Ordered closed type micro-nano composite structure anti-icing surface and preparation method thereof

A micro-nano composite structure, closed technology, used in manufacturing tools, welding equipment, laser welding equipment, etc., can solve the problems of insufficient controllability of micro-nano structures, complex preparation steps, material limitations, etc., to achieve flexibility, green environmental protection , Low preparation cost, and the effect of reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

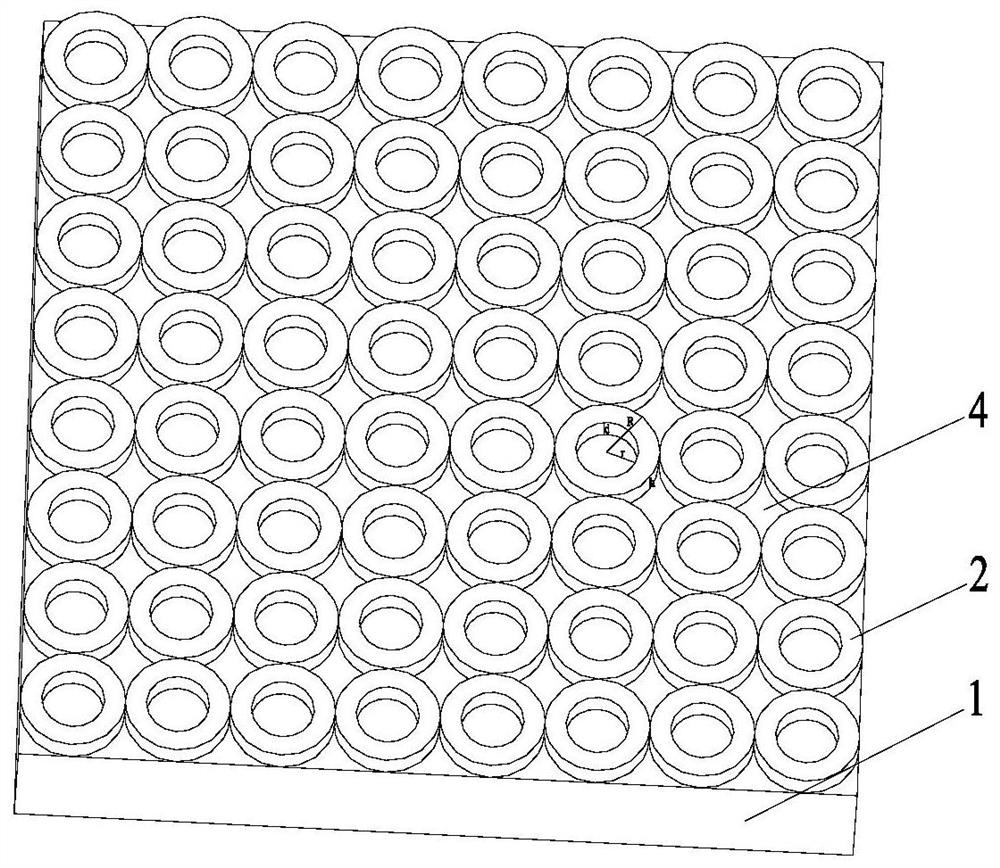

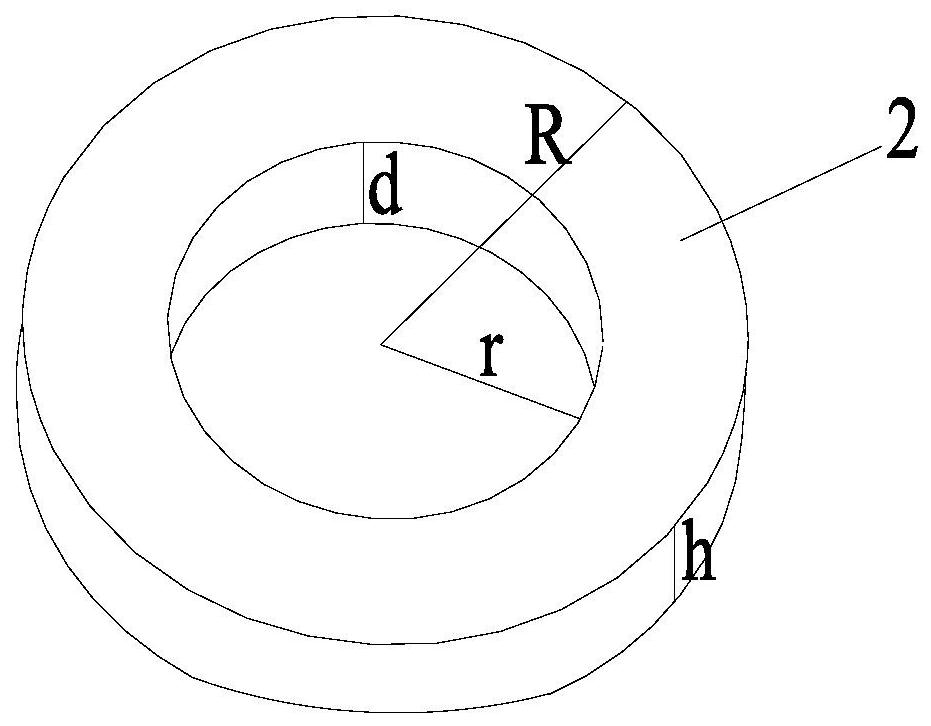

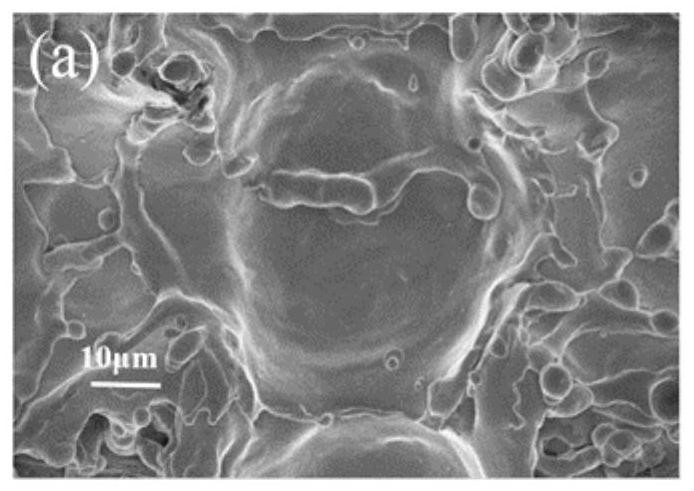

[0043] see figure 1 and figure 2 , an orderly closed micro-nano composite anti-icing surface of this embodiment, including a plurality of tangential periodic tubular microstructures 2 distributed on the metal substrate 1, the material of the metal substrate 1 can be selected but not limited to Titanium alloy, aluminum alloy and other metals. A plurality of tubular microstructures 2 of the same shape and size are arranged in an orderly manner on the surface of the metal substrate and are periodically and repeatedly arranged on the metal substrate 1. Adjacent tubular microstructures 2 are tangent to each other, and the entire metal substrate All the tubular microstructures on the 1 are pressed against each other to fill the entire surface of the metal substrate 1 . The tubular microstructure 2 is provided with a nanostructure 3, the tubular microstructure 2 and the nanostructure 3 form a micro-nano composite structure, there is an air gap 4 between the tubular microstructures...

Embodiment 2

[0049] refer to Figure 6 As shown, this figure schematically shows the flow chart of the preparation of the micro-nano composite structure on the metal surface. This embodiment 2 provides an orderly closed micro-nano composite structure anti-icing surface preparation method, including the following steps:

[0050] S1: Polish and clean the metal substrate to be processed; the metal substrate in the step S1 is titanium alloy, aluminum alloy or other metals, and the polishing step is to use 200#, 500# and 1000# sandpaper on the metal surface Carry out polishing and polishing. The cleaning method is to use deionized water to rinse the residue on the polished metal surface, and put it in absolute ethanol for ultrasonic cleaning for five minutes. After taking it out, rinse the residual absolute ethanol on the surface with deionized water, nitrogen Blow dry the metal surface.

[0051] S2: Reference Figure 7 , which shows a schematic diagram of the laser processing system. Utiliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Feature size | aaaaa | aaaaa |

| Height h | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com