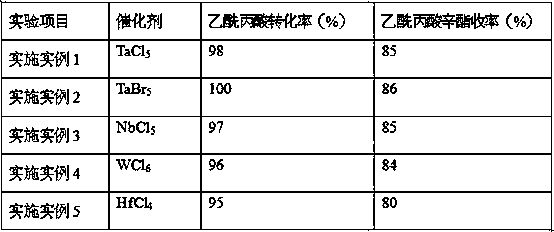

[0022] Add 5 mmol 1-octanol, 1 mmol levulinic acid and catalyst into the reactor, the catalyst is tantalum chloride (TaCl 5 ), tantalum bromide (TaBr 5 ), niobium chloride (NbCl 5 ), tungsten hexachloride (WCl 6 ), hafnium chloride (HfCl 4 ), the amount of catalyst added is 0.05mmol, at 80 o The reaction was carried out at C for 60 min. After the reaction, the samples were tested by gas chromatography, and the conversion rate of raw materials and product yield were calculated.

[0023] Table 1 The results of different catalysts for the synthesis of octyl levulinate from levulinic acid and 1-octanol

[0024]

Embodiment 6~9

[0026] With reference to the step of embodiment example 4, difference is: temperature of reaction is 120 o C and 100 oC , the reaction time was 15 min, and the reaction temperature was 70 o C. 60 o C, the reaction time is 30 min, repeat the above experiments, test samples, calculate the conversion rate of raw materials and product yield.

[0027] Table 2 Results of synthesis of octyl levulinate from levulinic acid and 1-octanol at different temperatures

[0028]

Embodiment 10~12

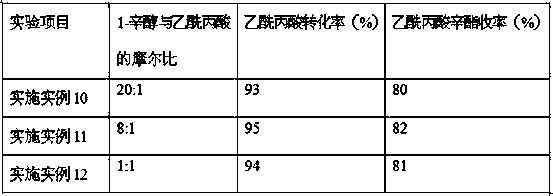

[0030] With reference to the steps of implementation example 4, the difference is: the mol ratio of 1-octanol and levulinic acid is 20:1, 8:1, 1:1, repeat the above experiment, test samples, calculate raw material conversion rate and product yield .

[0031] Table 3 The results of the synthesis of octyl levulinate from levulinic acid and 1-octanol under the conditions of different raw material additions

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com