Flexible flexional active-deicing super-hydrophobic anti-ice-coating composite material and preparation method and application thereof

A composite material and anti-icing technology, applied in the field of anti-icing materials, can solve the problems of reduced anti-icing effect of super-hydrophobic surface, easily damaged rough structure, difficult to achieve large-area preparation, etc., and achieves easy operation and simple preparation method. , the effect of easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

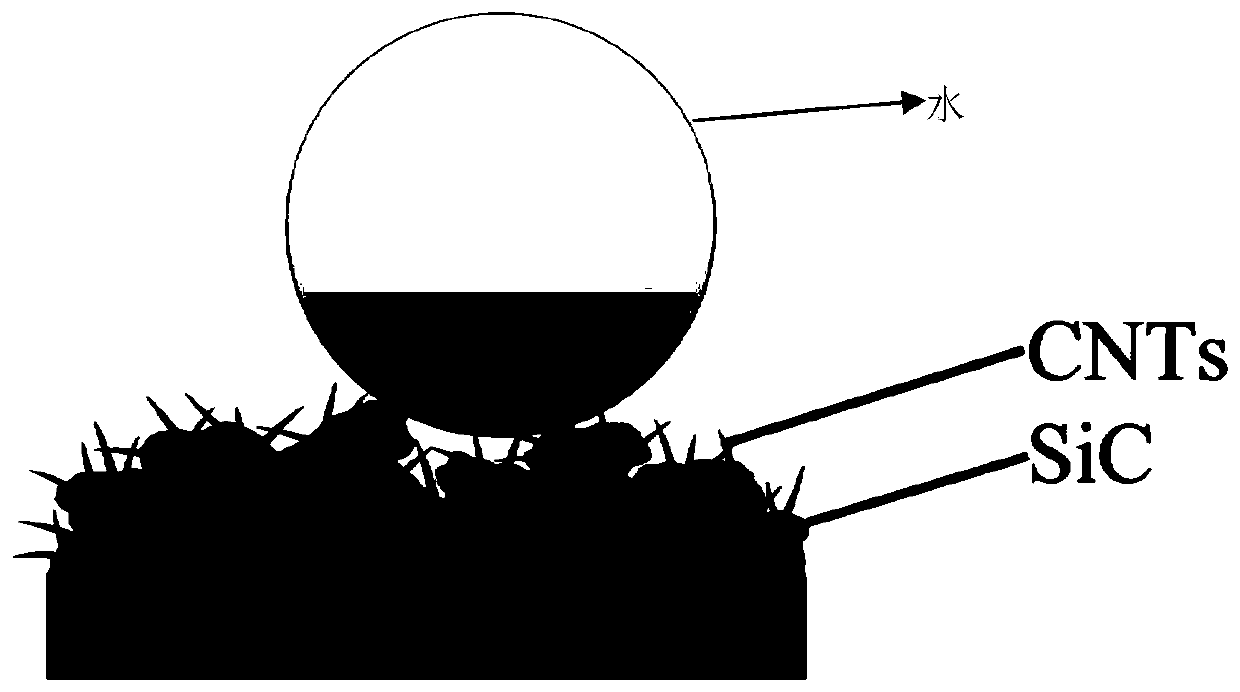

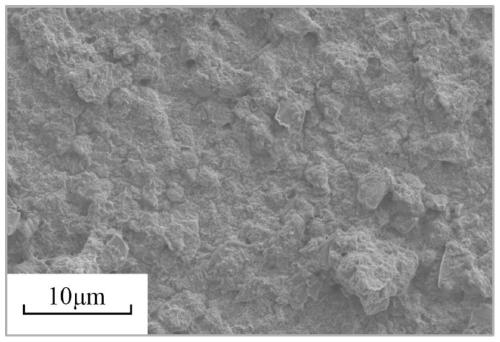

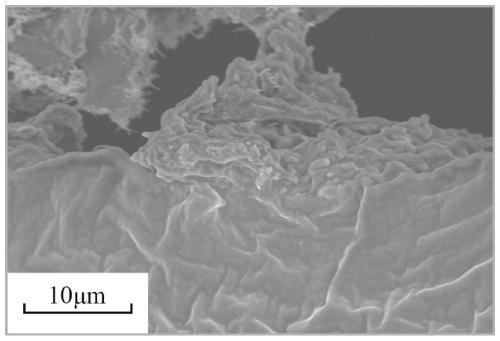

[0039] Weigh 10 g of room temperature vulcanized liquid silicone rubber (SR, brand #107, produced by Jinan Duoweiqiao Chemical Co., Ltd.), add 3 ml of n-hexane, and stir well; production, purity: 98%) as curing agent, add 0.5 milliliters of dibutyltin dilaurate (produced by Shanghai McLean Biochemical Co., Ltd., purity: 98%) as catalyst, stir evenly, the mixture is poured into the cavity volume and is 100mm * 100mm ×3mm polytetrafluoroethylene (PTFE) mold, put it in a vacuum oven and evacuate it for 10 minutes to remove air bubbles, take it out and put it in a blast drying oven at 50°C for 40 minutes, wait for the surface to enter a semi-cured state, and obtain a semi-cured Cured silicone rubber; take by weighing 20 mg of carboxylated multi-walled carbon nanotubes (CNTs, produced by Nanjing Xianfeng Nano Material Technology Co., Ltd., average diameter: 100 nm, length: 10-20 microns, purity: 95%), silicon carbide micropowder (SiC, produced by Shandong Jinmeng New Material Compa...

Embodiment 2

[0043] Weigh 10 grams of room temperature vulcanized liquid silicone rubber (SR, grade #107), add 3 milliliters of n-hexane, and stir well; add 1 milliliter of tetraethyl orthosilicate as curing agent, add 0.5 milliliters of dibutyltin dilaurate as catalyst, and stir Evenly, pour the mixture into a polytetrafluoroethylene (PTFE) mold with a cavity volume of 100mm×100mm×3mm, put it in a vacuum oven and evacuate it for 10 minutes to remove air bubbles, take it out and put it in a blast drying oven at 50°C Place in the middle for 40min, wait for the surface to enter the semi-cured state; weigh carboxylated multi-walled carbon nanotubes (average diameter: 100 nanometers, length: 10-20 microns, purity: 95%) 20 mg, silicon carbide micropowder 10 mg, add to In 100 ml of absolute ethanol, add 2 ml of ethyl orthosilicate, 100 microliters of perfluorodecyltrimethoxysilane, and ultrasonically disperse for 30 minutes to obtain a suspension; use a spray gun to vertically Spray on the semi-...

Embodiment 3

[0048] Weigh 10 grams of room temperature vulcanized liquid silicone rubber (SR, grade #107), add 3 milliliters of n-hexane, and stir well; add 1 milliliter of tetraethyl orthosilicate as curing agent, add 0.5 milliliters of dibutyltin dilaurate as catalyst, and stir Uniform; pour the mixture into a polytetrafluoroethylene (PTFE) mold with a cavity volume of 100mm×100mm×3mm, put it in a vacuum oven and evacuate it for 10 minutes to remove air bubbles, take it out and put it in a blast drying oven at 50°C Place in the middle for 40min, wait for the surface to enter a semi-cured state; weigh carboxylated multi-walled carbon nanotubes (average diameter: 100 nanometers, length: 10-20 microns, purity: 95%) 20 mg, silicon carbide micropowder 100 mg, add to In 100 ml of absolute ethanol, add 2 ml of ethyl orthosilicate, 100 microliters of perfluorodecyltrimethoxysilane, and ultrasonically disperse for 30 minutes to obtain a suspension; use a spray gun to vertically Spray on the semi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com